Rumen bypass glucose microcapsule and preparation method thereof

A glucose and rumen-passing technology, which is applied in the application field of dairy cattle feed additives in the postpartum period, can solve problems such as low stability, incomplete coating, and poor rumen effect, and achieve the effect of reducing degradation rate and increasing milk production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

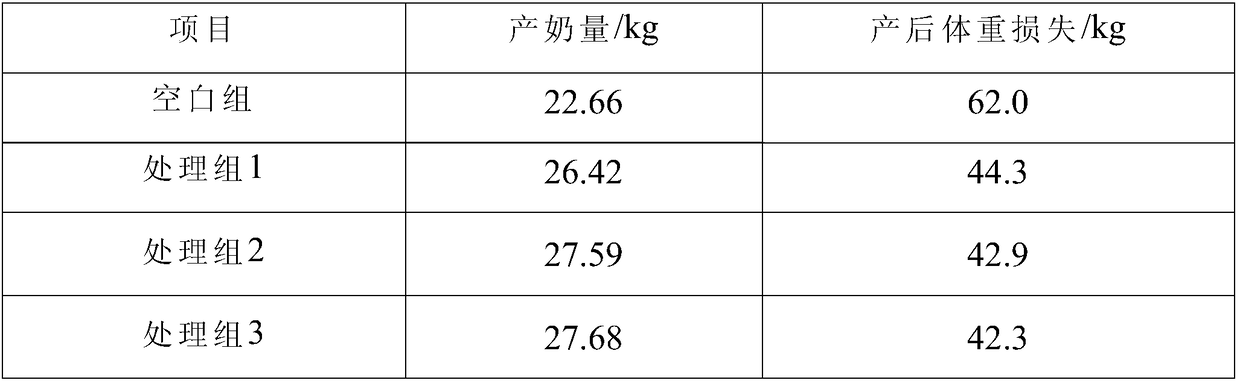

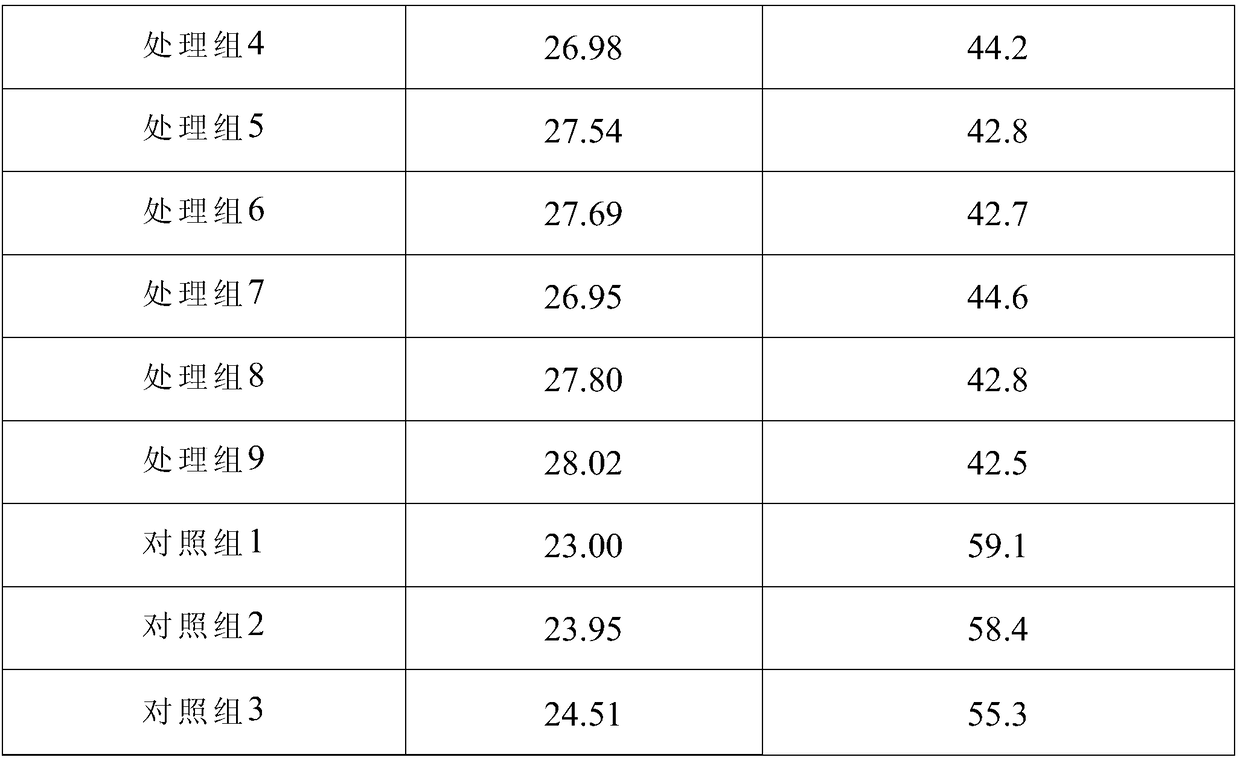

Examples

Embodiment 1

[0018] A rumen-passing glucose microcapsule, the preparation process of which is as follows:

[0019] (1) Glucose is made into pellets, dried at a temperature of 40° C. for 20 minutes to obtain pellets with a diameter of 10 mm;

[0020] (2) Put the dried glucose pellets into the fluidized bed, raise the temperature of the fluidized bed to 40°C, and preheat for 20 minutes;

[0021] (3) Chitosan wall material is dissolved in the sodium chloride aqueous solution of mass concentration 5%, and the obtained concentration is the chitosan wall material solution of 15%, and the polyacrylic resin wall material is dissolved in the mass concentration that is 70% In the ethanol solution, the polyacrylic acid resin wall material solution that the obtained concentration is 20%;

[0022] (4) atomize the chitosan prepared by step (3) and the polyacrylic acid resin wall material solution and spray successively on the surface of the glucose pellets in the fluidized bed, and the fluidized bed co...

Embodiment 2

[0024] A rumen-passing glucose microcapsule, the preparation process of which is as follows:

[0025] (1) Glucose is made into pellets, dried at a temperature of 60° C. for 20 minutes to make pellets with a diameter of 10 mm;

[0026] (2) Put the dried glucose pellets into the fluidized bed, raise the temperature of the fluidized bed to 45°C, and preheat for 15 minutes;

[0027] (3) chitosan wall material is dissolved in the sodium chloride aqueous solution of mass concentration 3%, the chitosan wall material solution that makes concentration is 10%, polyacrylic acid resin wall material is dissolved in mass concentration and is 70% In ethanol solution, the polyacrylic acid resin wall material solution that makes concentration is 15%;

[0028] (4) atomize the chitosan prepared by step (3) and the polyacrylic acid resin wall material solution and spray successively on the surface of the glucose pellets in the fluidized bed, and the fluidized bed coating process parameter is tha...

Embodiment 3

[0030] A rumen-passing glucose microcapsule, the preparation process of which is as follows:

[0031] (1) Glucose is made into pellets, dried at a temperature of 60° C. for 20 minutes, and made into pellets with a diameter of 5 mm;

[0032] (2) Put the dried glucose pellets into the fluidized bed, raise the temperature of the fluidized bed to 50°C, and preheat for 10 minutes;

[0033] (3) chitosan wall material is dissolved in the sodium chloride aqueous solution of mass concentration 3%, the chitosan wall material solution that makes concentration is 10%, polyacrylic acid resin wall material is dissolved in mass concentration and is 80% In ethanol solution, the polyacrylic acid resin wall material solution that makes concentration is 15%;

[0034] (4) atomize the chitosan prepared by step (3) and the polyacrylic acid resin wall material solution and spray successively on the surface of the glucose pellets in the fluidized bed, and the fluidized bed coating process parameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com