Heat exchanger

A technology of heat exchangers and fins, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of small temperature difference, difficult heat exchange, and difficult heat exchange between air intake and cooling air And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

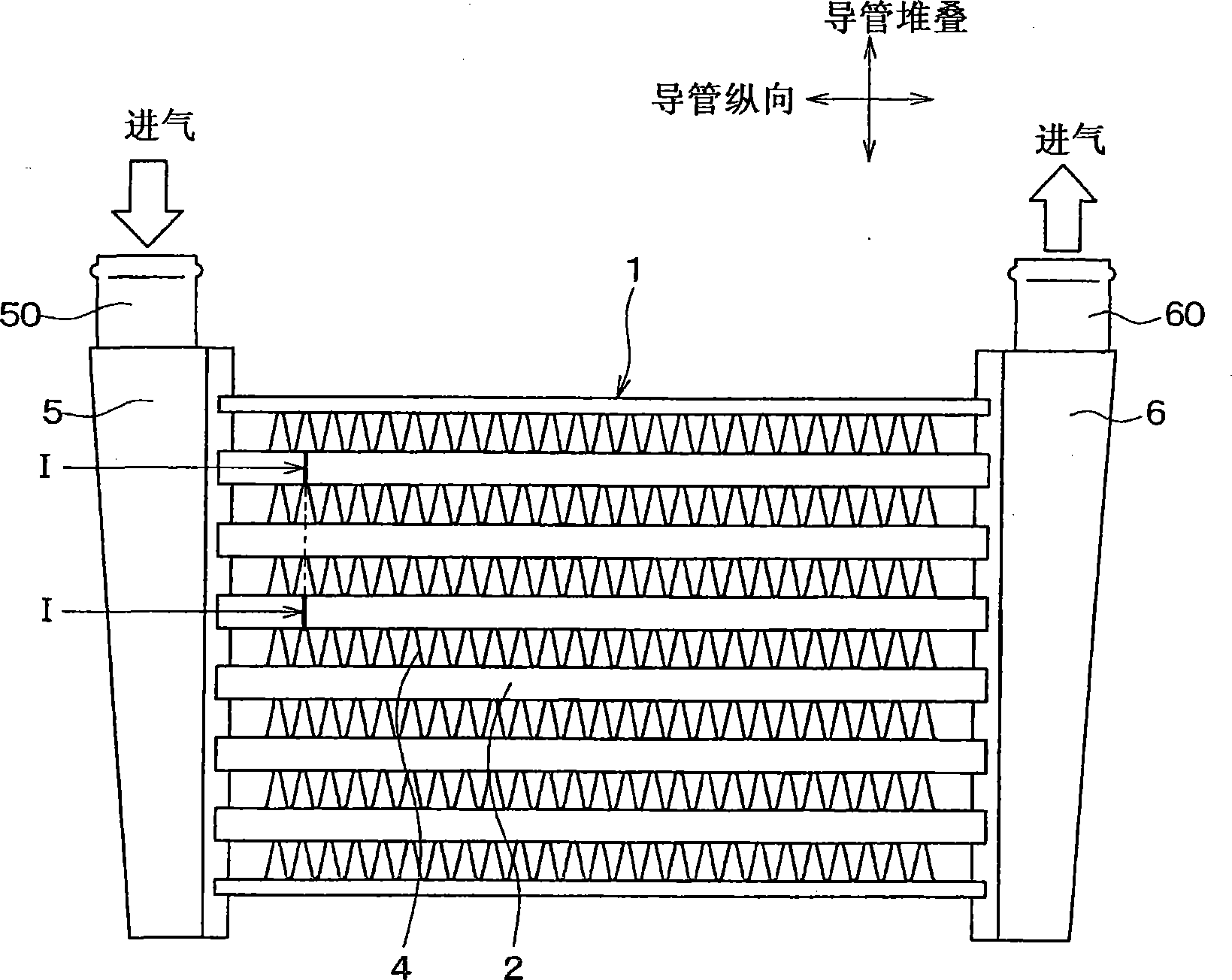

[0029] refer to Figure 1 ~ Figure 4 A first embodiment of the present invention is described below. The heat exchanger according to the first embodiment of the present invention is typically used for an intercooler. The intercooler is configured to perform heat exchange between outside air (cooling air) and intake air for combustion to be input into the internal combustion engine, thereby cooling the intake air. The intake air is an example of the first fluid of the present invention, and cooling air is an example of the second fluid of the present invention.

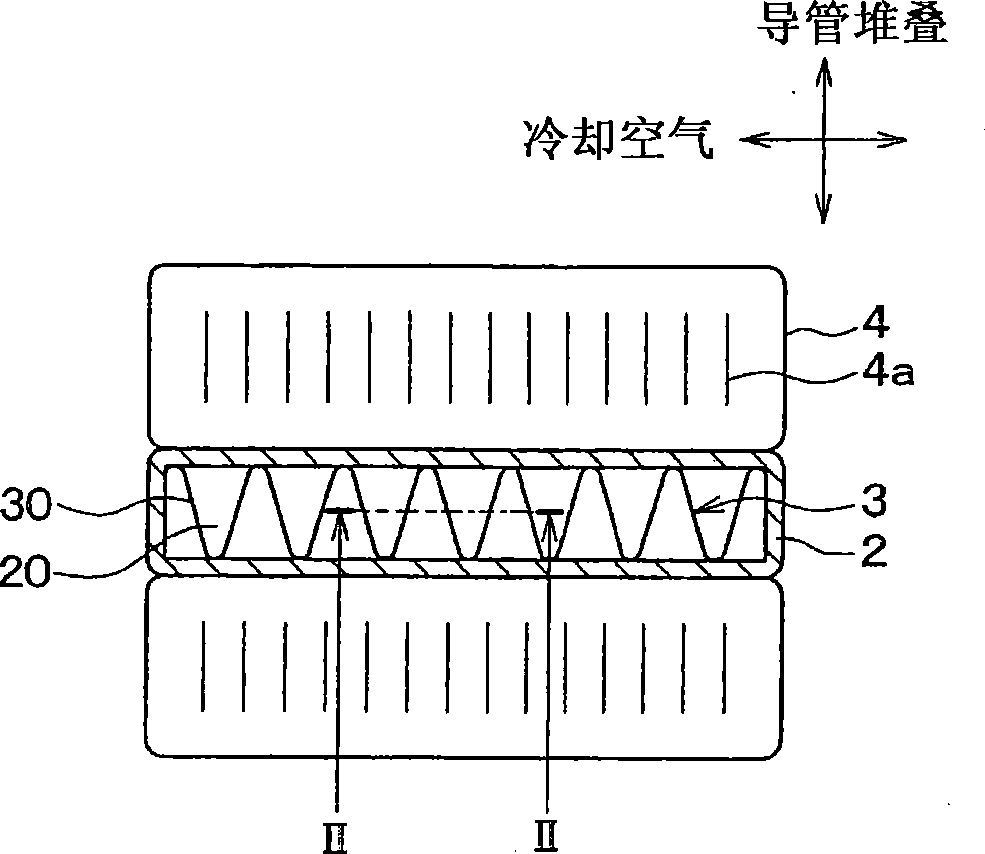

[0030] Such as figure 1 with figure 2 As shown, the core portion 1 of the intercooler includes: a plurality of stacked flat ducts 2, each duct having a flow channel formed inside to allow intake air to flow therethrough; inner fins 3, the inner fins 3 Located inside the flat ducts 2 ; outer fins 4 , each of which is located between stacked flat ducts 2 . The flat ducts 2 are stacked in the duct stacking directio...

no. 2 example

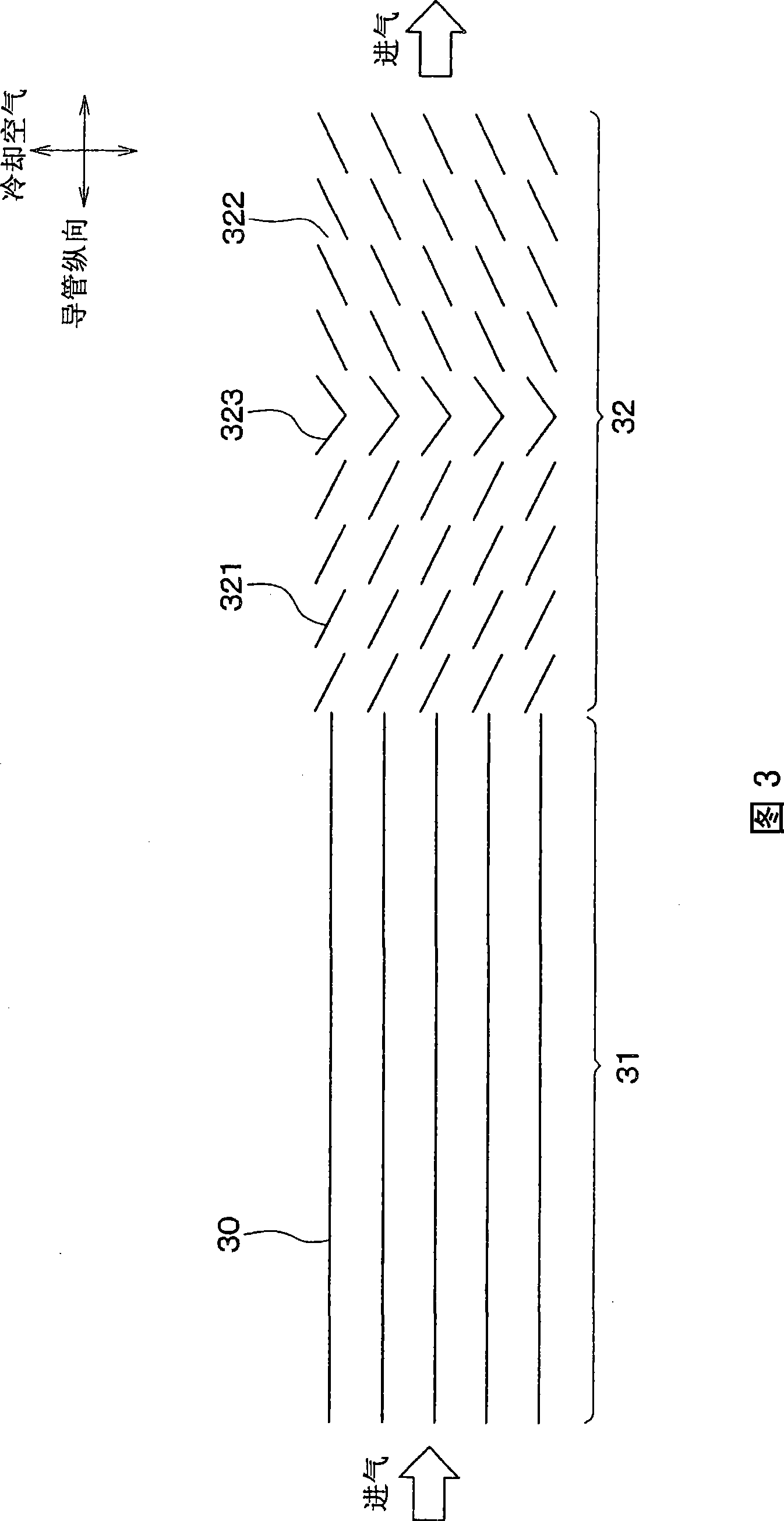

[0047] The second embodiment of the present invention will be shown in Fig. 5 and Figure 6 Based on this, the following description is made. The same components as those of the first embodiment are denoted by the same reference numerals, and descriptions thereof will be omitted below. Fig. 5 shows a cross-sectional view of the inner fin 3 of the second embodiment, when viewed from the stacking direction of the ducts 2 . FIG. 5 of the second embodiment is a view corresponding to FIG. 3 .

[0048] As shown in FIG. 5 , the inner fin 3 of this embodiment includes three different fin portions 31 - 33 . The three fin portions 31 to 33 , namely, the first fin portion 31 , the third fin portion 33 and the second fin portion 32 are successively arranged in the above order from the upstream side of the intake airflow. The first fin portion 31 is a straight fin, similar to the first embodiment. The second flap portion 32 is a strip flap, similar to the first embodiment.

[0049] ...

no. 3 example

[0054] A third embodiment of the present invention will be described below on the basis of FIG. 7 . The same components as those of the first embodiment are denoted by the same reference numerals, and descriptions thereof will be omitted below. Fig. 7 shows a cross-sectional view of the inner fin 3 of the third embodiment, when viewed from the stacking direction of the ducts 2 . The graph shown in FIG. 7 corresponds to the graph of FIG. 3 .

[0055] As shown in Fig. 7, the inner fin 3 of the present embodiment comprises a second two first fin parts 31 and a second fin part 32, and each of said first fin parts is similar to that of the first embodiment. straight fins, and the second fin part is a strip fin similar to the first embodiment. The two first fin portions 31 are arranged one after the other on the upstream side and the downstream side of the second fin portion 32 in the flow direction of the intake air. In other words, the second fin portion 32 is arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com