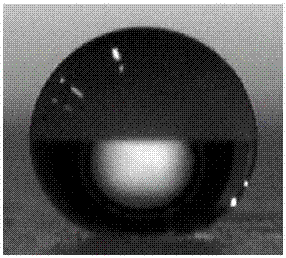

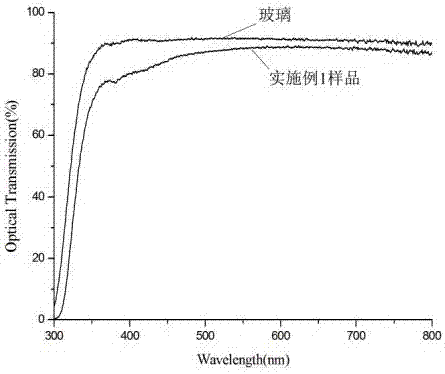

Preparation method of highly transparent wear-resistant superhydrophobic composite coating

A composite coating, super-hydrophobic technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of cumbersome operation, low application value, not enough environmental protection, etc., and achieve the effect of simple preparation method and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 0.835g epoxy resin E51, 0.084g ethylene glycol diglycidyl ether, and 0.418g curing agent T31 evenly, stir for 15 minutes, then dip a certain amount with a blade and apply it on the glass substrate, and dry it at room temperature After 1 hour, the glue started to solidify.

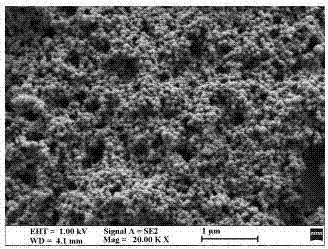

[0027] (2) Mix 12.4mL tetraethyl orthosilicate and 97.2mL absolute ethanol, reflux and stir at 60°C for 10min, then add dropwise a mixture of 7.8mL ammonia water and 1mL deionized water, and continue stirring for 2 hours. Keep stirring under reflux at 60°C, add 5.5mL methyltriethoxysilane dropwise, continue stirring for 1 hour, age for 1 day, and then put it in an oven at 60°C for 2 days to volatilize the solvent to obtain a modified surface hydrophobicity. Sexual nano-silica powder.

[0028] (3) Put 0.65g of silica powder in 50mL of absolute ethanol, reflux and stir at 60°C for 1 hour, and then ultrasonically disperse at room temperature for 1 hour to obtain a superhydrophobic silica disper...

Embodiment 2

[0032] (1) Mix 0.628g epoxy resin E51 with 0.094g n-butyl glycidyl ether, then add 0.314g curing agent T31 and mix well, stir for 15 minutes, then dip a certain amount with a blade and apply it on the glass substrate, room temperature After drying for 1 hour, the glue starts to solidify.

[0033] (2) Mix 37.2mL tetraethyl orthosilicate and 291.6mL absolute ethanol, reflux and stir at 60°C for 10min, then add dropwise a mixture of 23.37mL ammonia water and 3mL deionized water, and continue stirring for 2 hours. Keep stirring under reflux at 60°C, add 16.6mL methyltriethoxysilane dropwise, continue stirring for 1 hour, age for 1 day, and then put it in an oven at 60°C for 2 days to volatilize the solvent to obtain a modified surface hydrophobicity. Sexual nano-silica powder.

[0034] (3) Put 1.3g of silica powder in 100mL of absolute ethanol, reflux and stir at 60°C for 1 hour, and then ultrasonically disperse at room temperature for 1 hour to obtain a superhydrophobic silica d...

Embodiment 3

[0038] (1) Mix 1.674g epoxy resin E51 with 0.251g n-butyl glycidyl ether, then mix with 0.837g curing agent T31 evenly, stir for 15 minutes, then dip a certain amount with a blade and apply it on the glass substrate, at room temperature After drying for 1 hour, the glue starts to solidify.

[0039] (2) Mix 24.8mL tetraethyl orthosilicate and 194.4mL absolute ethanol, reflux and stir at 60°C for 10 minutes, then add dropwise a mixture of 15.6mL ammonia water and 2mL deionized water, and continue stirring for 1 hour after dropping. Keep stirring under reflux at 60°C, add 16.6 mL of methyltriethoxysilane dropwise, and continue stirring for 1 hour to obtain a modified silica sol.

[0040] (3) Aging the modified silica sol obtained in step (2) for 1 day, and then drying it in an oven at 60°C to obtain a superhydrophobic silica aerogel.

[0041] (4) Put 0.975g of silica airgel in 75mL of absolute ethanol, reflux and stir at 60°C for 1 hour, and then ultrasonically disperse at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com