Rapid-heating-assisted ultrasonic stripping method for two-dimensional nanometer Ti3C2 lamella

A two-dimensional nano-ultrasonic peeling technology, which is applied in the direction of nanotechnology, can solve the problem of poor peeling effect of sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: In this embodiment, a rapid heating-assisted ultrasonic exfoliation of two-dimensional nano-Ti 3 C 2 The layer-by-layer method is accomplished in the following steps:

[0017] 1. After mixing Ti, Al, and C powders in a molar ratio of 3:(1~1.1):2, they are subjected to pressureless sintering at 1400°C to 1500°C to obtain Ti 3 AlC 2 phase ceramics, and then crush it through 400 mesh to obtain Ti 3 AlC 2 powder;

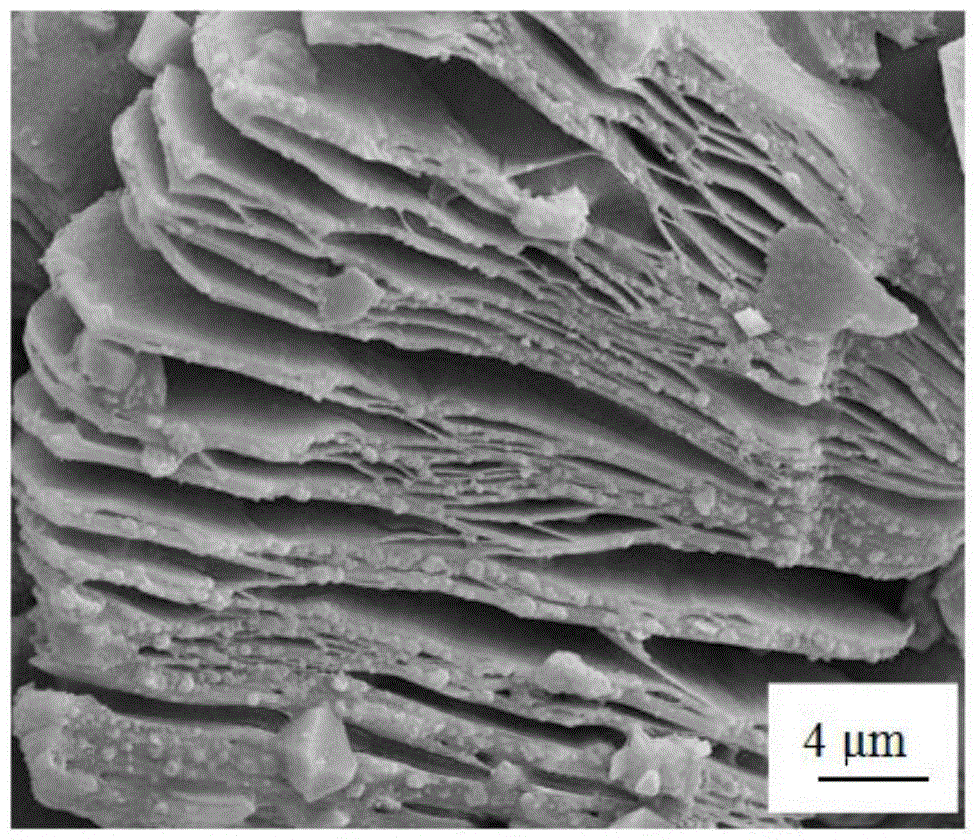

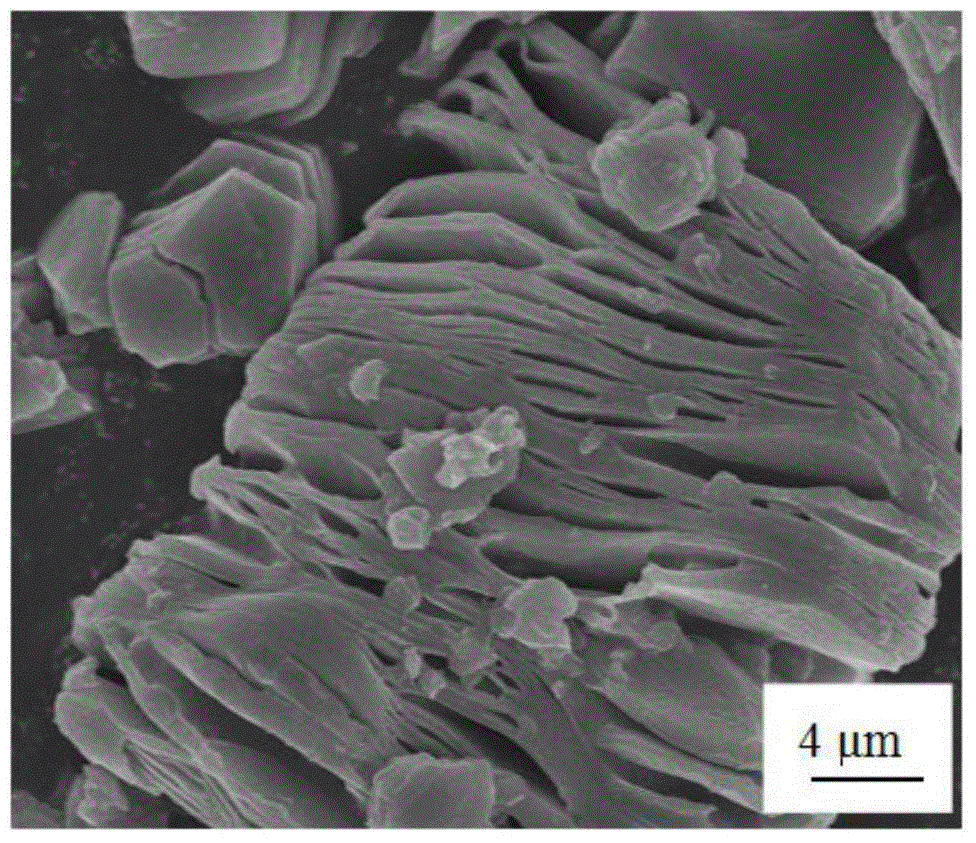

[0018] Second, the Ti 3 AlC 2 The powder is corroded in hydrofluoric acid with a concentration of 20wt.% to 50wt.% for 4 to 24 hours, and then added to deionized water for centrifugation to remove the liquid phase, and then dry the solid phase to obtain stacked lamellar Ti 3 C 2 T x Powder;

[0019] 3. The layered Ti layer that will be stacked 3 C 2 T x Put the powder into a quartz glass tube, close the tube mouth after vacuuming, and then immediately put it into a heat treatment furnace at a constant temperature of 600-1200 ° ...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the speed of centrifugation in step 2 is 3500 r / min. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying described in step 2 refers to drying at 30-80° C. for 12 hours. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com