Integrated optimization control method for circulating water system

A circulating water system and optimized control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of non-optimized energy consumption, and achieve the effect of energy saving in operation and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

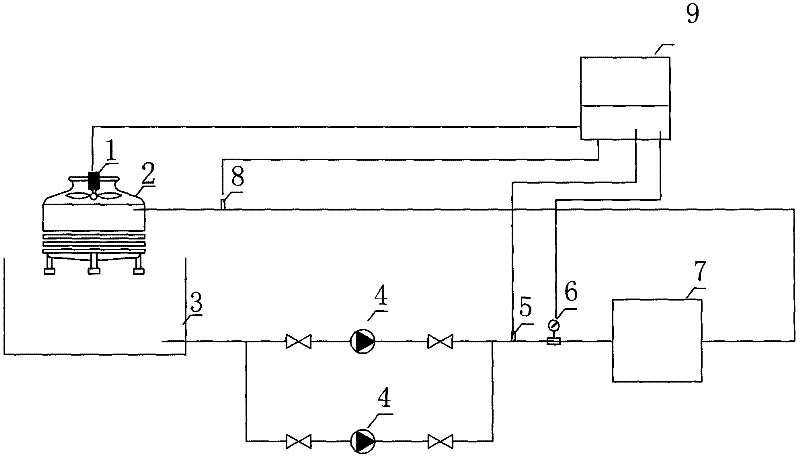

[0062] According to attached figure 1 As shown in the structure, a cooling tower device is installed, including: cooling tower fan 1, cooling tower 2, cold water pool 3, two cooling water pumps 4, cooling equipment inlet temperature instrument 5, cooling water flow meter 6, cooling equipment 7, cooling Equipment outlet temperature instrument 8, and control device 9.

[0063]Step (1) Measure the operating characteristic indicators of the circulating water system through the instruments and equipment installed on the cooling tower, and establish a real-time temperature and water flow database; the specific measured operating parameters include: the inlet temperature of the cooling equipment of the circulating water system, the outlet temperature, Flow rate, actual power of circulating water pump, actual power of cooling tower fan, atmospheric temperature, humidity;

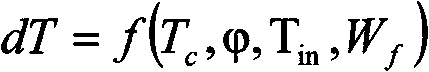

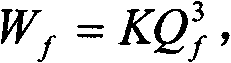

[0064] Step (2) establishes the mathematical model of the cooling effect of the cooling tower according to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com