Evaporator and heat exchanger with external loop, as well as heat pump system and air conditioning system comprising said evaporator or heat exchanger

一种热交换器、外部回路的技术,应用在装备排泄装置的蒸发器,冷凝器领域,能够解决不均匀流动、降低效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

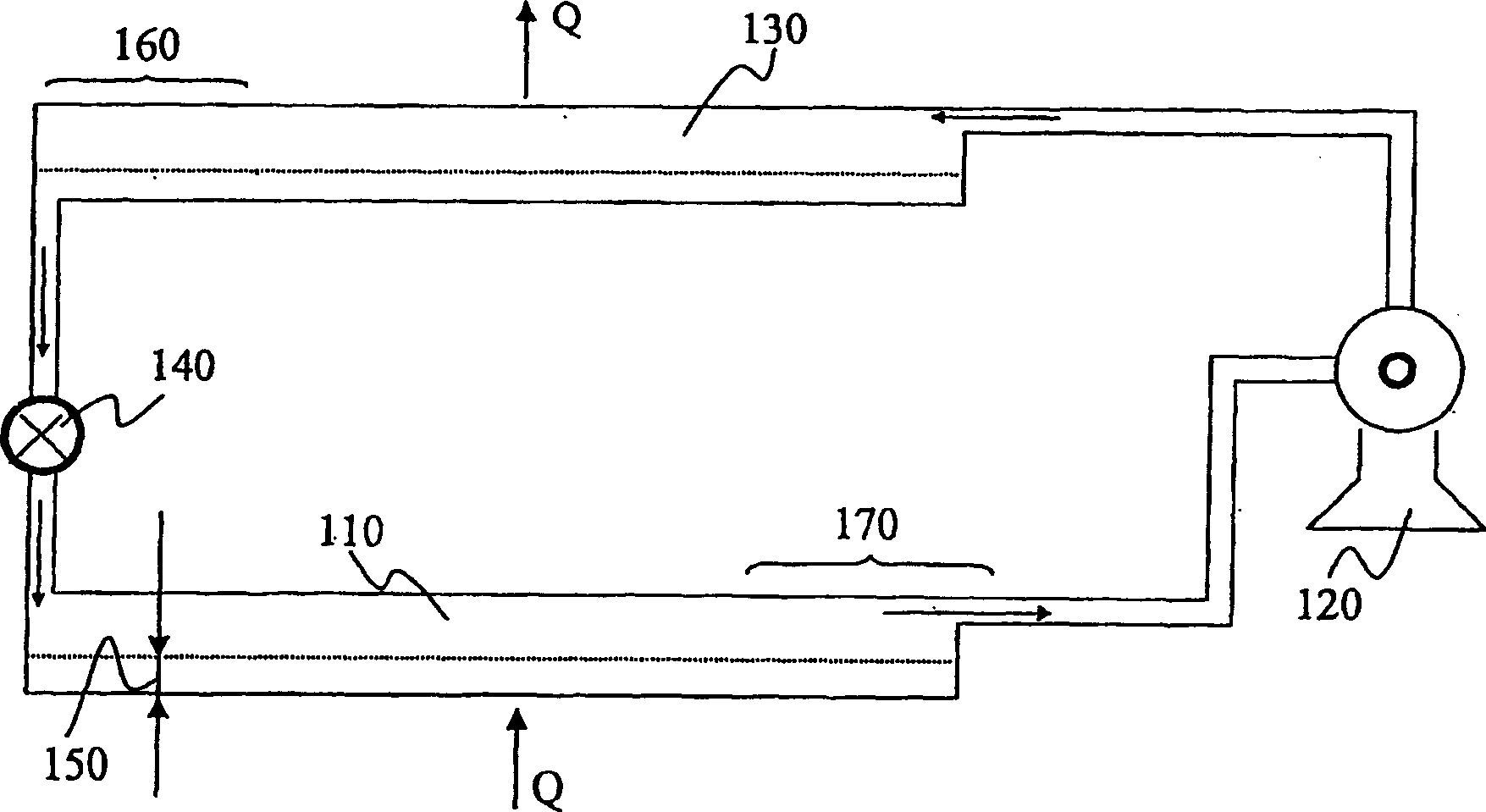

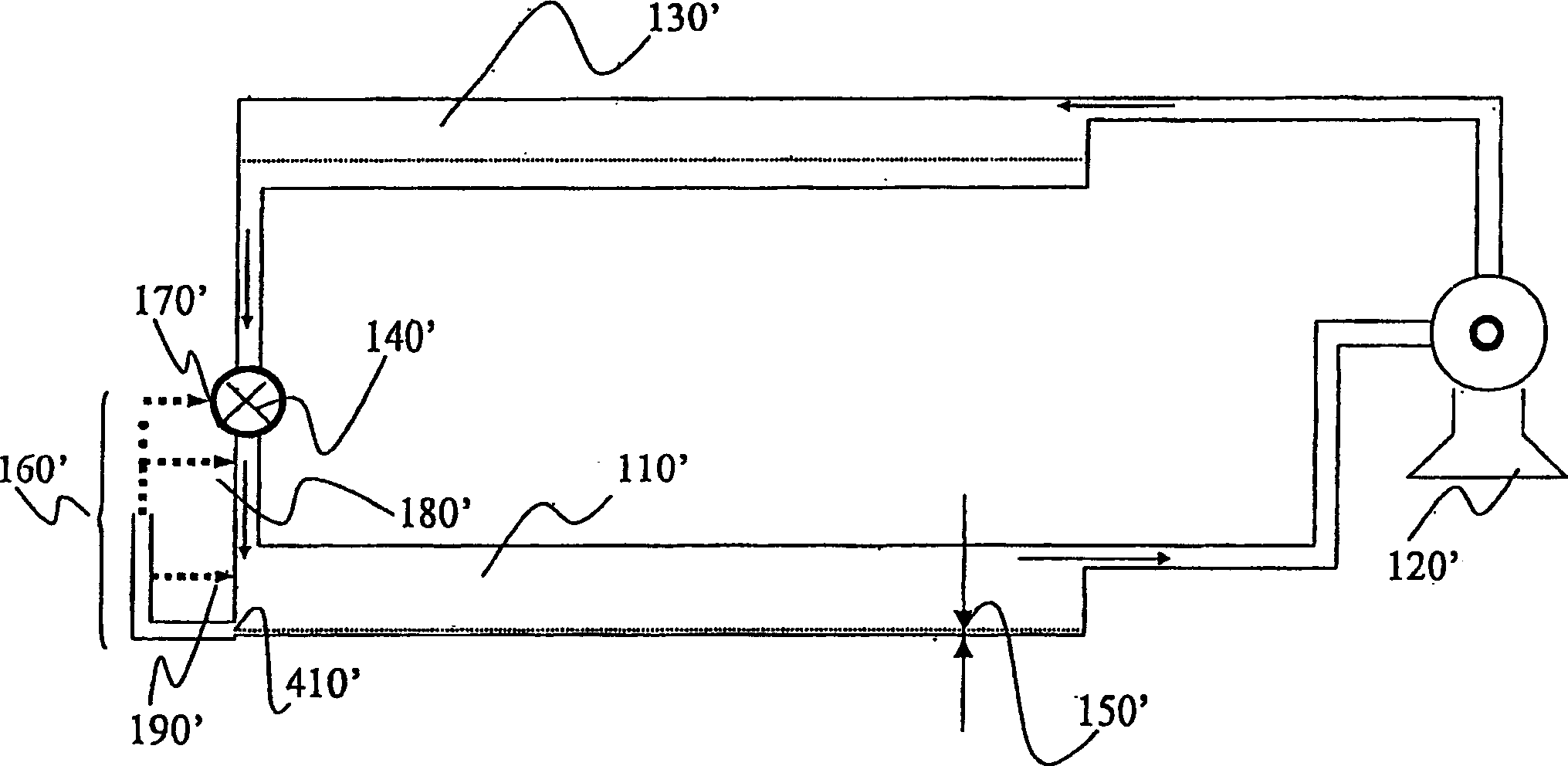

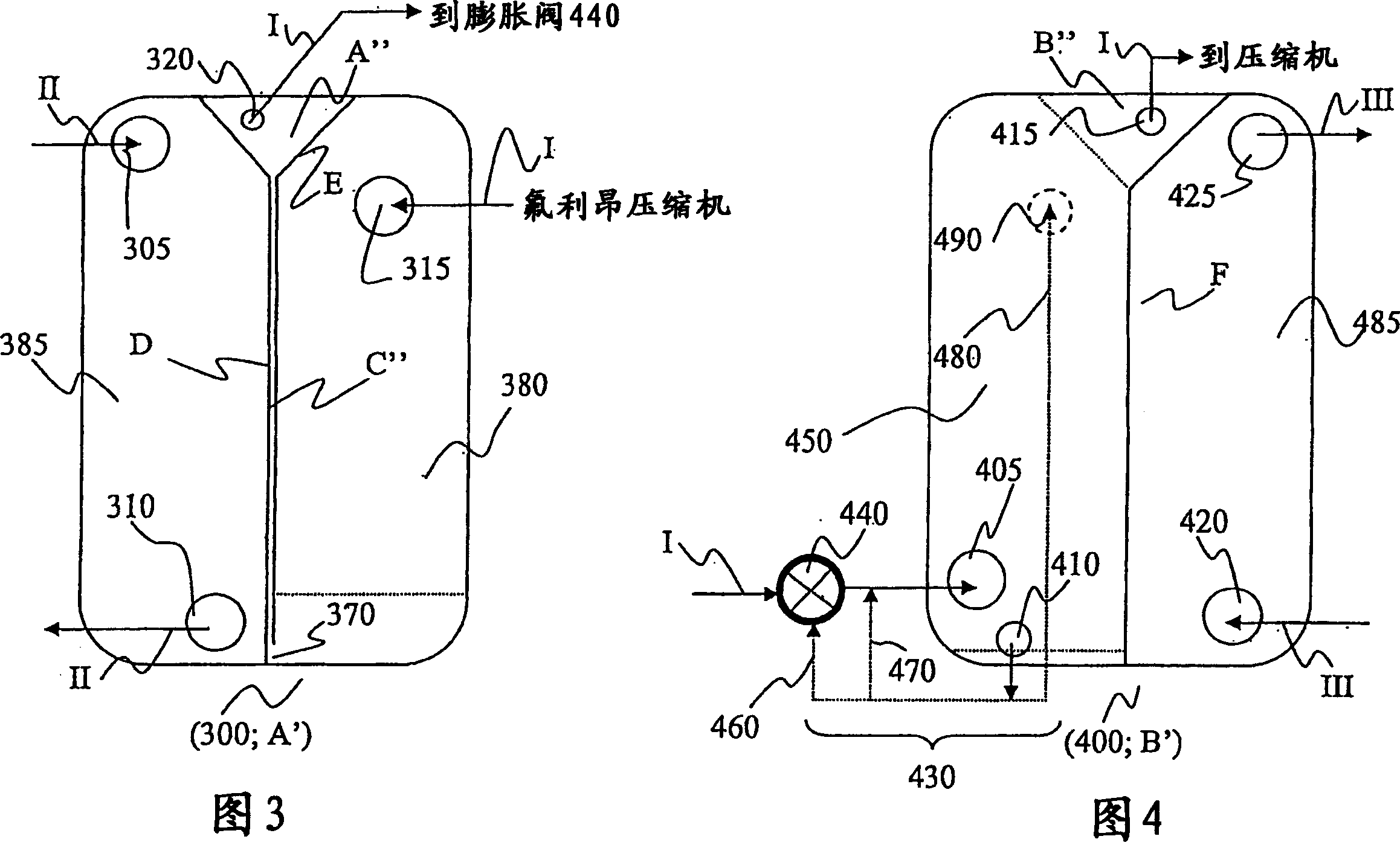

[0019] A problem with evaporator efficiency is that ideally no liquid should leave the evaporator, that is to say the liquid content of the evaporated medium should be zero, which is difficult to achieve in practice. It is thus an object of the present invention to provide a more efficient evaporator by minimizing the liquid content of the evaporated medium leaving the evaporator.

[0020] Another problem is that the higher liquid content of the evaporated medium increases the wear of the cooperating compressors connected to the evaporator. Thus, another object of the present invention is to reduce the wear of the compressor connected to the evaporator by minimizing the liquid content of the evaporated medium leaving the evaporator.

[0021] A specific problem with plate heat exchangers is that the accumulation of liquid medium in the lower part of the evaporator can cause uneven flow and consequently reduce efficiency. It is thus an object of the present invention to increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com