Concrete grinding system for roll squeezer and grinding method thereof

A roller press and grinding technology, which is applied to the roller press cement final grinding system and its grinding field, can solve the problem of high grinding energy consumption, and achieve the effect of reducing metal material wear and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

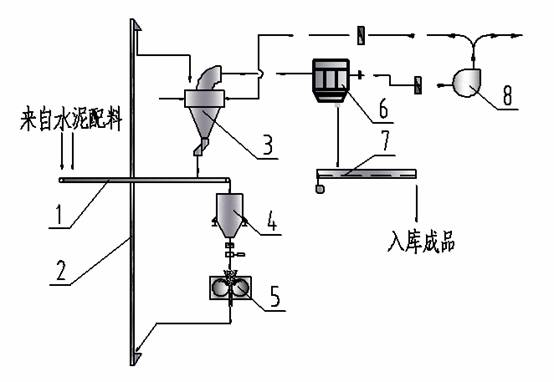

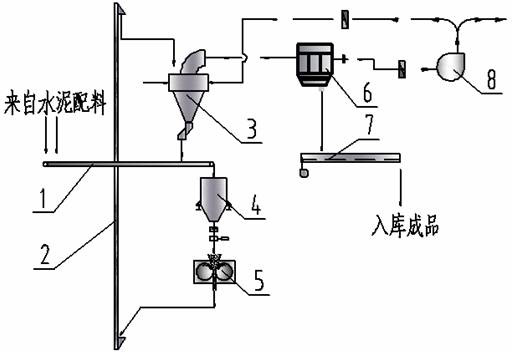

[0011] Such as figure 1 As shown, the roller press cement final grinding system of the present invention includes a belt conveyor (1), a bucket elevator (2), a powder separator (3), a steady flow bin (4), and a roller press (5), bag filter (6), belt conveyor (7) and circulation fan (8), the belt conveyor (1) is provided with a feed port and a discharge port; powder classifier (3) There is a material inlet and a material outlet on the top; the steady flow bin (4) is equipped with a material inlet and a material outlet; the roller press (5) is equipped with a material inlet and a material outlet; the belt conveyor The discharge port of (1) is connected with the feed port of the steady flow bin (4), the discharge port of the steady flow bin (4) is connected with the feed port of the roller press (5), and the feed port of the roller press (5) The outlet is connected to the bucket elevator (2), the bucket elevator (2) is connected to the feed port of the powder separator (3), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com