Niobium-containing high-strength hot-galvanized steel plate and production method thereof

A hot-dip galvanized steel sheet, high-strength technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc. And the overall performance is excellent, the production cost is low, and the implementation difficulty is small.

Inactive Publication Date: 2011-06-15

PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

View PDF12 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that in recent years, the requirements for the formability of steel sheets have become increasingly stringent, and proposals to improve the processing performance of such high-strength hot-dip galvanized steel sheets are also increasing, but there are few studies on the deep-drawing properties of high-strength hot-dip galvanized steel sheets

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

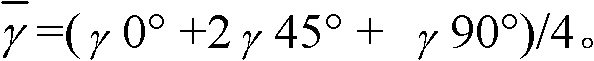

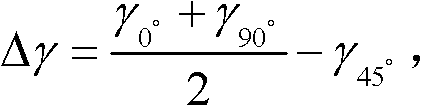

The invention relates to a niobium-containing high-strength hot-galvanized steel plate and a production method thereof. The invention provides a high-gamma-average-value low-Delta gamma-value structural niobium-containing high-strength hot-galvanized steel plate and a manufacturing method thereof. The niobium-containing high-strength hot-galvanized steel plate comprises the following components in percentage by mass: 0.03-0.1% of C, at most 0.05% of Si, 0.5-0.9% of Mn, at most 0.025% of P, at most 0.015% of S, at most 0.005% of N, at most 0.005% of Ti, 0.03-0.06% of Nb, 0.01-0.08% of Al, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: carrying out hot rolling on a steel billet, reeling, and carrying out acid washing, cold rolling, and carrying out hot galvanizing. The gamma average value of the Nb-containing high-strength hot-galvanized steel plate is greater than or equal to 1.3, the Delta gamma value is less than or equal to 0, the yield strength is greater than or equal to 460 MPa, the tensile strength is greater than or equal to 570 MPa, and the elongation at break is greater than or equal to 28%. The invention can ensure favorable forming property on the premise of ensuring high strength.

Description

A kind of niobium-containing high-strength hot-dip galvanized steel sheet and its production method technical field The invention belongs to the technical field of metal materials and their preparation, in particular to high-strength hot-dip galvanized steel sheets containing niobium for structures and a production method thereof. Background technique The use of high-strength steel plates is a major development trend of modern automotive steel. Generally speaking, as the strength of the steel plate increases, the formability decreases. It is a common wish of the automobile and steel industries to develop steel plates with both high strength and excellent formability. The plastic strain ratio (γ, Δγ value) is an important index to measure the formability of thin steel plates. The γ value is the plane normal plastic strain ratio, which indicates the thinning resistance of the plate and the uniform ductility of the plate surface. The plastic strain ratio of the steel plate γ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/14C22C38/12C21D1/26C23C2/06C23C2/40

Inventor 王敏莉郑之旺娄燕许哲峰梁英周一林张功庭王平利

Owner PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com