Multidimensional radial pressure measuring device of underground sucker rod

A radial pressure and measuring device technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve problems such as the difficulty in determining the radial force of sucker rod eccentric wear, and achieve high-precision real-time measurement, strong environmental adaptability, volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

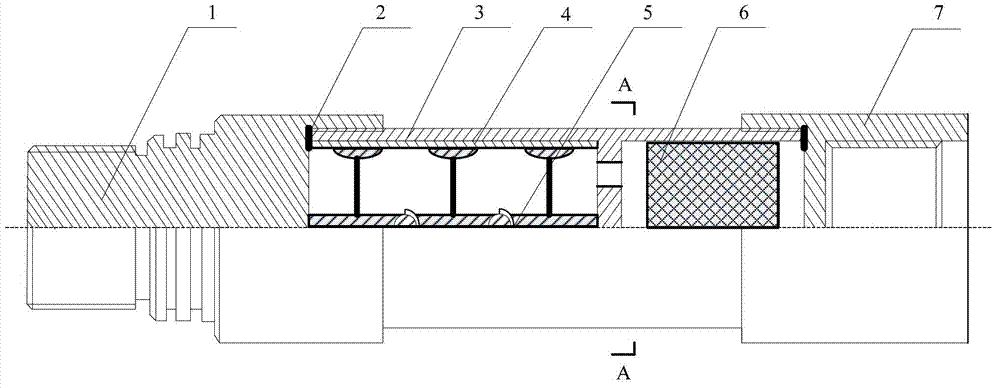

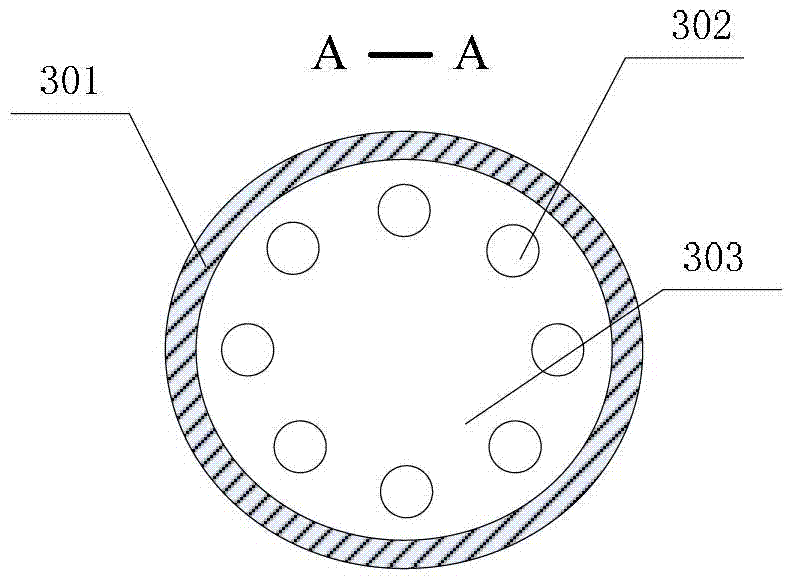

[0035] see figure 1 , Figure 8 A downhole sucker rod multi-dimensional radial pressure measuring device is composed of a downhole component and an uphole attachment. The position connection relationship between them is: when the measuring device performs downhole measurement, the downhole components and the uphole accessories are separated from each other and work independently. The data sampling frequency, the uphole accessory part analyzes and processes the radial force data of the sucker rod in the previous period; when the measuring device is located on the wellbore for data analysis, the downhole component and the uphole accessory are connected through the data communication interface 605 using a serial line, from Large-capacity FLASH memory 604 transfers downhole measurement data.

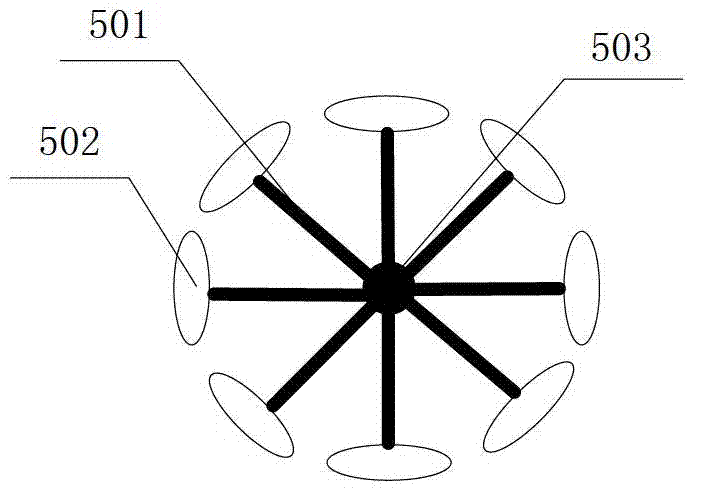

[0036] The present invention will be described in further detail below. The present invention uses strain gauge sensors to build a bridge-type measurement circuit 609, which is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com