Purification method of isopropanol

A purification method, the technology of isopropanol, applied in the direction of separation method, chemical instrument and method, separation/purification of hydroxyl compounds, etc., can solve the problems of large investment in energy-consuming equipment, environment, product pollution, etc., and achieve increased production costs, Effect of increasing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

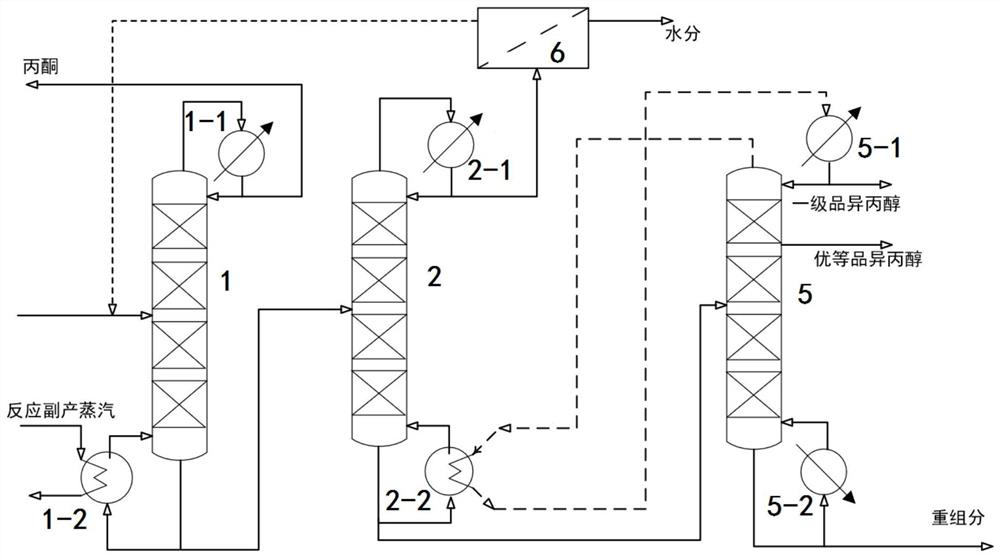

[0085] This embodiment adopts figure 2 The purification device shown.

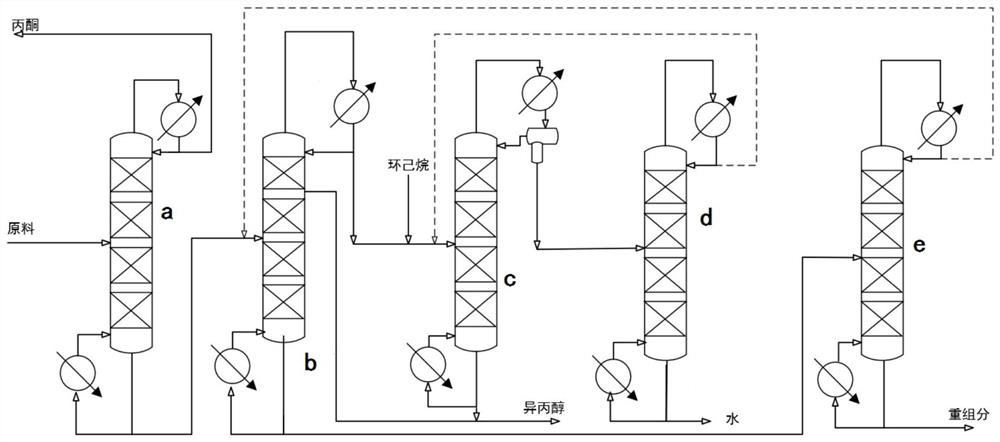

[0086] First, the crude product of isopropanol is separated from the top of the tower through acetone-removing rectification tower to separate light component acetone, the temperature at the top of the tower is 50°C, and the temperature at the bottom of the tower is 80°C.

[0087] Then, the crude product from the bottom of the acetone-removing tower is passed into the dehydration tower for continuous pressurized rectification, and the crude isopropanol containing a small amount of water is obtained from the bottom of the tower.

[0088] The temperature at the top of the dehydration tower is 100°C. The steam rising from the top of the tower is heated to the reboiler of the secondary dehydration tower. The uncondensed part of the gas phase is condensed by the condenser and enters the reflux tank. After being pressurized by the reflux pump, some Back to the dehydration tower. The other part of the isopropa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com