Completion pipe string for suspending bottom water coning

A well completion pipe string and coning technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems that it is difficult to achieve the expected effect, the operation process is complicated, and the on-site implementation is difficult. Oil and gas recovery rate, simple construction operation procedures, and the effect of extending the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

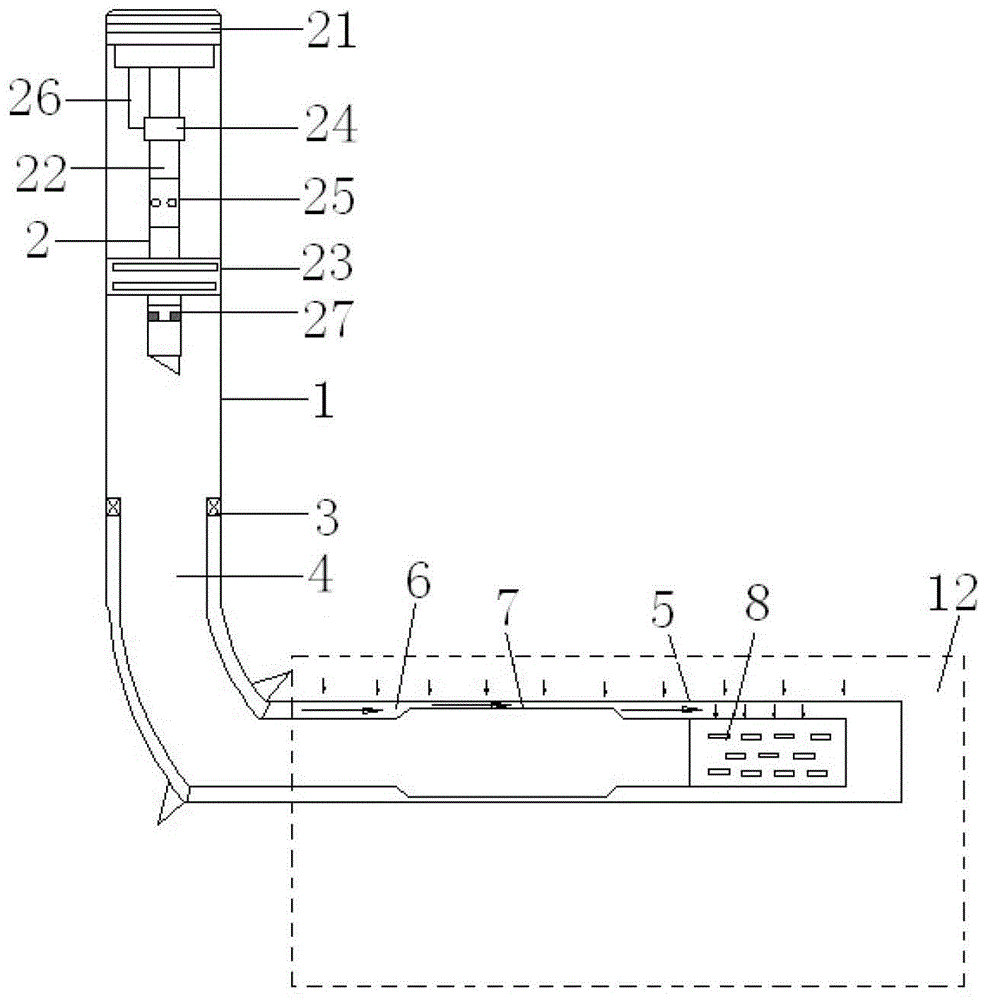

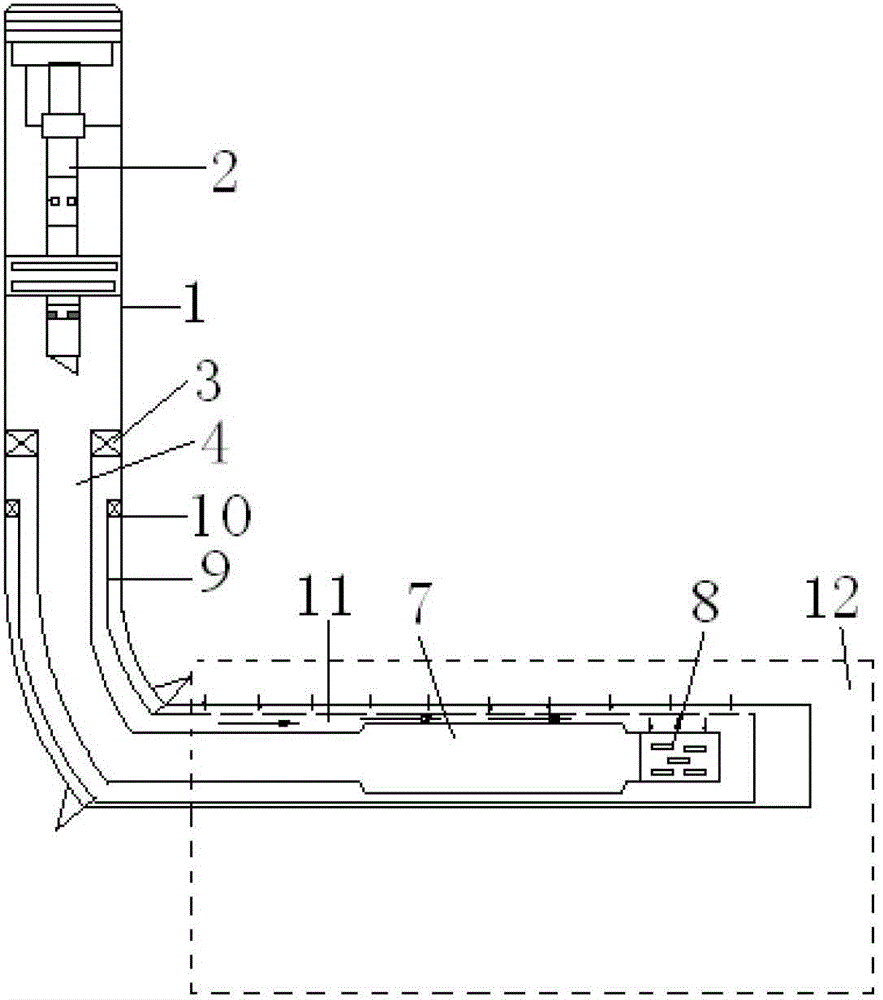

[0011] Such as figure 1 As shown, the present invention delays the bottom water coning by reducing the flow velocity of oil and gas entering the dead leg, and it includes a downhole casing 1 arranged in the vertical section of the oil and gas well, and a conventional production string 2 is arranged on the top of the downhole casing 1, The production tubing string 2 includes a tubing hanger 21, the lower end of the tubing hanger 21 is connected to a production tubing string 22, and the lower part of the production tubing string 22 is fixedly connected in the downhole casing 1 through a packer 23; A safety valve 24 and a circulating sliding sleeve 25 are arranged at intervals on the oil production string 22 in between, and the safety valve 24 is electrically connected to the control system outside the well through a control line 26; a seat joint 27 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com