Strength testing device and testing method for fuselage wall plate under action of combined loads

A fuselage panel, strength test technology, applied in the direction of measuring device, strength characteristics, using a stable shear force to test the strength of materials, etc., can solve problems such as large limitations, and achieve the effect of reducing boundary effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below by specific embodiment the present invention is described in further detail:

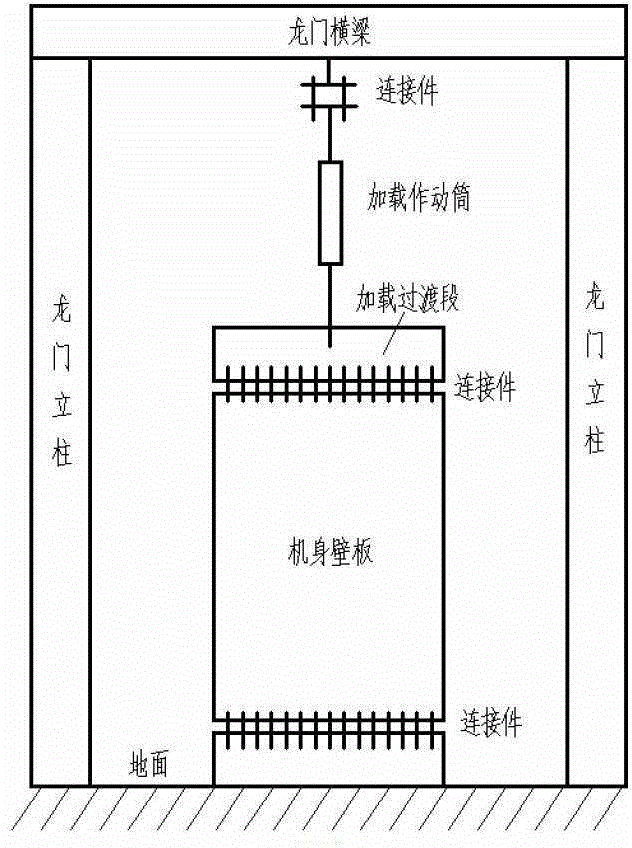

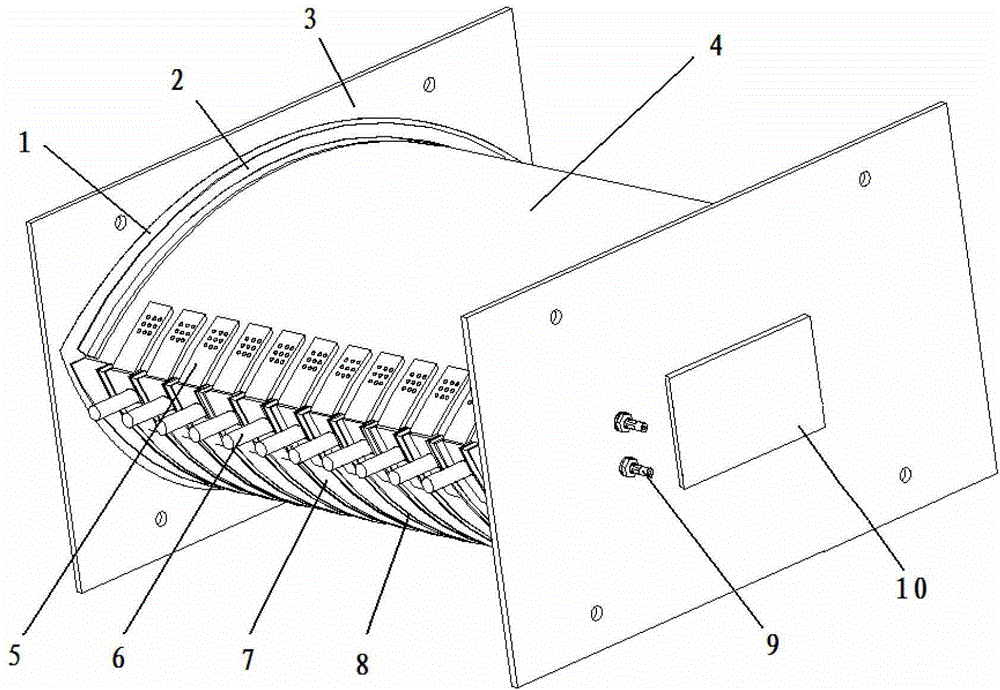

[0044] see figure 2 , which is a structural schematic diagram of the fuselage panel composite load strength test device of the present invention. The fuselage panel composite load strength test device is mainly composed of annular rubber pad 1, corner box 2, airtight end plate 3, hinge 5, ejector rod 6, keel 7, curved rubber plate 8, pressure joint 9, Nine parts such as the manhole cover plate and the fuselage wall plate 4 are assembled through bolt connection or adhesive connection.

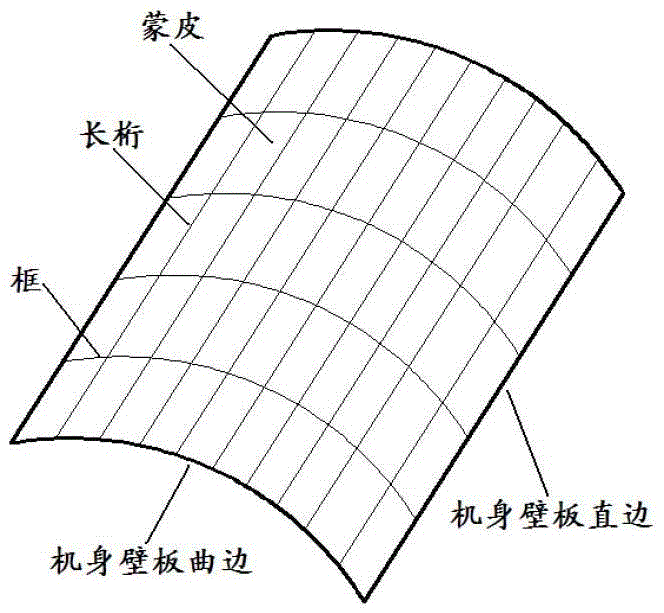

[0045] Such as image 3 As shown, the fuselage panel refers to a fuselage structure selected from the fuselage cylinder including 5 to 9 stringers, 5 frames and a piece of skin.

[0046] The application of compound load means that one, two or three of internal pressure load, tension (or compression) load and shear load can be applied. Because the tensile load and the compressive load cannot be applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com