Heat exchanger having different flowing paths

a technology of heat exchanger and flowing path, which is applied in the field of heat exchanger, can solve the problems of not being able to facilitate the heat exchange effect, and achieve the effect of facilitating the heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

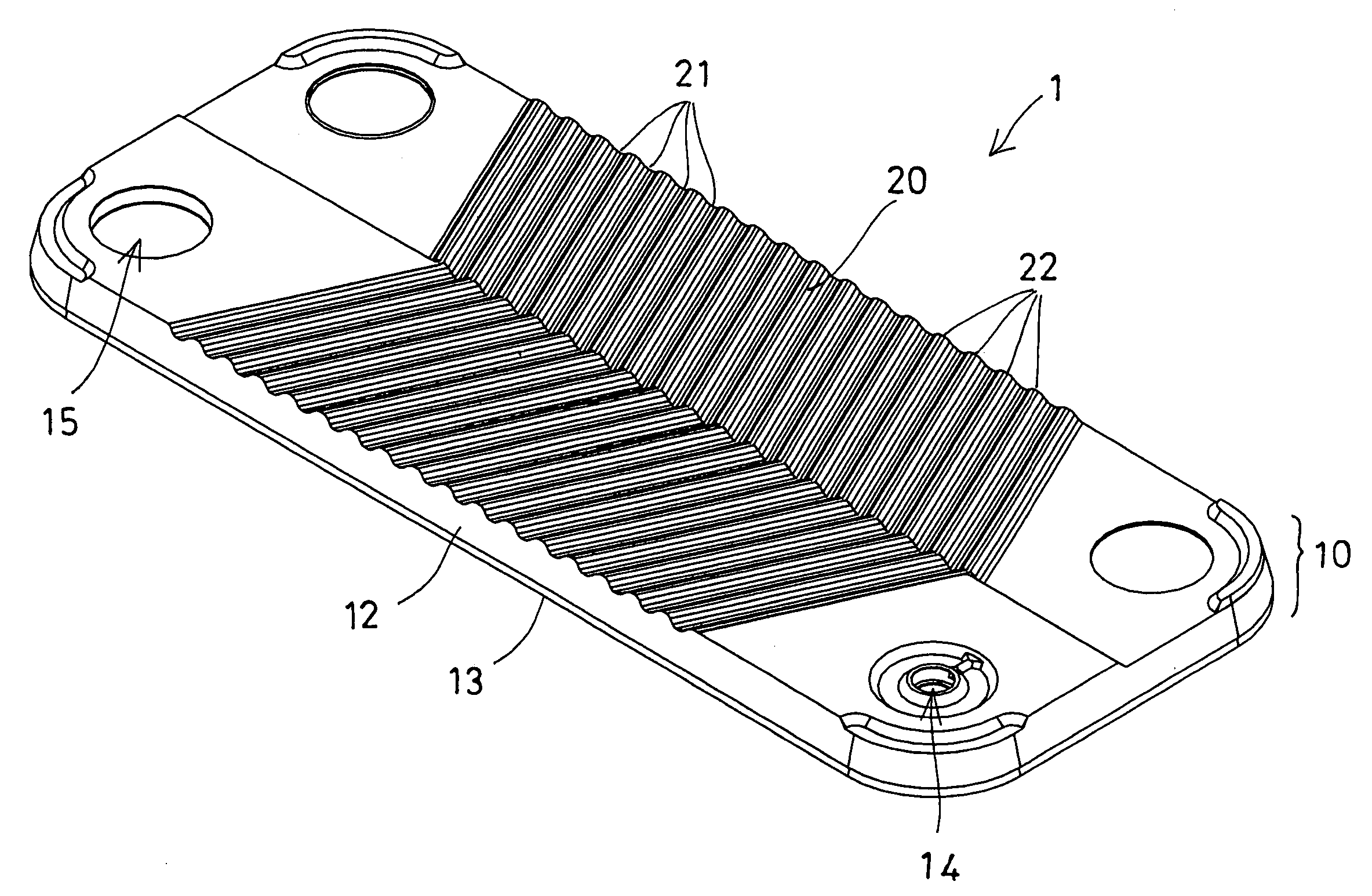

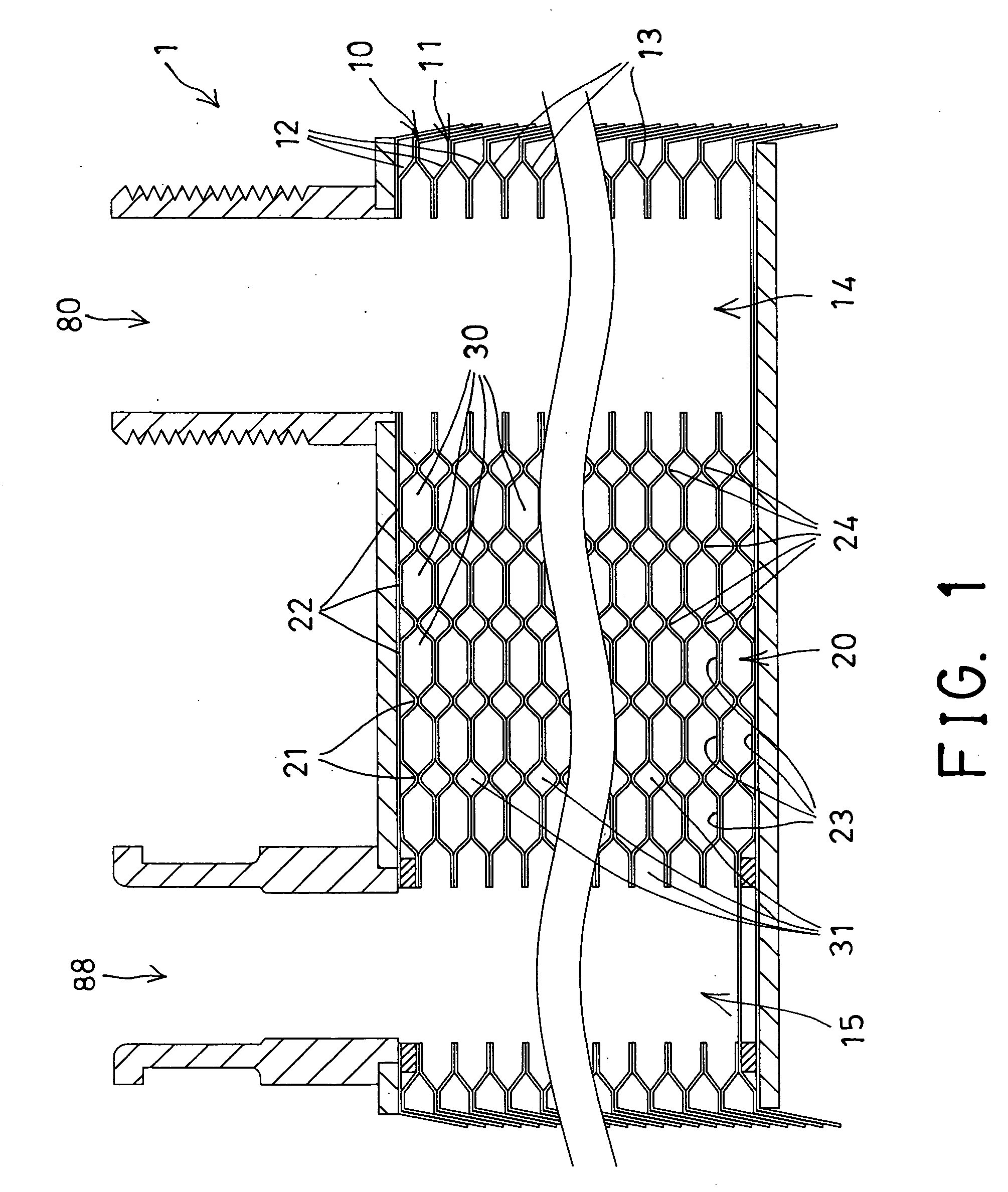

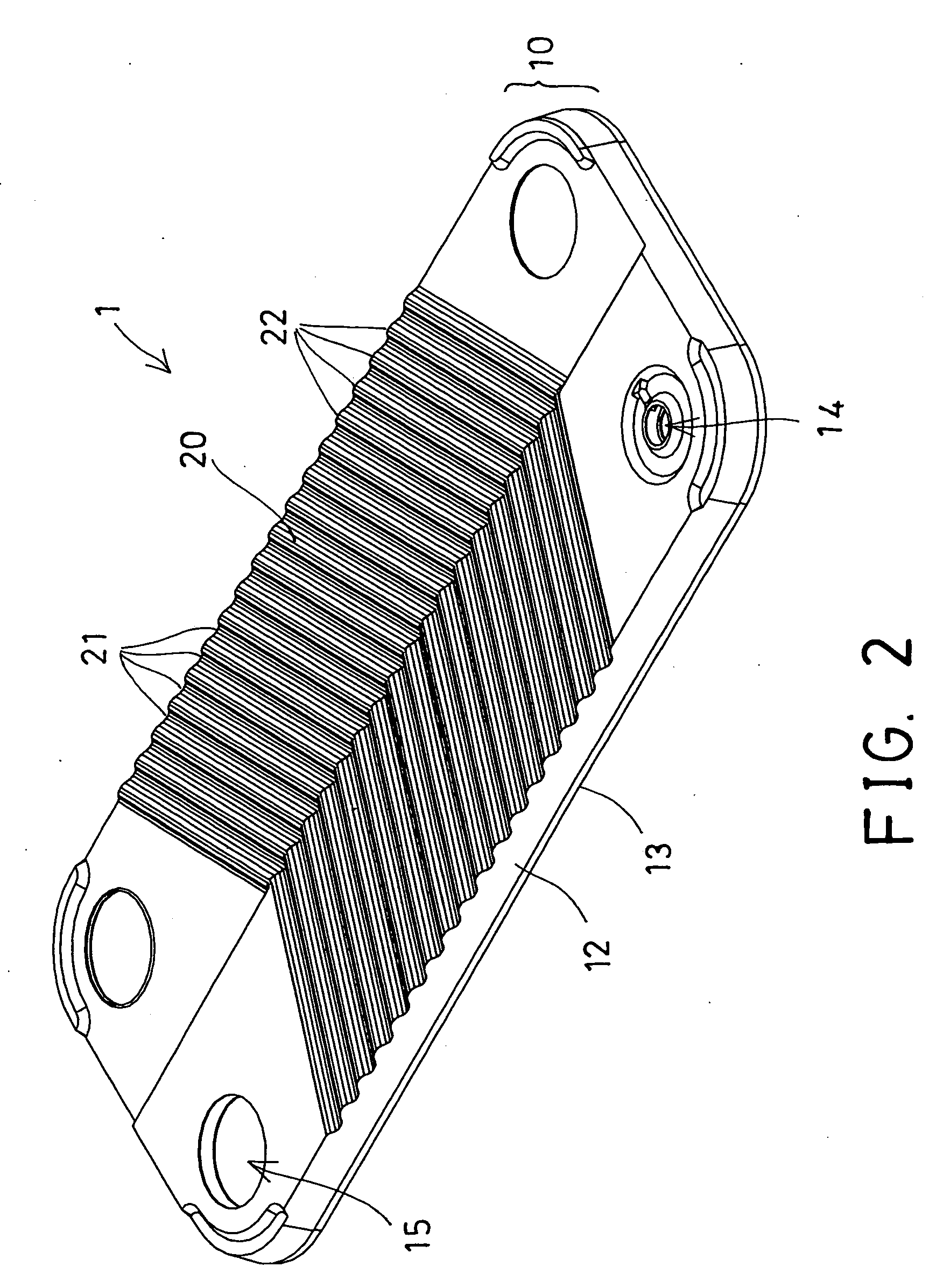

[0018] Referring to the drawings, and initially to FIGS. 1-2, a heat exchanger 1 in accordance with the present invention comprises one or more heat exchanging assemblies or plate sets 10, 11 alternatively superposed with each other and each including two heat exchanging boards or plates 12, 13 disposed and superposed with each other for allowing the upper or first plate 12 to be disposed above the lower or second plate 13 which is disposed above the upper or first plate 12 of the other or lower plate set 11. The plates 12-13 each include a wavy structure 20 arranged to allow the heat medium or water or fluid to flow through the wavy boards or plates 12-13 with an increased contacting area, and to allow the heat medium or water or fluid to be heat exchanged with the other heat medium, such as ambient air, other heat media or water or fluid or the like.

[0019] The formation or the provision of the wavy structure 20 of the boards or plates 12-13 is provided for increasing the contacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com