Three-cylinder dryer of dry-mixed mortar station

A three-cylinder dryer and dry-mixed mortar technology, which is applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problem of poor friction and wear performance between the drying cylinder and sand material, and poor rotation stability of the drying cylinder , Sand material flow is not smooth enough to achieve the effect of improving heat exchange performance, improving operation stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

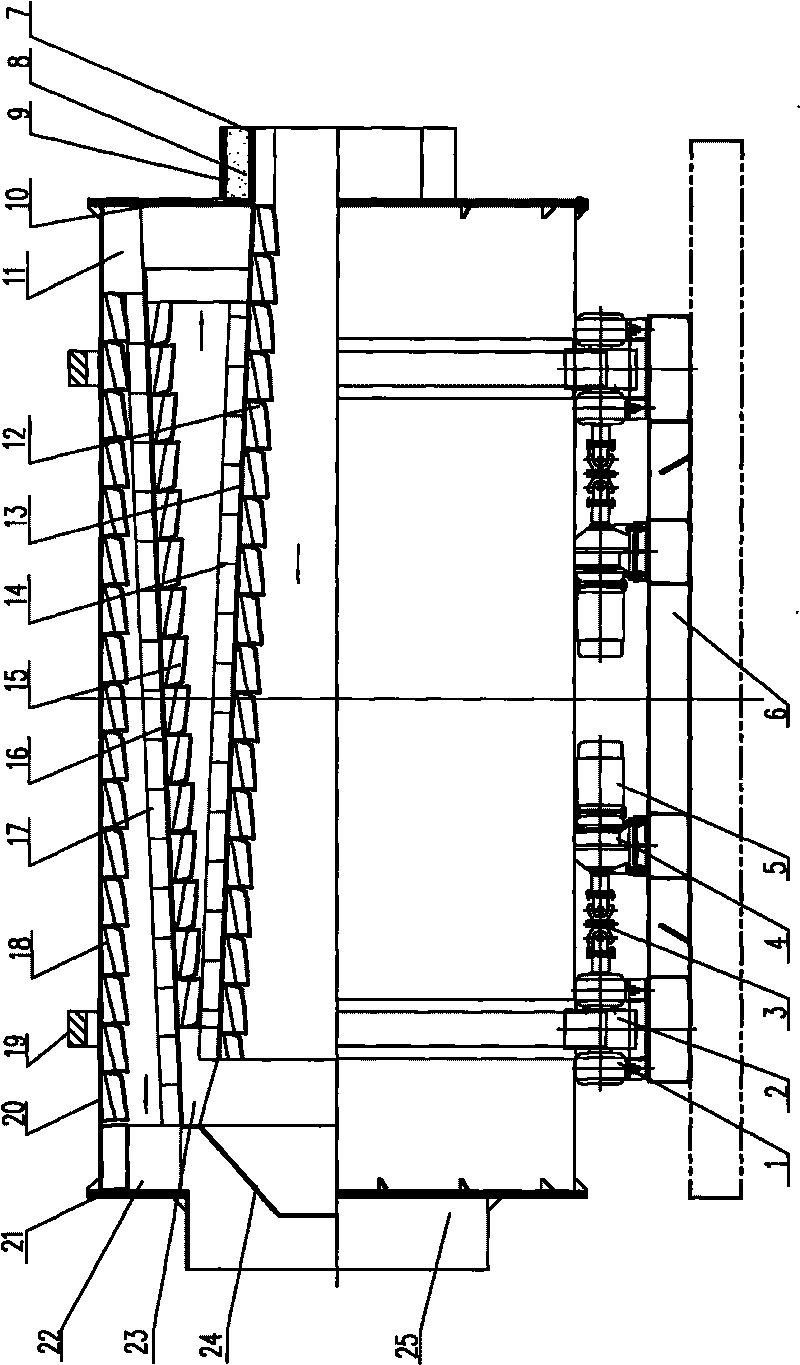

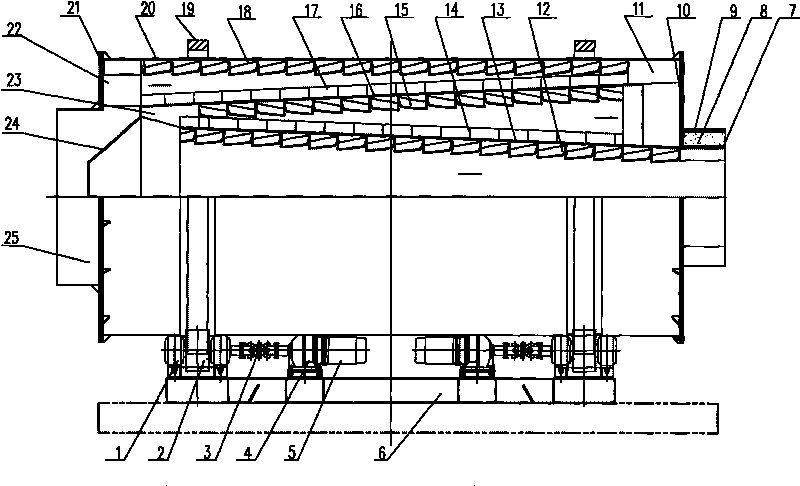

[0010] The dry-mixed mortar station three-cylinder dryer of the present invention is mainly composed of a feed pipe, a drying cylinder, a discharge pipe, and a rotary drive device. The feed pipe is a cylindrical structure, which is composed of an inner steel pipe 7, an aluminum silicate insulation layer 8 and an outer steel pipe 9. The inner steel pipe 7 and the outer steel pipe 9 are combined together, and the aluminum silicate insulation layer 8 is arranged between the inner and outer steel pipes. Those are fastened together and welded on the right end side plate 10 of the drying cylinder; the inner through hole centerline of the inner steel pipe 7 is the same axis as the rotation centerline of the drying cylinder. The drying cylinder includes an outer cylinder body 20, the two sides of the outer cylinder body 20 are connected with a feed pipe and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com