Full-automatic feeding and discharging and multi-station appearance detecting and sorting equipment and method for small parts

A visual inspection, multi-station technology, applied in sorting, conveyor objects, sustainable manufacturing/processing, etc., can solve the problems of uninspectable types, low inspection efficiency, high cost, etc., and achieve a compact and intelligent overall layout design. The effect of improved degree of automation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

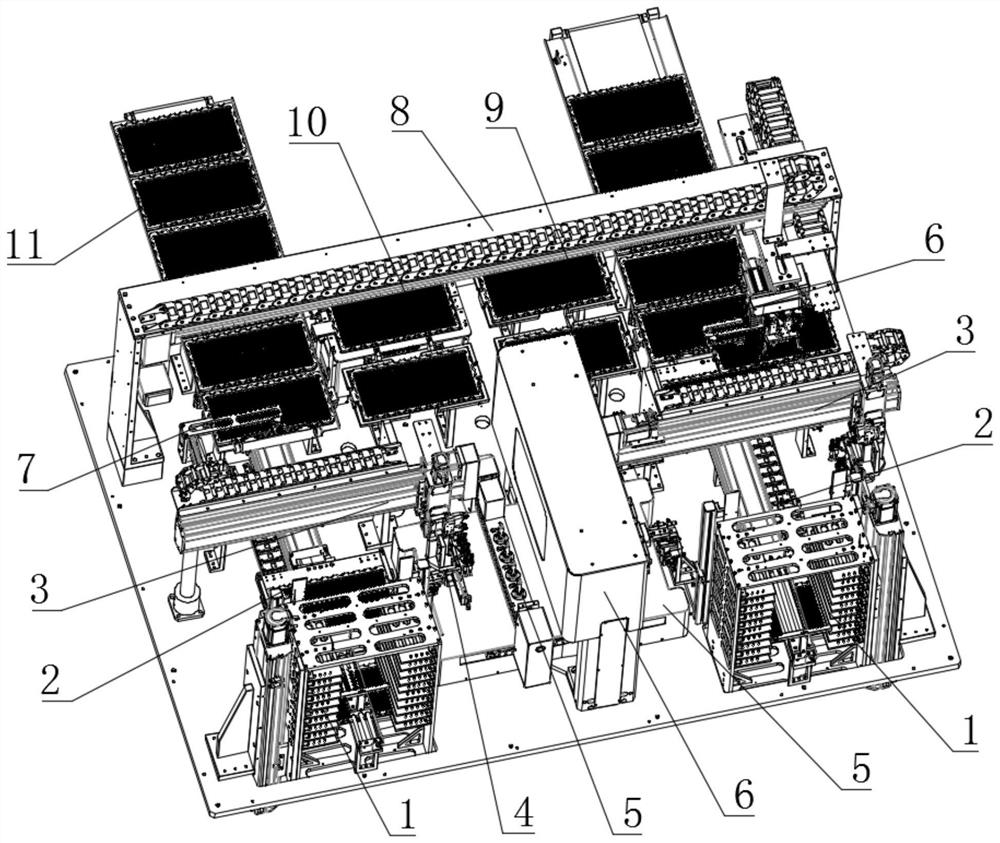

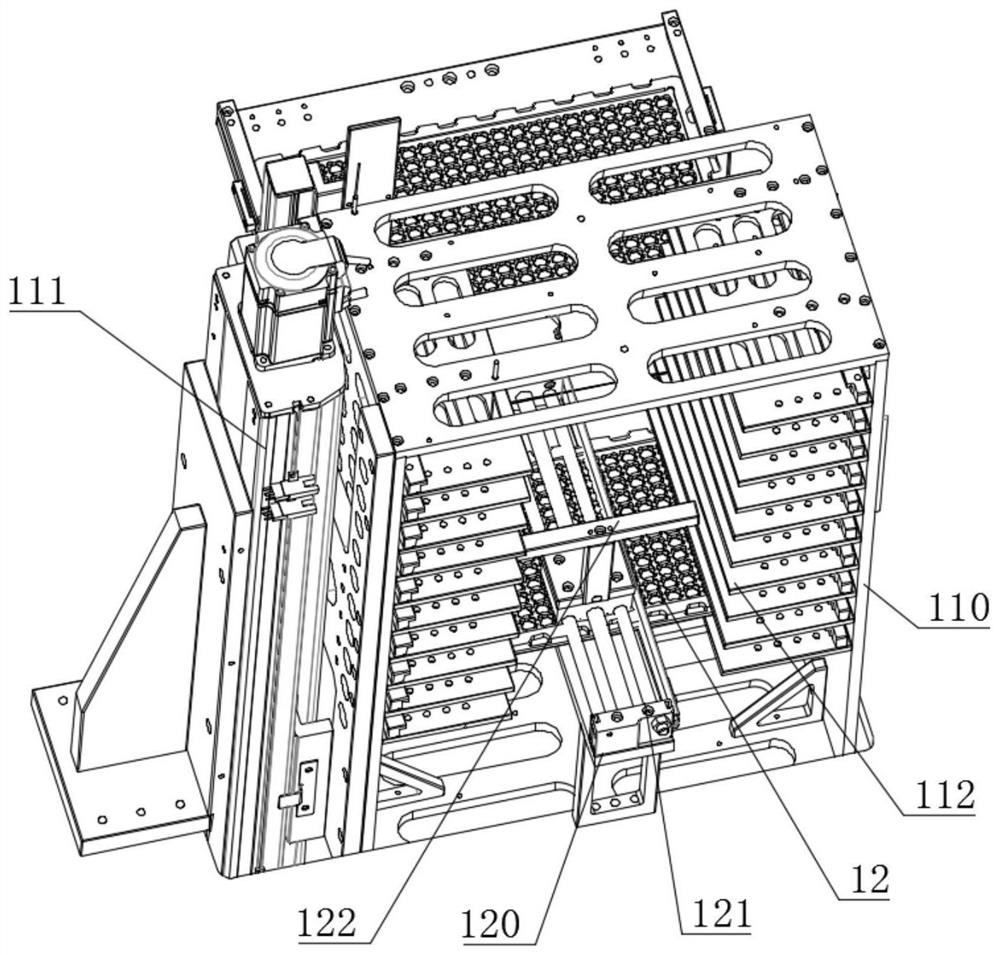

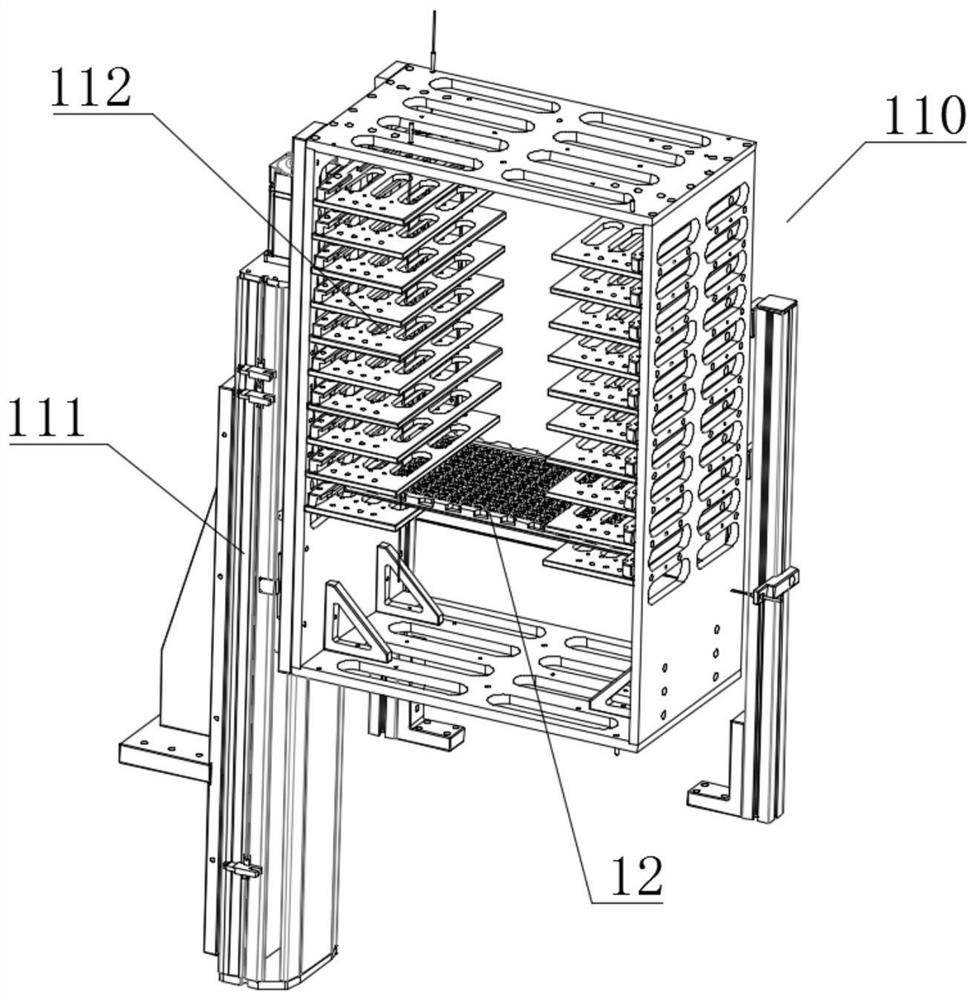

[0050] Fully automatic loading and unloading and multi-station small parts appearance inspection and sorting equipment, such as figure 1 As shown, it includes tray loading mechanism 1, product loading and unloading station 2, product transplanting mechanism 3, product secondary positioning station 4, product inspection stage 5, product inspection station 6, sorting and refilling workers Position 7, OK product and NG product sorting mechanism 8, NG product placement station 9, OK product replenishment placement station 10, OK product whole plate output mechanism 11.

[0051] The tray feeding mechanism 1 is used to transport the tray to the product loading and unloading station 2, and the products to be detected are arranged and fixed in the tray; the product loading and unloading station 2 is positioned by the tray to perform product Coarse positioning, so that the product transplanting mechanism 3 can take and place the products in the tray, and at the same time transport the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com