Fluid agitating fin, method of fabricating the same and heat exchanger tube and heat exchanger or heat exchanging type gas cooling apparatus inwardly mounted with the fin

a technology of agitating fins and fins, which is applied in the direction of lighting and heating apparatus, machines/engines, laminated elements, etc., can solve the problems of insufficient function and achieve the effect of effective agitation, excellent cooling efficiency and efficient promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

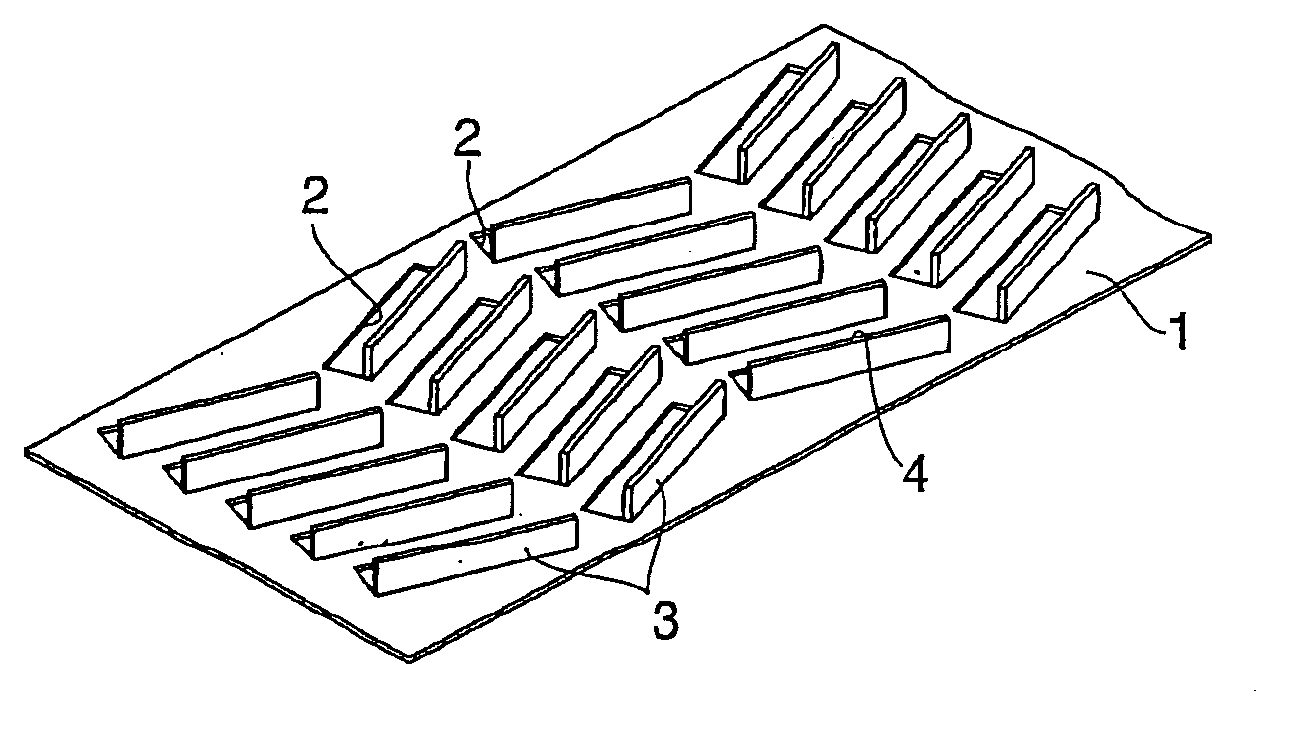

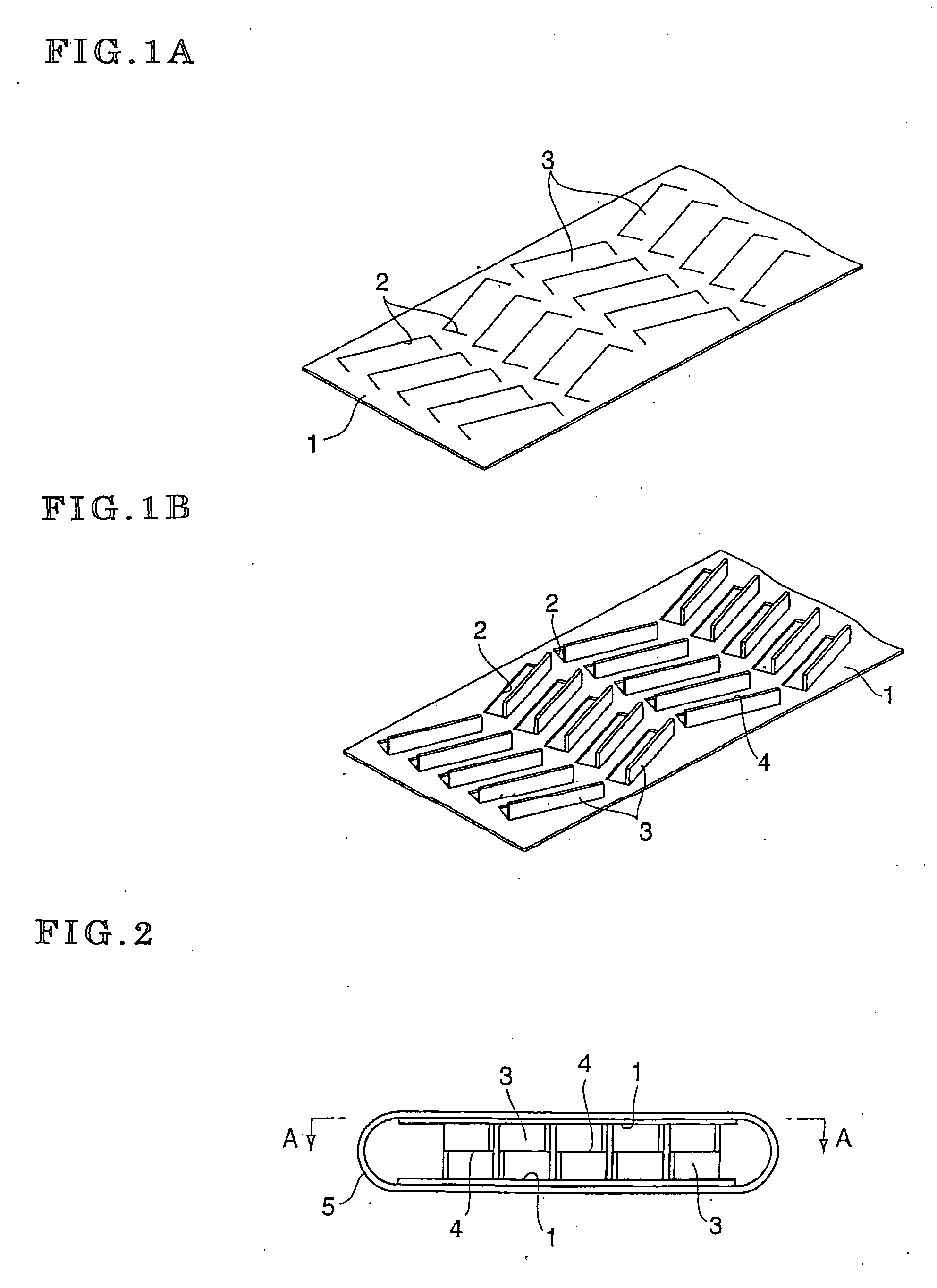

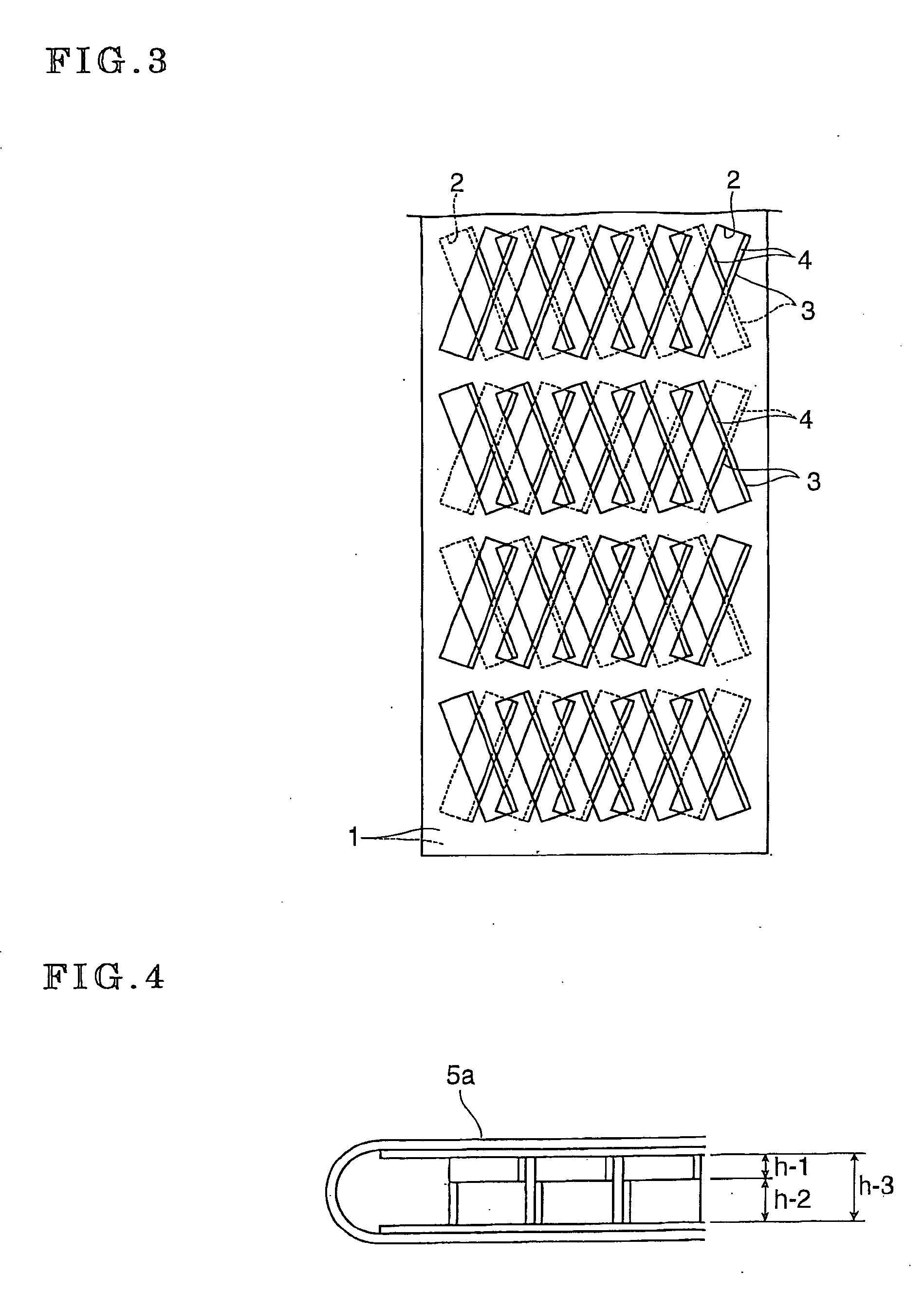

[0046] According to a fluid agitating plate fin 3 according to a first embodiment of the invention, as shown by FIG. 1, thin plates comprising austenite species stainless steel of SUS 304, SUS 316 or the like having a thickness of about 0.1 through 0.5 mm are worked in a rectangular shape having a predetermined dimension to provide a plurality of plate materials, two sheets of the plate materials are pressed to form a plurality of notched portion 2 substantially in a channel-like shape having a predetermined dimension directions of which alternately differ as shown by FIG. 1A. Next, remaining notched portions of the notched portion 2 are cut to be raised to be orthogonal to a surface of the plate member to provide a plate 1 formed with fluid agitating plate fins 3 directions of which differ alternately at respective rows and blade edge 4 of which are constituted by linear lines inclined to a longitudinal direction. Thereafter, by preparing two sheets of the provided plates 1 and but...

embodiment 2

[0048] There is provided a fluid agitating plate fin 3a as shown by FIG. 5B similar to embodiment 1 except that a plate material constituted by connecting two sheets of the plate materials in Embodiment 1 in a longitudinal direction is prepared, predetermined notched portions are provided at plate materials on the left and on the right of a boundary of a center folding portion 1a-3, a fluid agitating fin 3a as shown by FIG. 5A is formed after raising remaining notched portions of the outer notched portions, thereafter, the plate material is folded at the center folding portions 1a-3, and respective blade edges 4a of the fluid agitating fins 3a formed at a plate 1 (1a-1) and a plate 2 (1a-2) are butted to be opposed to each other, a heat exchanger tube inwardly mounted with the plate fin 3a is finished similar to Embodiment 1 to be subjected to a cooling test by an EGR gas cooling apparatus (shell and tubes type heat exchanger) similar to Embodiment 1, as a result, it is confirmed th...

embodiment 3

[0049] A fluid agitating plate fin 3b is provided similar to Embodiment 1 except that a shape of the fluid agitating plate fin formed to a plate material is formed by bending a shape of a blade edge 4b in a longitudinal direction in place of the fluid agitating plate fins 3 and 3a provided by Embodiment 1 or Embodiment 2, and when a heat exchanger tube inwardly mounted with the fluid agitating fin 3b is constituted by using the fin 3b and is mounted to an EGR gas cooling apparatus to be subjected to a cooling test similar to Embodiment 1, it is confirmed that a cooling efficiency is further increased in comparison with that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com