Thermal mechanical fatigue test system and method for performing hollow turbine blade superposed high-cycle vibration

A technology of thermomechanical fatigue and turbine blades, which is applied to the thermomechanical fatigue test system and field of hollow turbine blades with superimposed high-cycle vibration, can solve the problems of inability to adjust the stress distribution of the blade body, the inability to adjust the stress state of the turbine blades, and the inability to achieve turbine Blade thermomechanical fatigue test and other issues, to ensure the safety and accuracy of testing the life of turbine blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

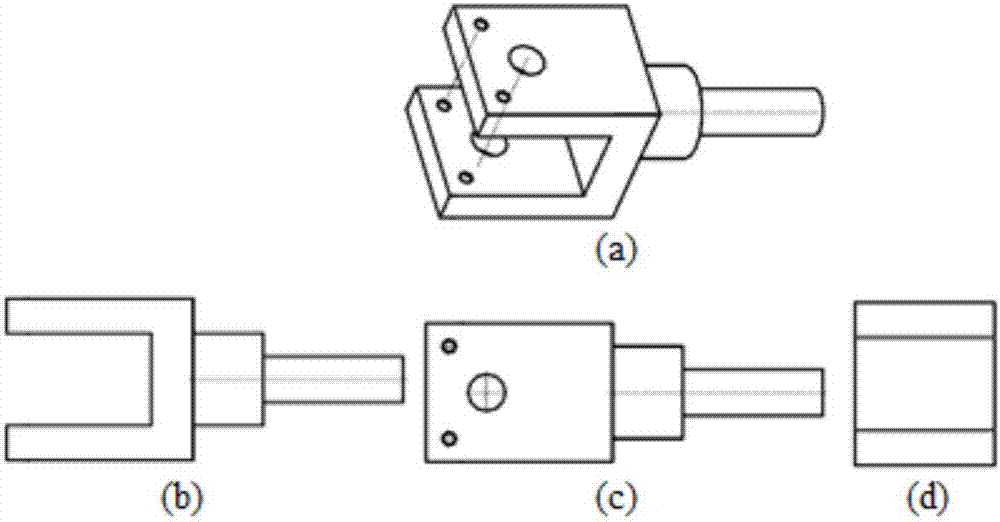

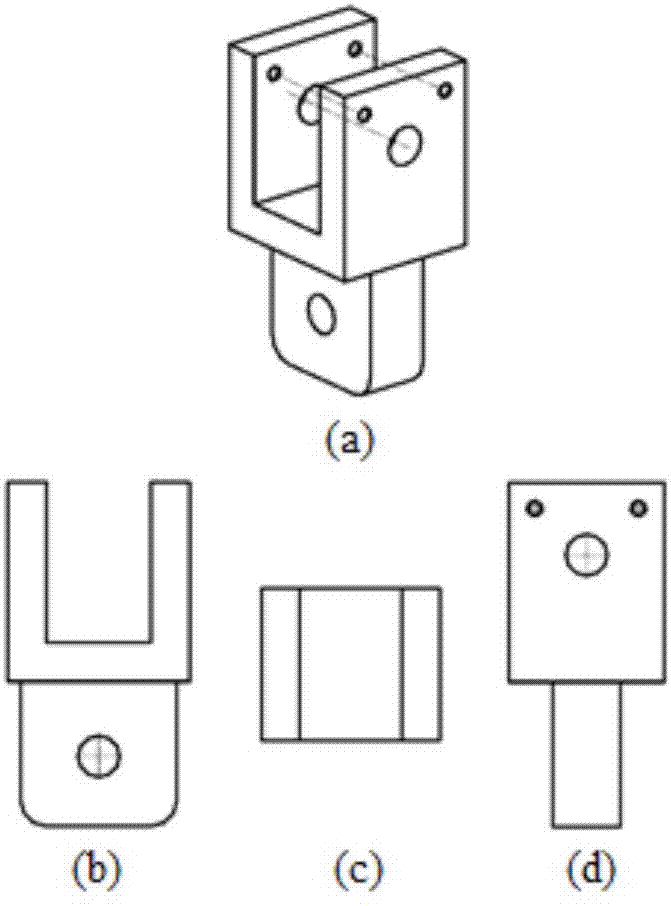

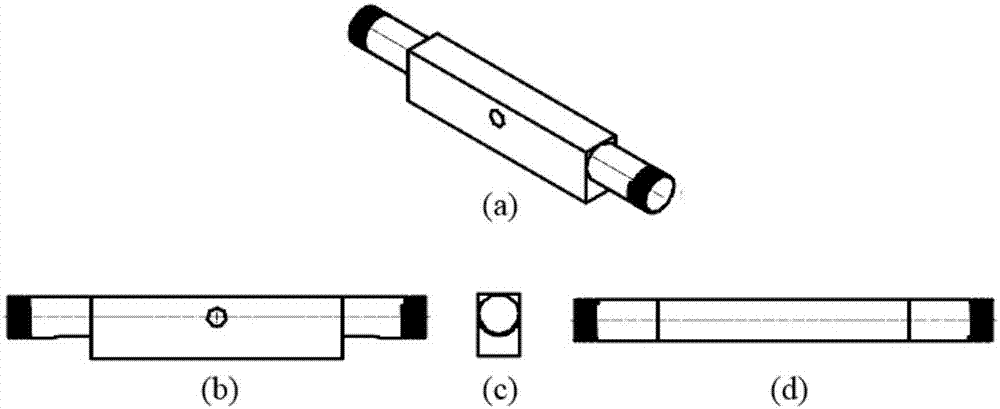

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] The present invention is mainly aimed at the thermomechanical fatigue test system of superimposed high-cycle vibration of hollow turbine blades, wherein high and low cycle loads are terms in the industry, and low cycle loads are generally large-scale low-frequency loads (amplitude is generally greater than 5kN, and frequency is generally less than 1Hz ), the high-cycle load is generally a small-amplitude high-frequency load (the displacement amplitude is generally less than 1.5mm, and the frequency is generally greater than 10Hz).

[0041] like Figure 16 As shown, the system of the present invention includes five parts: high cycle load loading subsystem, low cycle load loading subsystem, temperature load loading subsystem, cooling subsystem and load coordination control subsystem. The high-cycle load loading subsystem and the low-cycle load l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com