Superhydrophobic fabric or nonwoven fabric and preparation method thereof

A non-woven, super-hydrophobic technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of intolerance to washing, short duration of modification effect, complicated preparation process of super-hydrophobic fabrics or non-woven fabrics, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

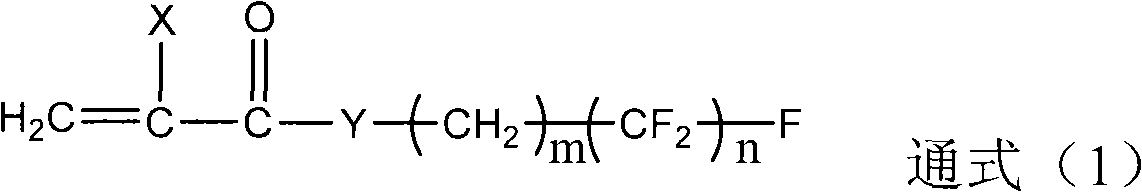

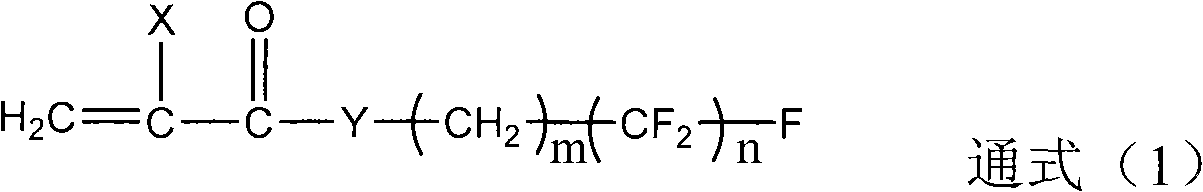

[0028] The preparation of embodiment 1 superhydrophobic PET fabric (fabric 1)

[0029] The PET (weight-average molecular weight=300,000) fabric was ultrasonically cleaned in ethanol and water for 3 minutes, and then vacuum-dried at 60° C. to constant weight. Put 5g of PET fabric into a container containing 2% (w / w) fluorine-containing monomer (CH 2 =CHC(O)OCH 2 CH 2 (CF 2 ) 4 F) in a glass Erlenmeyer flask of 100mL methanol solution, after being airtight with nitrogen for 10min, in 60 After irradiating 5kGy in the cobalt source, the fabric was taken out and extracted in a Soxhlet extractor with butanone as a solvent for 72 hours, then vacuum-dried at 60°C to constant weight, and the grafting rate of fluorine-containing monomer was 15%.

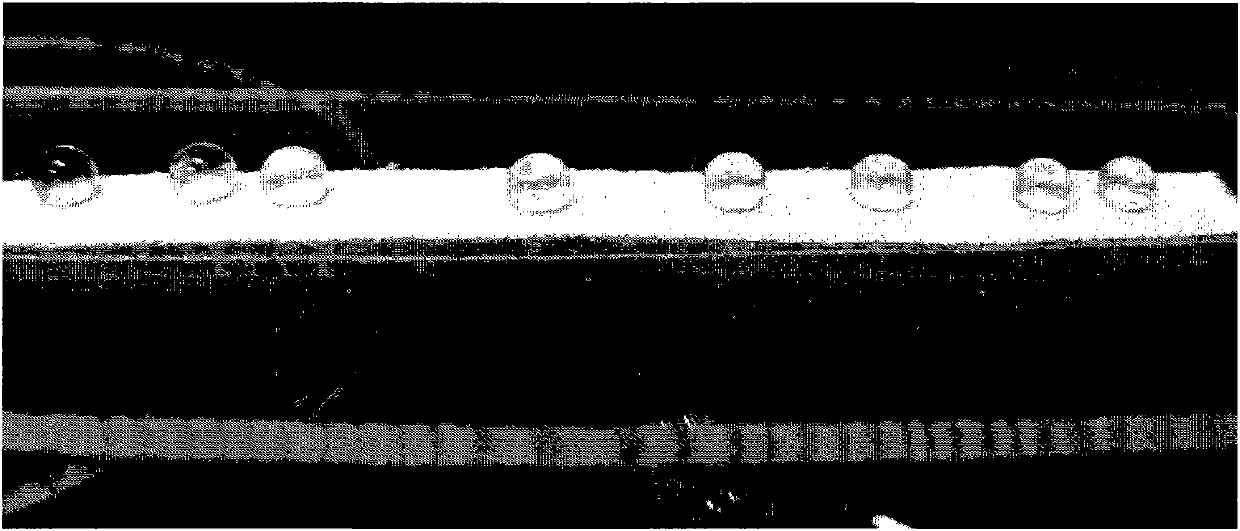

[0030] The obtained superhydrophobic PET fabric was washed 50 times according to AATCC test method 61-2003, and the contact angle of water on the fabric surface before and after washing was measured (each sample was measured at least 8 ti...

Embodiment 2

[0035] The preparation of embodiment 2 superhydrophobic cotton fabrics (fabric 2)

[0036] Cotton fabrics were ultrasonically cleaned in ethanol and water for 3 min, and then vacuum-dried at 60 °C to constant weight. Put 5g of cotton fabric into a container containing 0.5% (w / w) fluorine-containing monomer (CH 2 =C(CH 3 )C(O)OCH 2 (CF 2 ) 8 F) In the glass Erlenmeyer flask of 100mL methanol solution, after being airtight with nitrogen for 20min, in 60 After irradiating 25kGy in the cobalt source, the fabric was taken out and extracted in a Soxhlet extractor for 72 hours with methyl ethyl ketone as a solvent, then vacuum-dried at 60°C to constant weight, and the grafting rate of fluorine-containing monomer was 12%.

[0037]The obtained superhydrophobic cotton fabric was washed 50 times according to AATCC test method 61-2003, and the contact angle of water on the surface of the fabric before and after washing was measured (each sample was measured at least 8 times at differ...

Embodiment 3

[0041] The preparation of embodiment 3 superhydrophobic polypropylene fabric (fabric 3)

[0042] Hydrophobic polypropylene (weight-average molecular weight = 400,000) fabrics were ultrasonically cleaned in ethanol and water for 3 minutes, and then vacuum-dried at 60 degrees Celsius to constant weight. Put 5g of polypropylene fabric into a container containing 10% (w / w) fluorine-containing monomer (CH 2 =C(CN)C(O)OCH 2 (CF 2 ) 6 F) In the glass Erlenmeyer flask of 100mL methanol solution, after passing nitrogen gas for 30min and sealing, in 60 After irradiating 50kGy in the cobalt source, the fabric was taken out and extracted in a Soxhlet extractor with butanone as a solvent for 72 hours, then vacuum-dried at 60 degrees Celsius to constant weight, and the grafting rate of fluorine-containing monomer was 23.4%.

[0043] The prepared superhydrophobic polypropylene fabric was washed 50 times according to AATCC test method 61-2003, and the contact angle of water on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com