Strong convection structure on heat treatment furnace

A heat treatment furnace and strong convection technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of low yield of broken bonds, complicated mechanism and operation process, and unreachable heat exchange area, etc., to increase the heat exchange area , good heat exchange effect, uniform high-speed flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

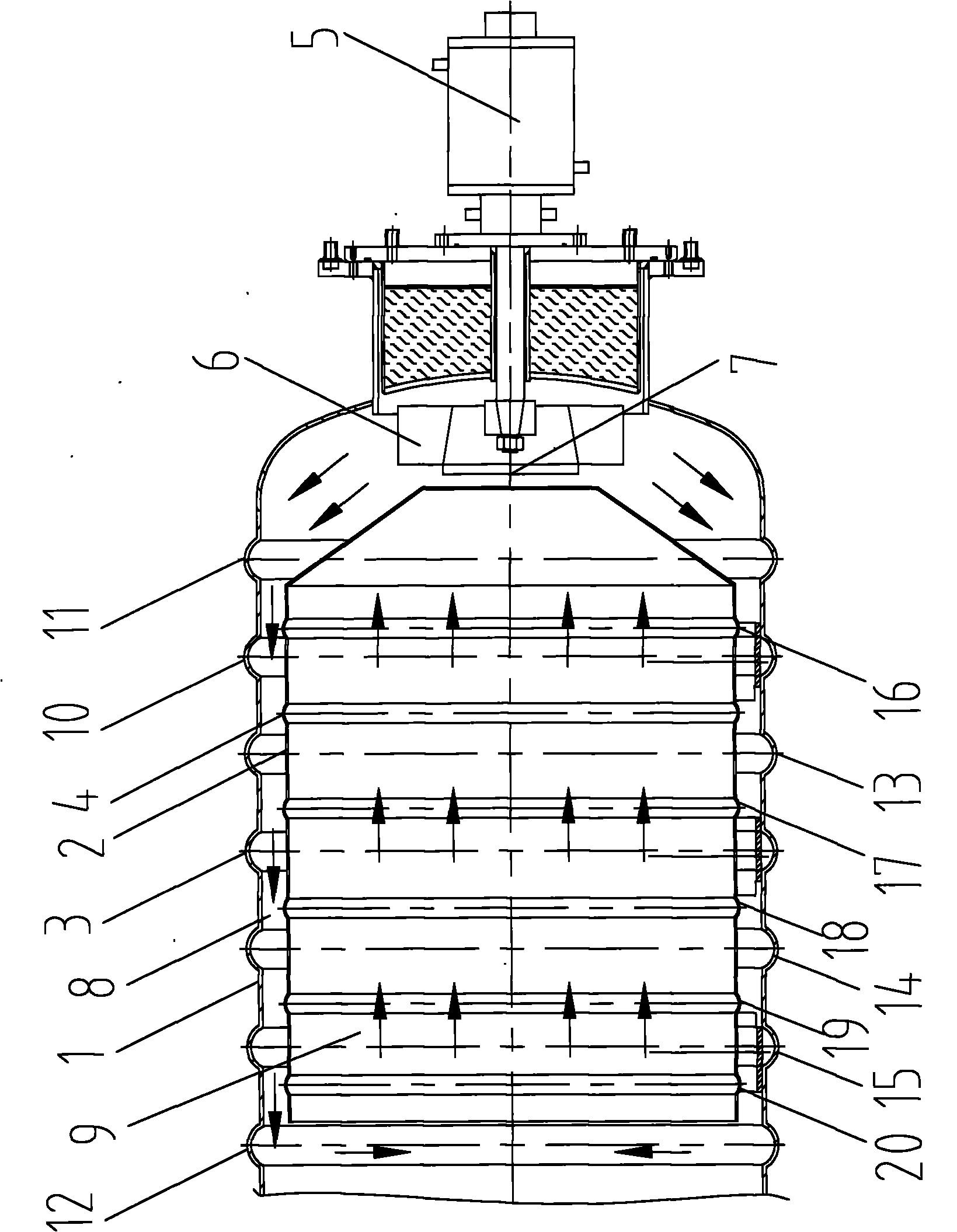

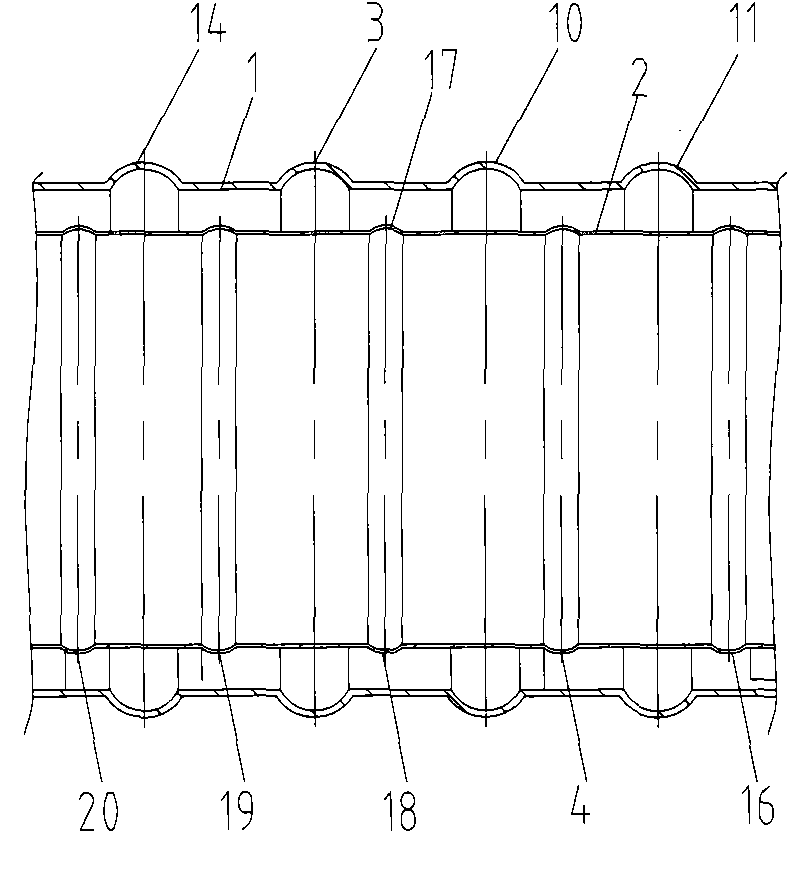

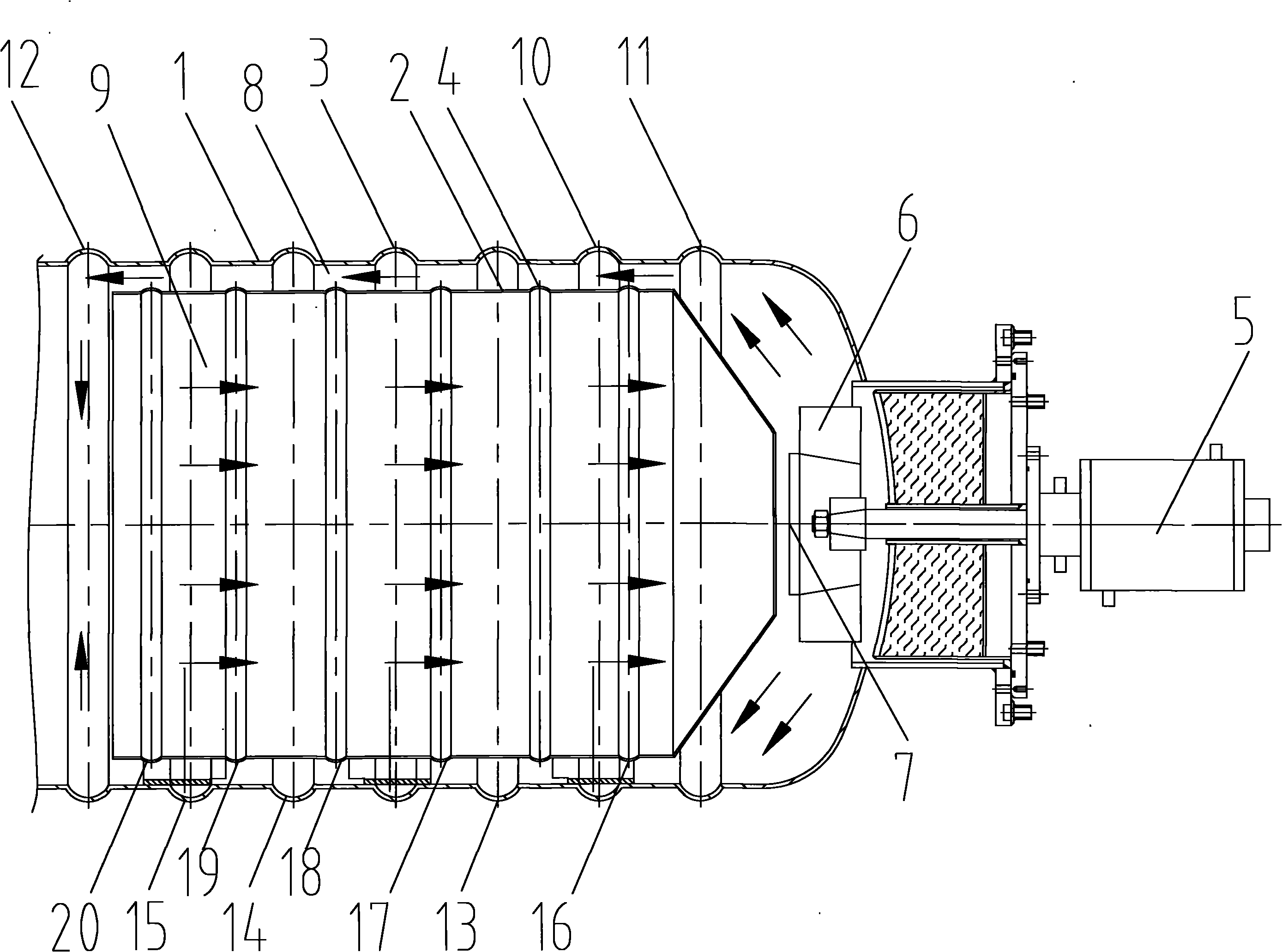

[0010] see figure 1 As shown, the interior of the furnace 1 with an inner cavity is provided with an air guide tube 2 with an inlet at the other end and an outlet at the other end, and the blades 6 of the centrifugal fan 5 are sealed in the furnace 1 through the furnace 1 mouth, and the furnace 1. The air guide tube 2 and the centrifugal fan 5 are coaxially designed. The inner peripheral surface of the furnace 1 is extruded outward to form a plurality of annular grooves 3, 10, 11, which are arranged at intervals along the axial direction on the inner surface. 12, 13, 14, 15, the inner peripheral surface of the guide tube 2 is extruded outward to form a plurality of annular protrusions arranged at intervals on the outer surface 4, 16, 17, 18, 19, 20, the outlet of the guide tube 2 Aiming at the axial suction port 7 of the centrifugal fan 5, an air supply channel 8 communicating with the inlet is formed between the furnace liner 1 and the guide tube 2, and a return channel conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com