Metal sulfide ore all-oxygen negative-energy pyrogenic smelting method

A technology of pyrometallurgy and sulfide ore, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve problems such as high production costs, environmental pollution, and large fuel consumption, and achieve the goal of reducing pollution, reducing costs, and increasing SO2 concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

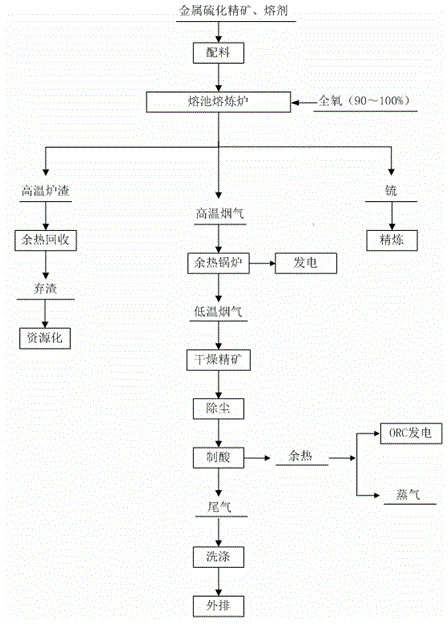

[0021] like figure 1 As shown, the general smelting and processing factory of Yunnan Copper Industry Group uses the Isa furnace to smelt copper sulfide ore. Copper sulfide concentrate is made into ore powder, which is mixed with metallurgical flux quicklime, and the addition amount is 5% of the mass of copper sulfide concentrate, and the mixed material of copper sulfide concentrate with a copper grade of 48% is added to the Aisa furnace through the feeding port for smelting. The smelting time is 1.5h. When feeding materials, ensure that the temperature in the furnace is 1200°C, and the controllable temperature should be kept at 1250-1350°C. During the oxidation blowing process, the spray gun is inserted into the furnace from the top or side of the furnace, and the total oxygen with a concentration of 96% enters quickly through the spray gun. Into the liquid layer below the slag surface, the melt in the molten pool is strongly stirred, so that the material reacts with oxygen t...

Embodiment 2

[0023] like figure 1 As shown, the Yunnan Copper Industry Group Chuxiong Dianzhong Nonferrous Metals Company uses the Isa furnace to smelt copper sulfide ore. Copper sulfide concentrate is made into ore powder, which is mixed with quicklime, a metallurgical flux, in an amount of 8% of the mass of copper sulfide concentrate, and the mixture of copper sulfide concentrate with a copper grade of 41% is added to the Aisa furnace through the feeding port for smelting. The smelting time is 2h. When feeding materials, ensure that the temperature in the furnace is 1200 ° C, and the controllable temperature should be kept at 1250 ~ 1350 ° C. During the oxidation blowing process, the spray gun is inserted into the furnace from the top or side of the furnace, and the total oxygen with a concentration of 92% enters quickly through the spray gun. Into the liquid layer below the slag surface, the melt in the molten pool is strongly stirred, so that the material reacts with oxygen to melt an...

Embodiment 3

[0025] like figure 1 As shown, the first smelter of Yunnan Tin Industry Group uses Osmelt furnace to smelt tin sulfide ore. The tin sulfide ore is beneficiated to obtain tin sulfide concentrate, and the tin sulfide concentrate is mixed with quicklime with a mass of 6% tin sulfide concentrate, and the tin sulfide-tin concentrate mixture material with a tin grade of 45% is added to Austria from the feeding port. The smelting is carried out in the Smart Furnace, and the smelting time is 3 hours. When feeding materials, it is necessary to ensure that there is a sufficiently high temperature in the furnace of 1150°C, and the controllable initial temperature should be kept at 1200-1300°C. During the oxidation blowing process, the spray gun is inserted into the furnace from the top or side of the furnace, and the total oxygen with a concentration of 94% passes through The spray gun quickly enters into the liquid layer below the slag surface, and has a strong stirring effect on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com