Superhydrophobic fabric or superhydrophobic non-woven fabric and preparation method thereof

A super-hydrophobic and non-woven fabric technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of complex preparation process of super-hydrophobic fabrics or super-hydrophobic non-woven fabrics, short duration of modification effect, and inability to wash. Achieve the effect of avoiding large-scale equipment, good market prospects and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 superhydrophobic PET fabric (fabric 1)

[0031] The PET (weight-average molecular weight = 300,000) fabric was ultrasonically cleaned in ethanol and water for 3 minutes, and then vacuum-dried at 60° C. to constant weight. Put 5g PET fabric into the container containing long chain alkane monomer (CH2 =CHC(O)O(CH 2 ) 10 CH 3 ) of ethanol solution 100mL (the concentration of the monomer in the ethanol solution containing the monomer is 2wt%) glass Erlenmeyer flask, nitrogen gas 10min after airtight, in 60 After irradiating 5kGy in the Co cobalt source, the fabric was taken out and extracted in a Soxhlet extractor for 72 hours with methyl ethyl ketone as a solvent, and then vacuum-dried to constant weight at 60°C to obtain a superhydrophobic PET fabric (fabric 1), which contained The grafting ratio of long-chain alkane monomer was 11.3%.

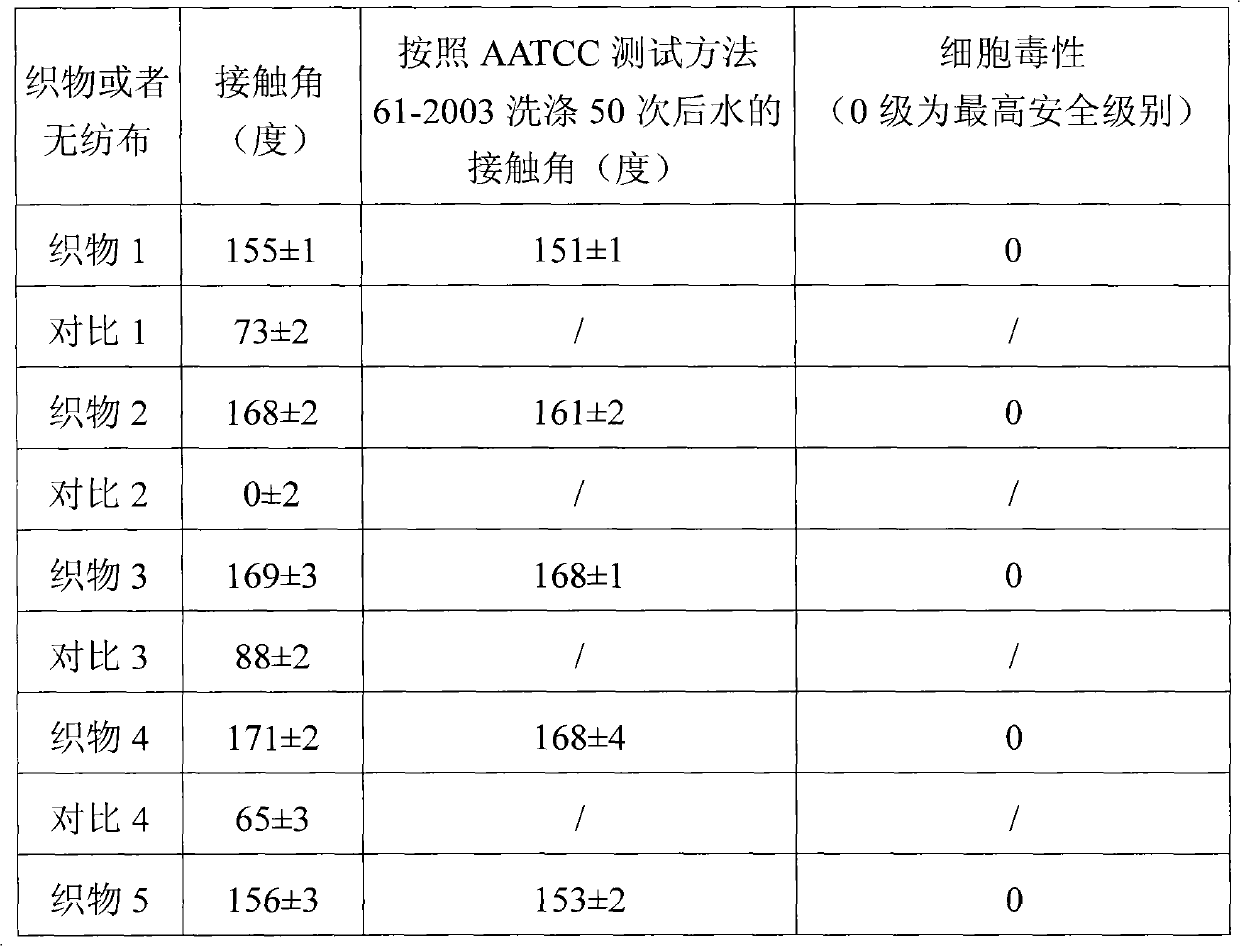

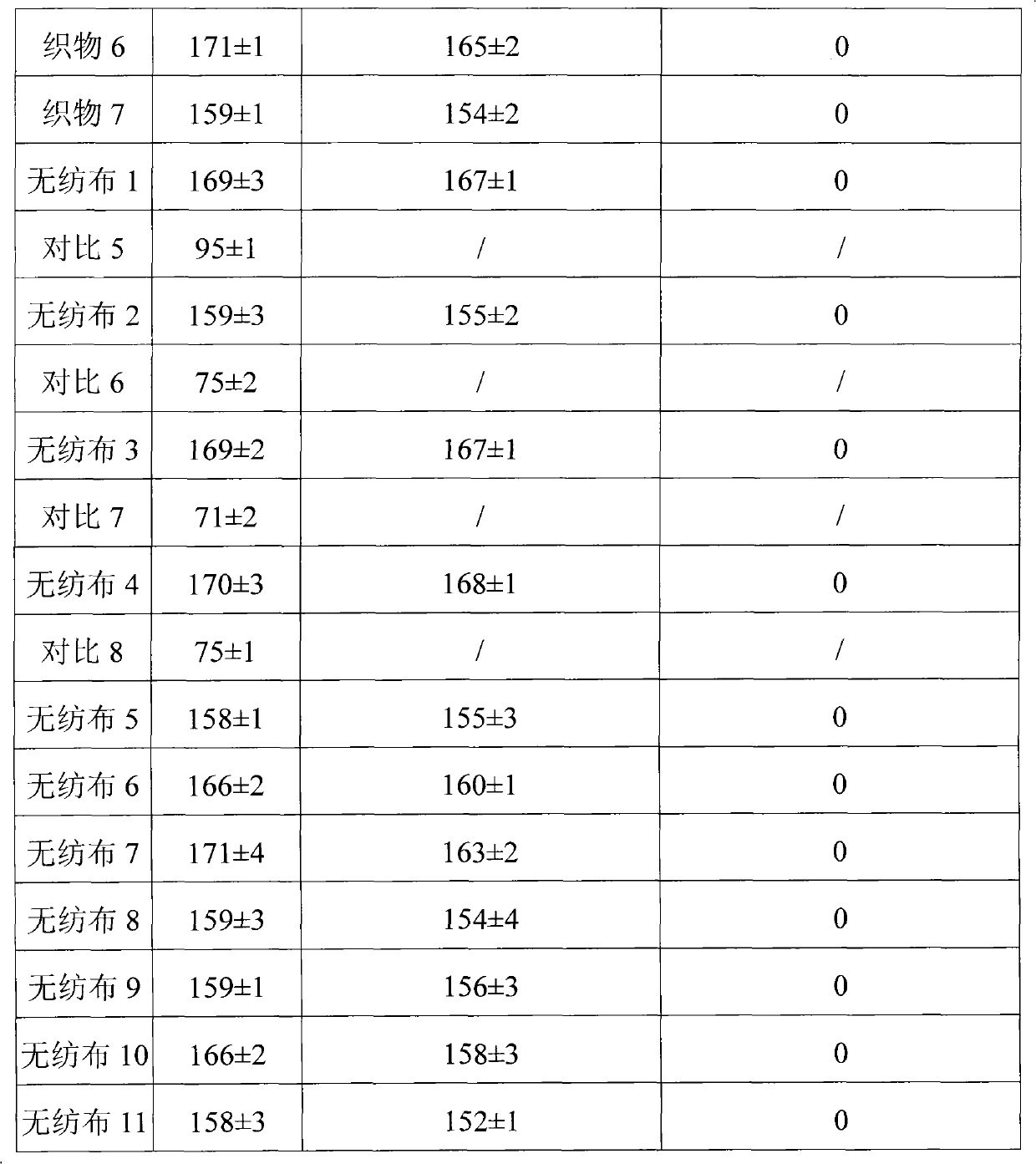

[0032] After the prepared fabric 1 was washed 50 times according to AATCC test method 61-2003, the c...

Embodiment 2

[0037] The preparation of embodiment 2 superhydrophobic cotton fabrics (fabric 2)

[0038] The cotton fabrics were ultrasonically cleaned in ethanol and water for 3 minutes, and then vacuum-dried at 60 °C to constant weight. 5g cotton fabric is put into containing long-chain alkane monomer (CH 2 =C(CH 3 )C(O)O(CH 2 ) 17 CH 3 ) of methanol solution 100mL (the concentration of the monomer in the methanol solution containing the monomer is 10wt%) glass Erlenmeyer flask, nitrogen gas 20min after airtight, in 60 After irradiating 25kGy in the cobalt source, the fabric was taken out and extracted in a Soxhlet extractor for 72 hours with methyl ethyl ketone as a solvent, then vacuum-dried to constant weight at 60°C to obtain a superhydrophobic cotton fabric (fabric 2), which contained The graft ratio of long-chain alkane monomer is 22.0%.

[0039] Test the contact angle of fabric 2, and the test method is the same as that in Example 1. The measurement results show that the ave...

Embodiment 3

[0042] The preparation of embodiment 3 superhydrophobic polypropylene fabric (fabric 3)

[0043] Hydrophobic polypropylene (weight-average molecular weight = 400,000) fabrics were ultrasonically cleaned in ethanol and water for 3 minutes, and then vacuum-dried at 60° C. to constant weight. Put 5g polypropylene fabric into the container containing long chain alkane monomer (CH 2 =C(CH 3 )C(O)O(CH 2 ) 16 CH 3 ) of ethanol solution 100mL (the concentration of the monomer in the ethanol solution containing the monomer is 50wt%) glass Erlenmeyer flask, nitrogen gas 30min after airtight, in 60 After irradiating 50kGy in the Co cobalt source, the fabric was taken out and extracted in a Soxhlet extractor for 72 hours with methyl ethyl ketone as a solvent, then vacuum-dried at 60°C to constant weight to obtain a superhydrophobic polypropylene fabric (fabric 3), which contained The grafting rate of long-chain alkane monomer is 37.4%.

[0044] The contact angle of the prepared fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com