Preparation method and application of double-function micro-nano hierarchical structural zinc oxide power

A hierarchical structure, zinc oxide powder technology, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of complex experimental operation, high reaction temperature, difficult to obtain performance, etc., and achieve cheap and easy raw materials. It has the advantages of simple preparation process and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

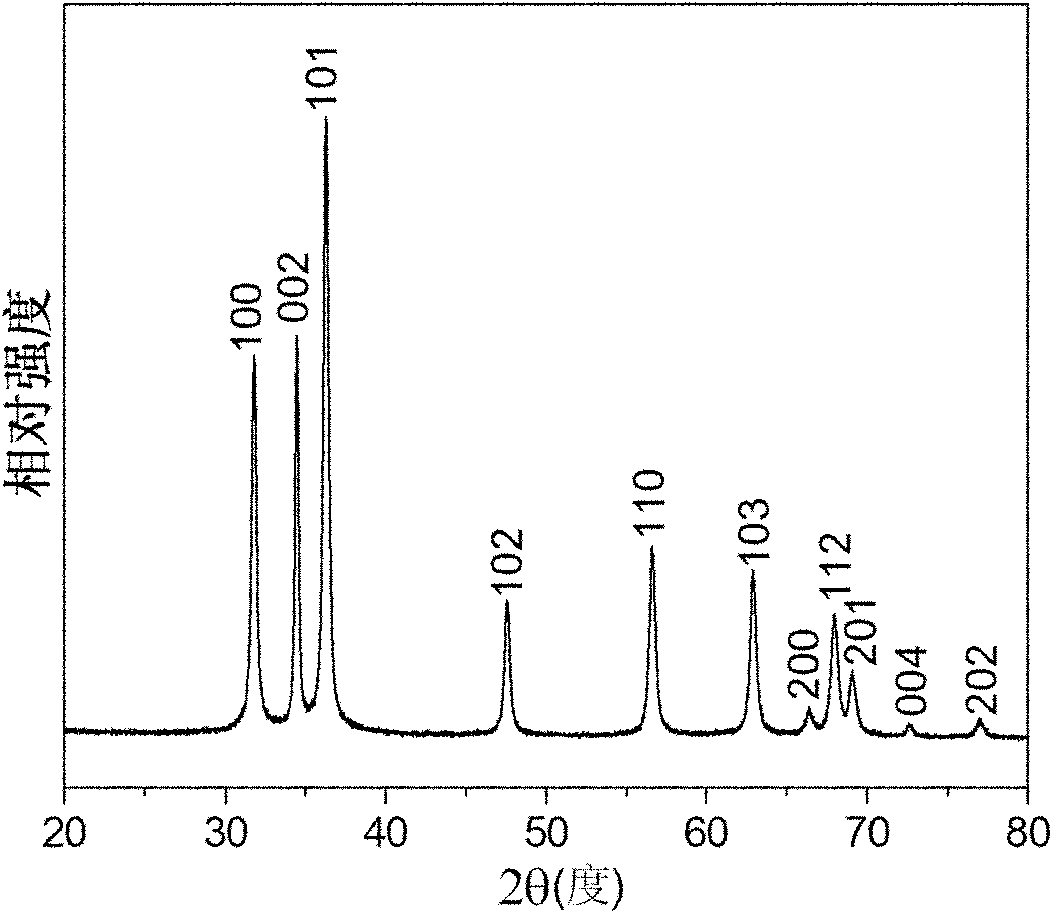

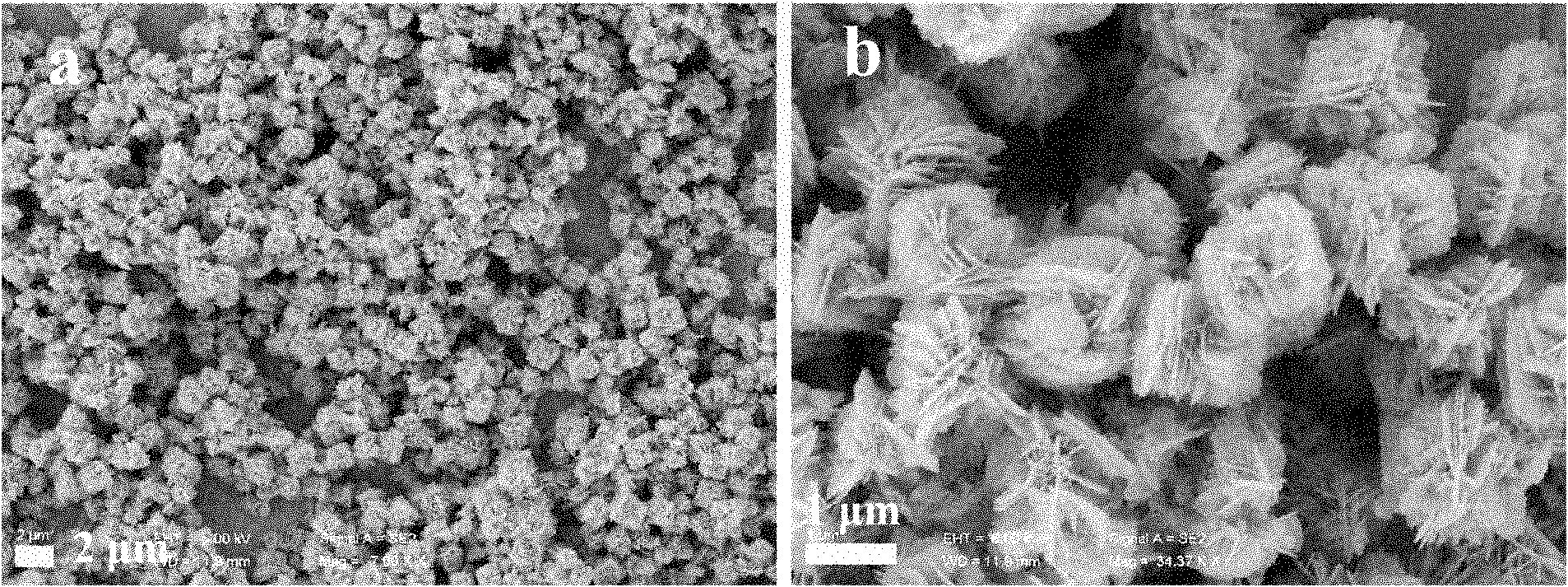

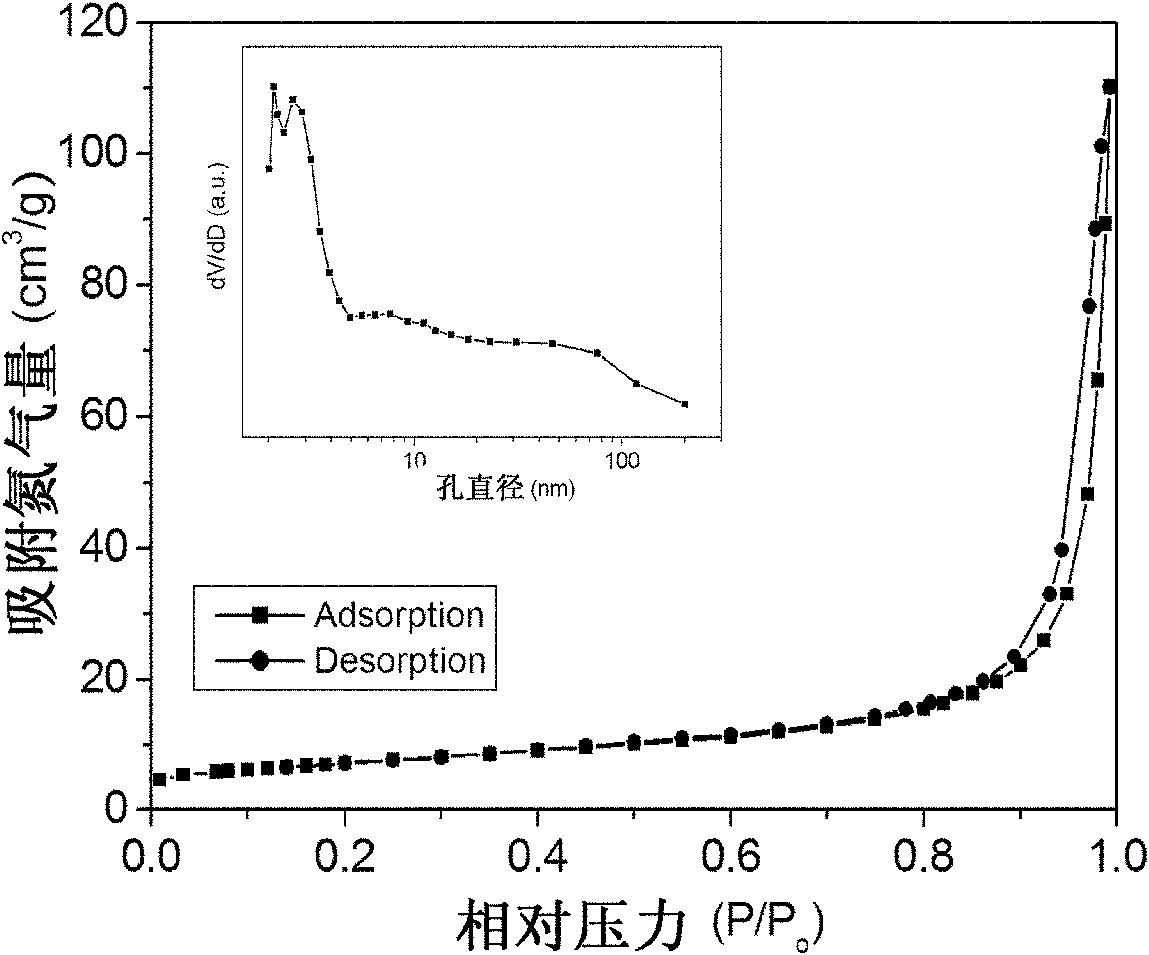

[0028] 2 mmol of anhydrous zinc chloride ZnCl 2 and 10 mmol of sodium hydroxide NaOH were dissolved in 30 mL of deionized water. Put the solution in a 60mL capped glass bottle and keep the temperature at 80°C for 12 hours; the obtained white precipitate was centrifuged with a centrifuge, washed 4 times with deionized water, and then dried in a drying oven at 80°C for 12 hours to obtain high photocatalysis Active ZnO powder with micro-nano hierarchical structure.

[0029] Disperse 0.2090g of the prepared ZnO powder and 0.0595g of stearic acid in 20mL of ethanol at a molar ratio of 100:8, mix them uniformly by ultrasonic treatment, and evaporate the absolute ethanol to dryness at 50°C to obtain superhydrophobic Sexual ZnO nano powder coating.

Embodiment 2

[0031] Weigh 2mmol of ZnCl 2And the NaOH of 8mmol; Operating procedure is the same as embodiment 1, reacts at 100 ℃ of constant temperature 8 hours, can obtain the ZnO nano-powder of the micro-nano hierarchical structure of high photocatalytic activity equally; The same method as in Example 1 was modified to prepare the coating, so that the molar content of stearic acid in the coating was 7%, to obtain a superhydrophobic ZnO nano-powder coating.

Embodiment 3

[0033] ZnSO 4 ·7H 2 O replaces ZnCl in Example 1 2 As zinc source, take ZnSO 4 ·7H 2 The mol ratio of O and NaOH is 1: 5, and operating procedure is identical with embodiment 1, reacts at 100 ℃ of constant temperature 8 hours, obtains the ZnO nano-powder of the micro-nano hierarchical structure of high photocatalytic activity; Then use gained ZnO nano-powder with Stearic acid is modified by the method in Example 1, so that the molar content of stearic acid in the coating is 8%, to obtain a superhydrophobic ZnO nanometer powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com