Coal chemical salt-containing wastewater treatment system and method

A technology for salty wastewater and coal chemical industry. It is applied in the directions of oxidized water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of high energy consumption and poor environmental protection, and achieve rapid concentration and harmlessness. and the effect of resource disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

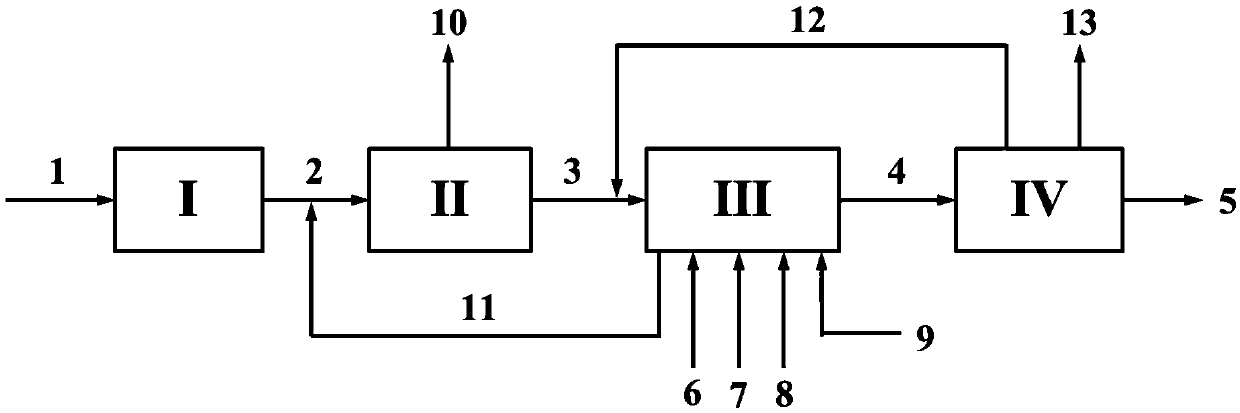

[0063] The saline wastewater A used in this example comes from the coal chemical process. The total solids dissolved in the saline wastewater A has a TDS of 4500 mg / L and a COD of 125 mg / L.

[0064] The saline wastewater A enters the pretreatment unit for treatment, removes the interfering substances in the saline wastewater through biological treatment and filtration, and obtains the pretreated saline wastewater, and the pretreated saline wastewater enters the membrane concentration unit II for treatment to obtain concentrated salt waste water and clean water. The TDS value of the total solids dissolved in water in the resulting concentrated salt wastewater is 35000mg / L, and the ion species in the concentrated salt wastewater is mainly Na + , SO 4 2- , Cl - .

[0065] Concentrated salt wastewater mixed with organic materials enters the supercritical water treatment unit together, enters the supercritical water treatment reactor after heat exchange, and reacts with the oxi...

Embodiment 2

[0069] The saline wastewater B used in this example comes from the coal chemical process. The total solids dissolved in the saline wastewater B has a TDS of 4000 mg / L and a COD of 150 mg / L.

[0070] The saline wastewater B enters the pretreatment unit for treatment, removes the interfering substances in the saline wastewater through biological treatment, chemical treatment and filtration, and obtains the pretreated saline wastewater, and the pretreated saline wastewater enters the membrane concentration unit for treatment to obtain Concentrated salt wastewater and clean water. The TDS value of the total solids dissolved in water in the resulting concentrated salt wastewater is 30000mg / L, and the ion species in the concentrated salt wastewater is mainly Na + , SO 4 2- , Cl - .

[0071] Concentrated salt wastewater mixed with co-oxidant enters supercritical water treatment unit together, enters supercritical water treatment reactor after heat exchange, reacts with oxidant un...

Embodiment 3

[0075] The saline wastewater A used in this example. The saline wastewater A enters the pretreatment unit for treatment, removes the interfering substances in the saline wastewater through biological treatment, chemical treatment and filtration, and obtains the pretreated saline wastewater, and the pretreated saline wastewater enters the membrane concentration unit II for treatment. Obtain concentrated salt wastewater and clear water. The TDS value of the total solids dissolved in water in the resulting concentrated salt wastewater is 35000mg / L, and the ion species in the concentrated salt wastewater is mainly Na + , SO 4 2- , Cl - .

[0076] Concentrated salt wastewater, materials containing organic matter and co-oxidant are mixed together into supercritical water treatment unit III, and then enter supercritical water treatment reactor after heat exchange, and react with oxidant under supercritical reaction conditions. The oxidant is air, and the The organic matter-conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com