Evaporator and cabinet type air conditioner indoor machine employing same

A cabinet-type air conditioner and evaporator technology, applied in evaporator/condenser, air conditioning system, application, etc., can solve the problem of high cost of evaporator and achieve the effect of uniform heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

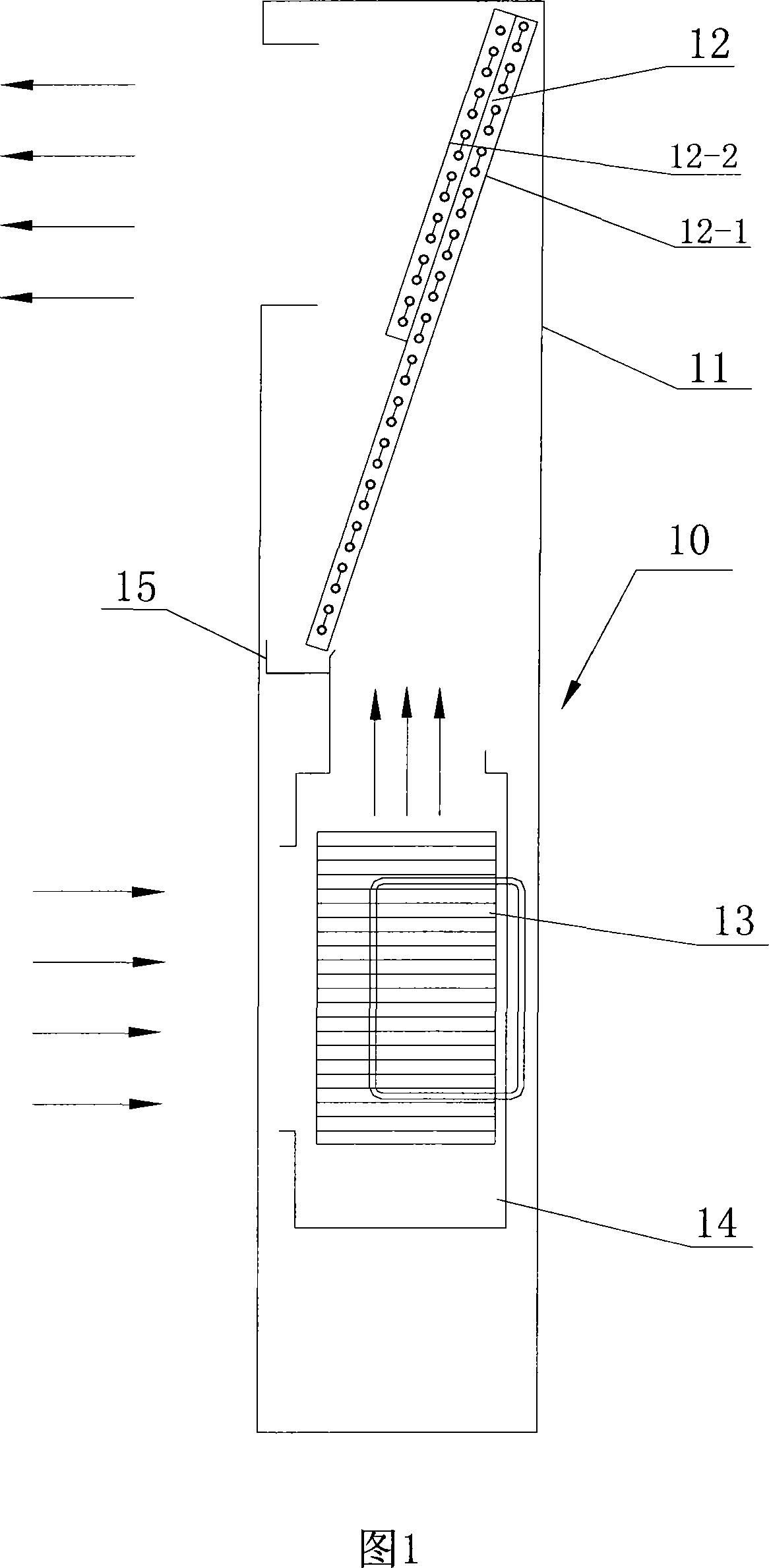

[0016] Embodiment 1, referring to Fig. 1 , an indoor unit 10 of a blower-type cabinet air conditioner includes an indoor unit casing 11, a centrifugal fan volute 14 is installed in the lower casing of the indoor unit, and a centrifugal fan volute 14 is installed in the centrifugal fan volute 14. The centrifugal fan 13 is equipped with an evaporator 12 above the centrifugal fan, which includes a windward side evaporator 12-1 and a leeward side evaporator 12-2, and a water receiving tray 15 at the lower end of the evaporator 12.

[0017] After the external wind enters the interior of the indoor unit casing, it blows to the evaporator 12 through the centrifugal fan 13. The evaporators 12-1 on the windward side form a whole row, and the evaporators 12-2 on the leeward side are arranged on the upper part of the evaporator 12, and its height is Half of the windward side evaporator 12-1. This makes the upper part of the evaporator 12 a double row, and the lower part of the evaporator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com