Well completion and oil production string of horizontal well and well completion and oil production processes thereof

A technology for well completion strings and horizontal wells, applied in the direction of wellbore/well parts, drill pipe, casing, etc., can solve problems such as edge-bottom water coning, water control failure, and ineffective isolation of oil and water layers, etc., to achieve The effect of delaying bottom water coning and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

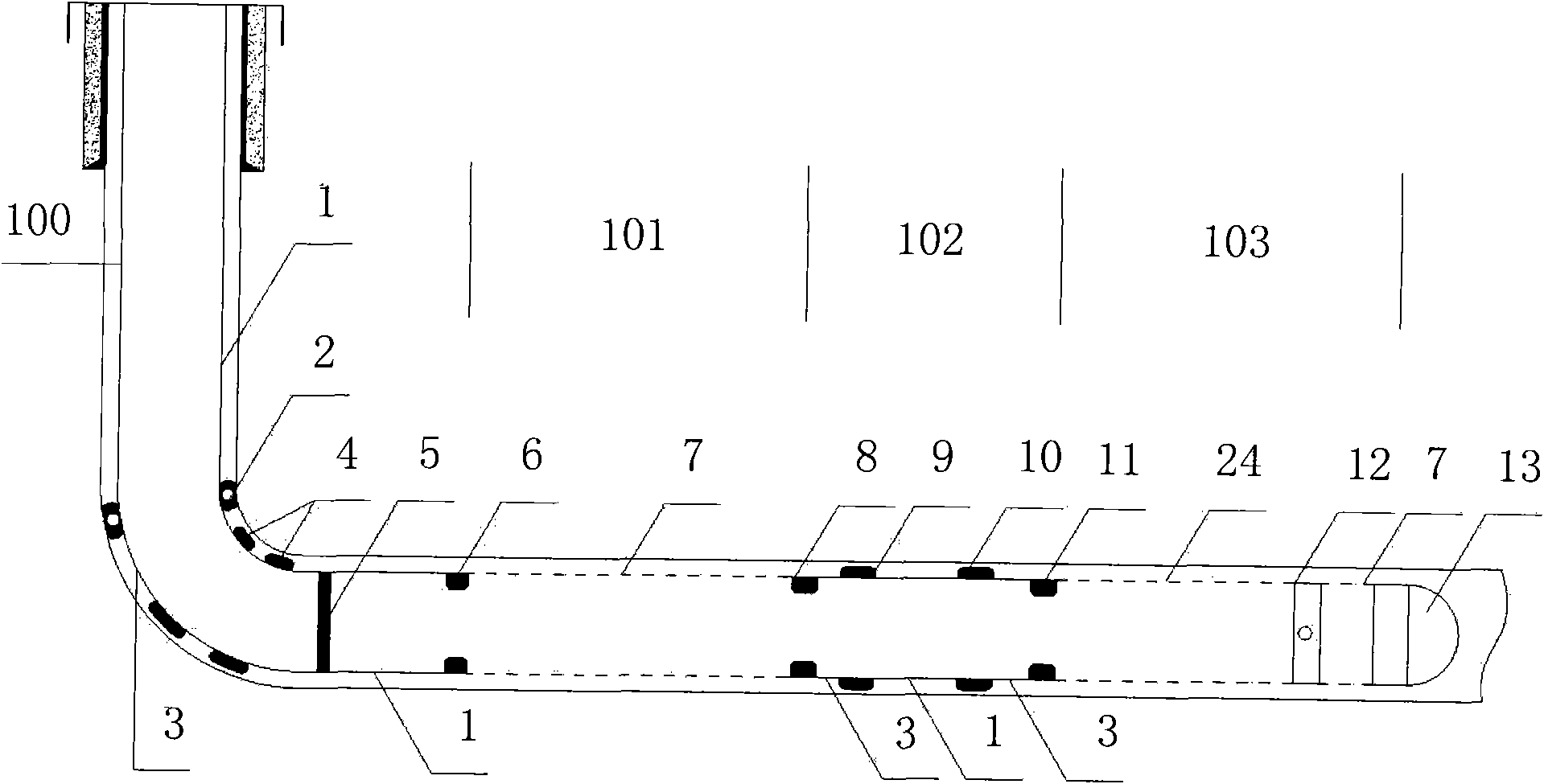

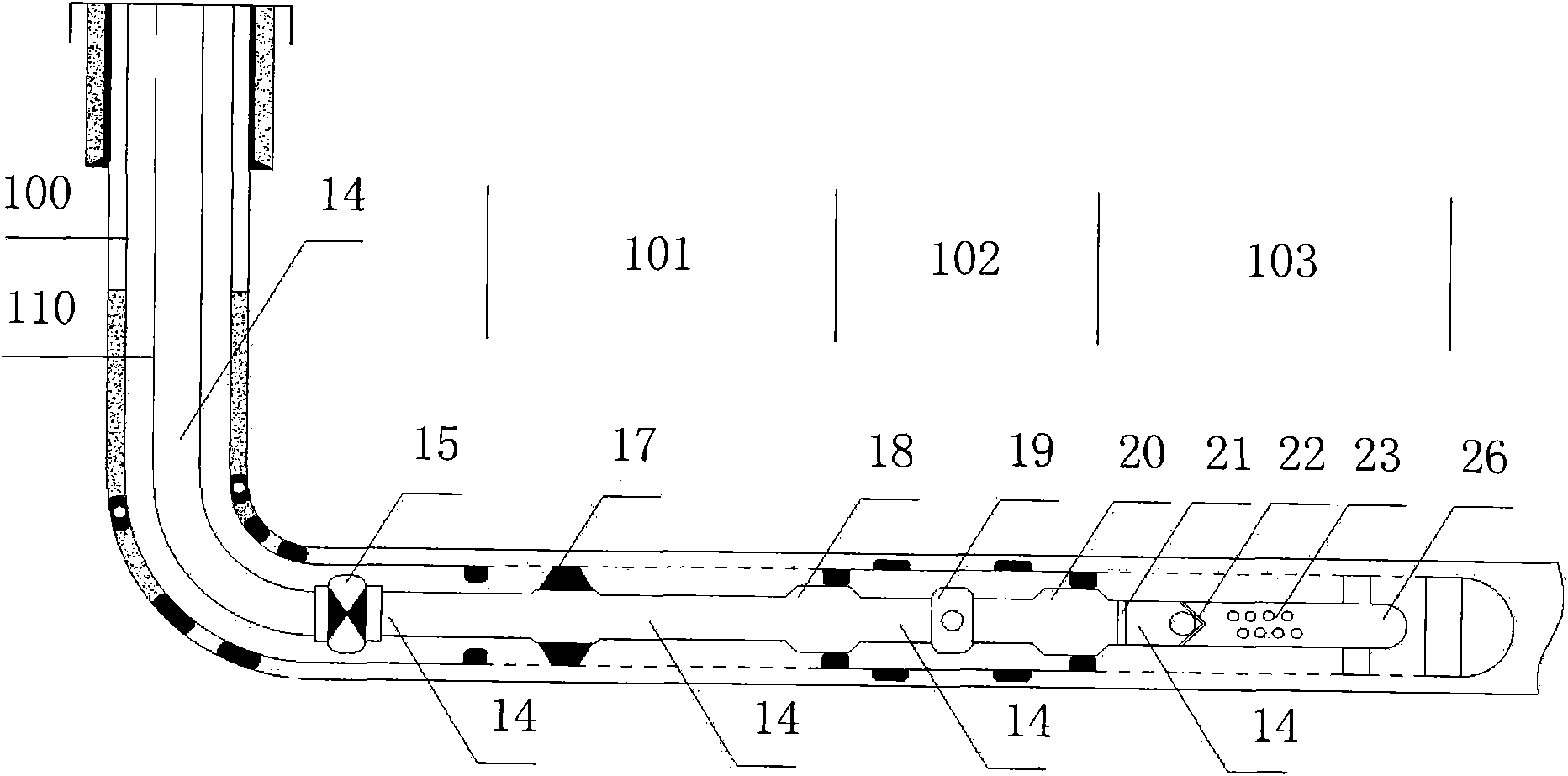

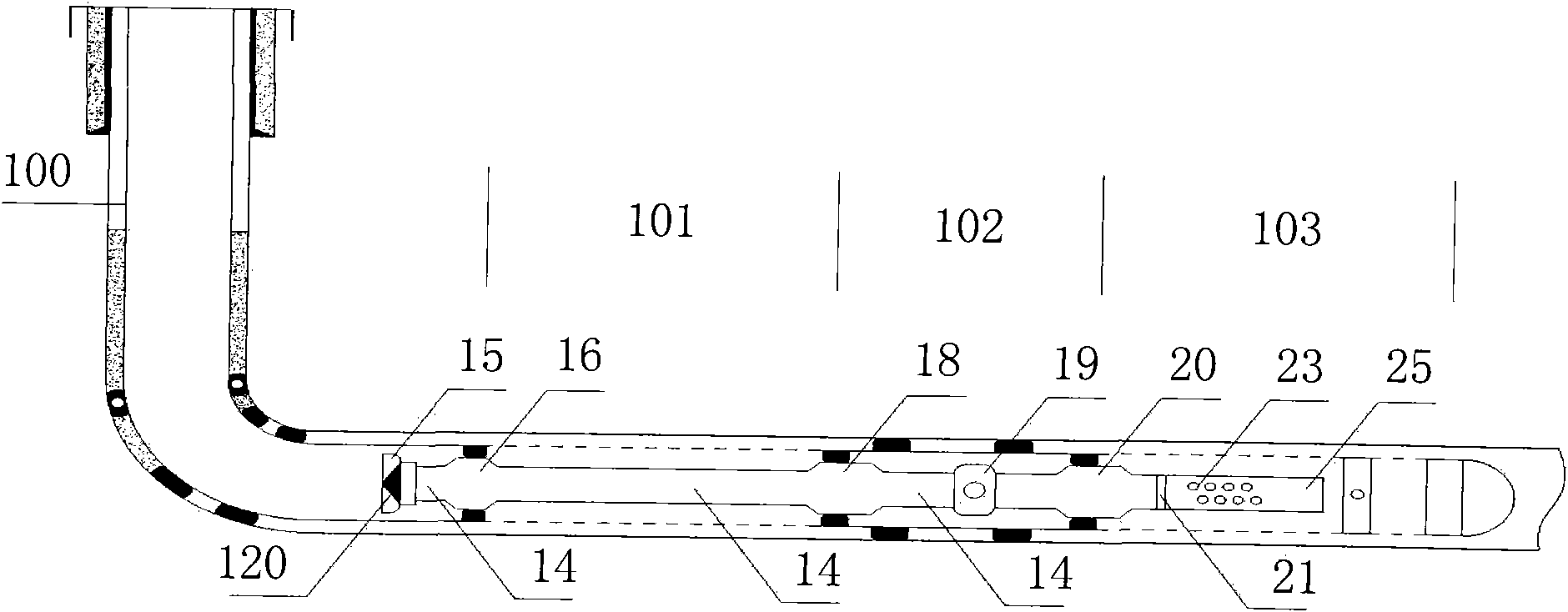

[0012] The completion and production string of the horizontal well and the completion and production technology of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The completion of the horizontal well of the present invention and the horizontal well section where the production string is located include an upper oil layer 101 , a water layer 102 and a lower oil layer 103 . The horizontal well section in the open-hole wellbore is fixedly installed with completion string 100 (see attached figure 1 ); the lower end of the casing 1 of the completion string 100 has a graded hoop 2, a casing nipple 3, an outer packer I 4, a blind plate 5, a casing 1, a layered sealing cylinder I 6, and an upper screen 7 , layered sealing cylinder II 8, casing nipple 3, outer packer II 9, outer packer III 10, casing nipple 3, layered sealing cylinder III 11, lower screen 24, well flushing The valve 12, the lower screen pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com