Method for rapidly concentrating 16 polycyclic aromatic hydrocarbons in water

A polycyclic aromatic hydrocarbon and water quality technology, applied in the field of environmental monitoring and analytical chemistry, can solve the problems of target loss, difficult practical application, complicated operation process, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

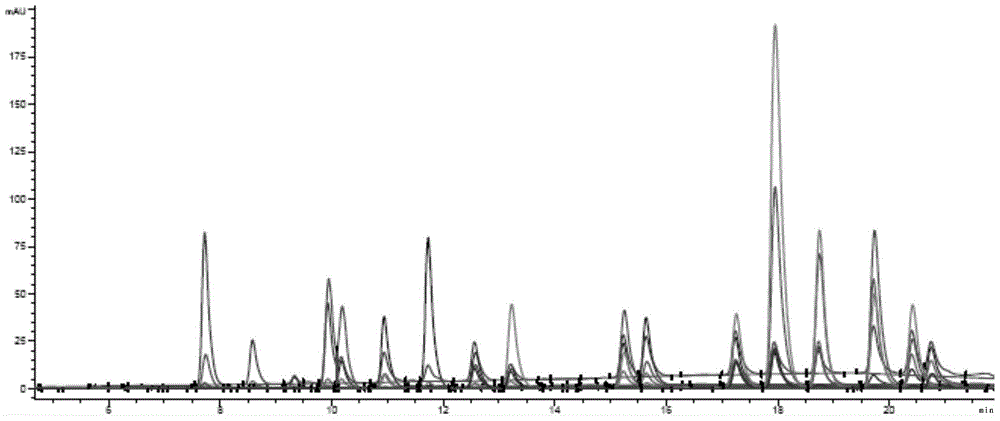

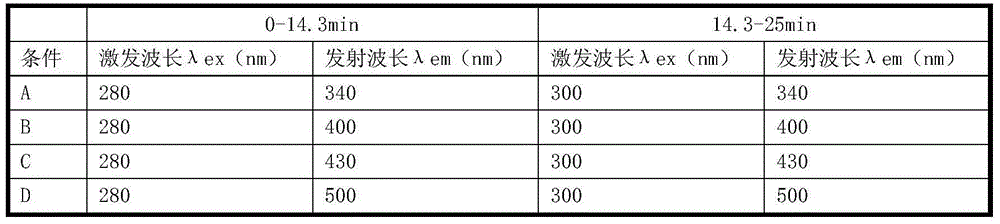

[0025] Concentration conditions: use the concentration device Turbo Vap II type automatic nitrogen blowing concentrator (Sweden Biotage Company, formerly the U.S. Caliper Life Sciences company) to prepare 150ml of 4ug / l 16 kinds of PAHs mixed standard sample / dichloromethane solution at the temperature of the water bath Concentrate to about 1.0mL at 30°C and nitrogen pressure of 9-13psi, add 5mL of chromatographically pure acetonitrile, then use a nitrogen blower to concentrate to 1.0mL at a water bath temperature of 50°C, pass through a 0.45um filter membrane, and sample 10uL Perform liquid chromatography detection.

[0026] Liquid chromatography detection conditions:

[0027] Agilent 1200 HPLC system: (USA) G1315D-DAD detector, G1321A-FLD fluorescence detector, Quaternary quaternary pump, G1316A-Colcom column oven, G1322A-Degasser vacuum degasser.

[0028] Liquid chromatography column: ZORBAX Eclipse PAH 4.6*250mm*5um

[0029] Injection volume: 10uL (automatic injection); C...

Embodiment 2

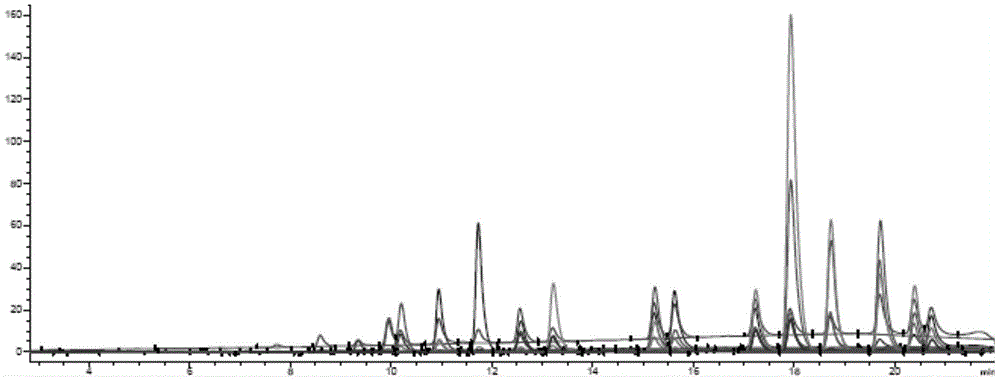

[0045] Concentration conditions: Use YH-RE rotary evaporator (Shanghai Yuhua Instrument Co., Ltd.) to concentrate the prepared 4ug / l 16 kinds of PAHs mixed standard sample / dichloromethane solution under the conditions of water bath temperature 30°C and vacuum degree 0.03MPa To 1-2ml, add 5mL of chromatographically pure acetonitrile, transfer to a common nitrogen blower, concentrate to 1.0mL at a water bath temperature of 50°C, pass through a 0.45um filter membrane, and sample 10uL for liquid chromatography detection.

[0046] The detection conditions of liquid chromatography are the same as in Example 1.

[0047] The concentrated recovery results are shown in Table 4, and the spectrograms are shown in figure 2 .

[0048] Table 4 4ppm mixed standard sample / dichloromethane solution rotary evaporation concentration data

[0049]

[0050]

Embodiment 3

[0052] Extraction conditions: add 2ug 16 polycyclic aromatic hydrocarbon mixed standard samples to 1L blank water sample, put it into a 2000mL separatory funnel, add an appropriate amount of decafluorobiphenyl liquid as a recovery indicator, in order to improve extraction efficiency and reduce emulsification phenomenon, shorten the separation time of the two phases, and add an appropriate amount of 30g NaCl to the water phase. Add about 50mL of dichloromethane, shake gently and release the gas, repeat this action several times, after fully deflated, vibrate vigorously for about 10min in an airtight condition, and collect the dichloromethane solution in the lower layer in 250mL in a triangular beaker. Repeat the extraction twice, combine the organic phases, and add anhydrous sodium sulfate until flowing anhydrous sodium sulfate exists.

[0053] The concentration and replacement conditions of the dichloromethane extract, and the liquid chromatography detection conditions are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com