Children special-shaped board book automatic page turning punching production line

A technology of automatic page turning and production line, applied in book binding, composite continuous process of book processing, printing and other directions, can solve the problems of long production cycle and high labor intensity, achieve high degree of automation, reduce labor intensity, and work process Continuous and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

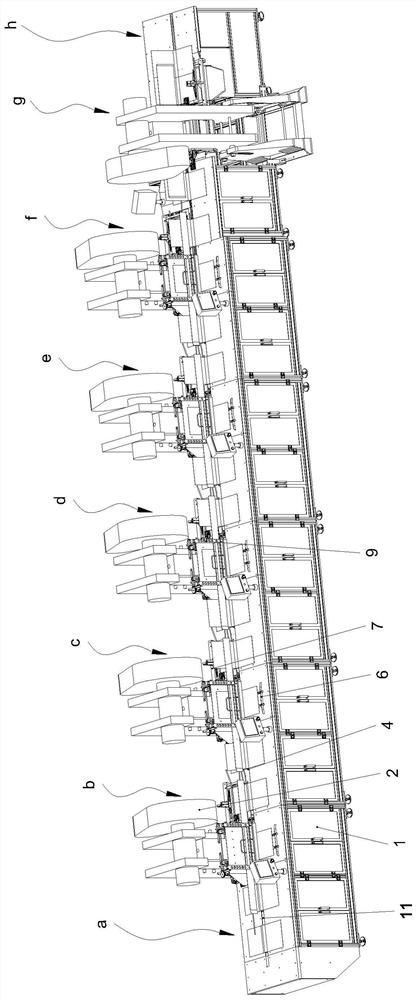

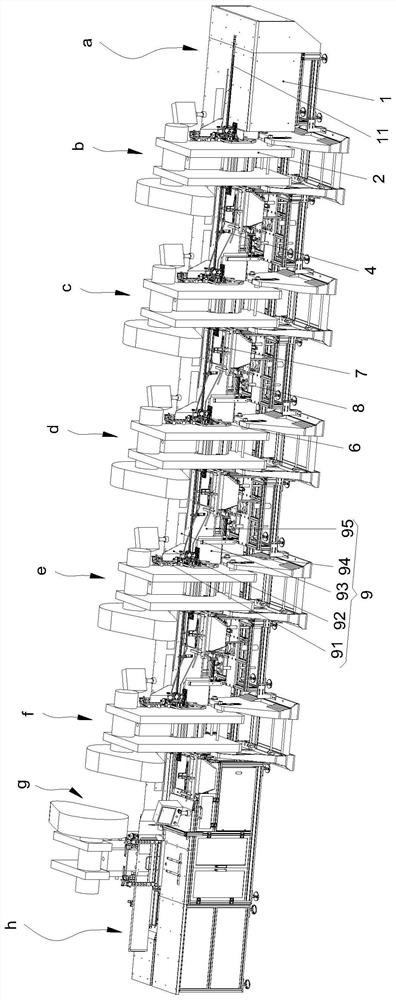

[0032] refer to Figure 1-7 , the automatic page-turning and punching production line for children's special-shaped card books of the present invention includes a workbench 1, a punching machine 2, a pushing device 4, a sensor 5, a snapping device 6, a waste cleaning device 7, a page turning device 8, a book guide device 9 and a control The controller, the controller is electrically connected with the punch press 2, the push device 4, the sensor 5, the clapping device 6, the waste removal device 7, and the page turning device 8 respectively, and the controller can be a control panel including a PLC control system, through The input parameters enable the control panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com