Computer binocular vision denture scanning device and three-dimensional reconstruction method thereof

A technology of binocular vision and scanning device, applied in the field of denture scanning, can solve the problems of high cost, complex grating projection device and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

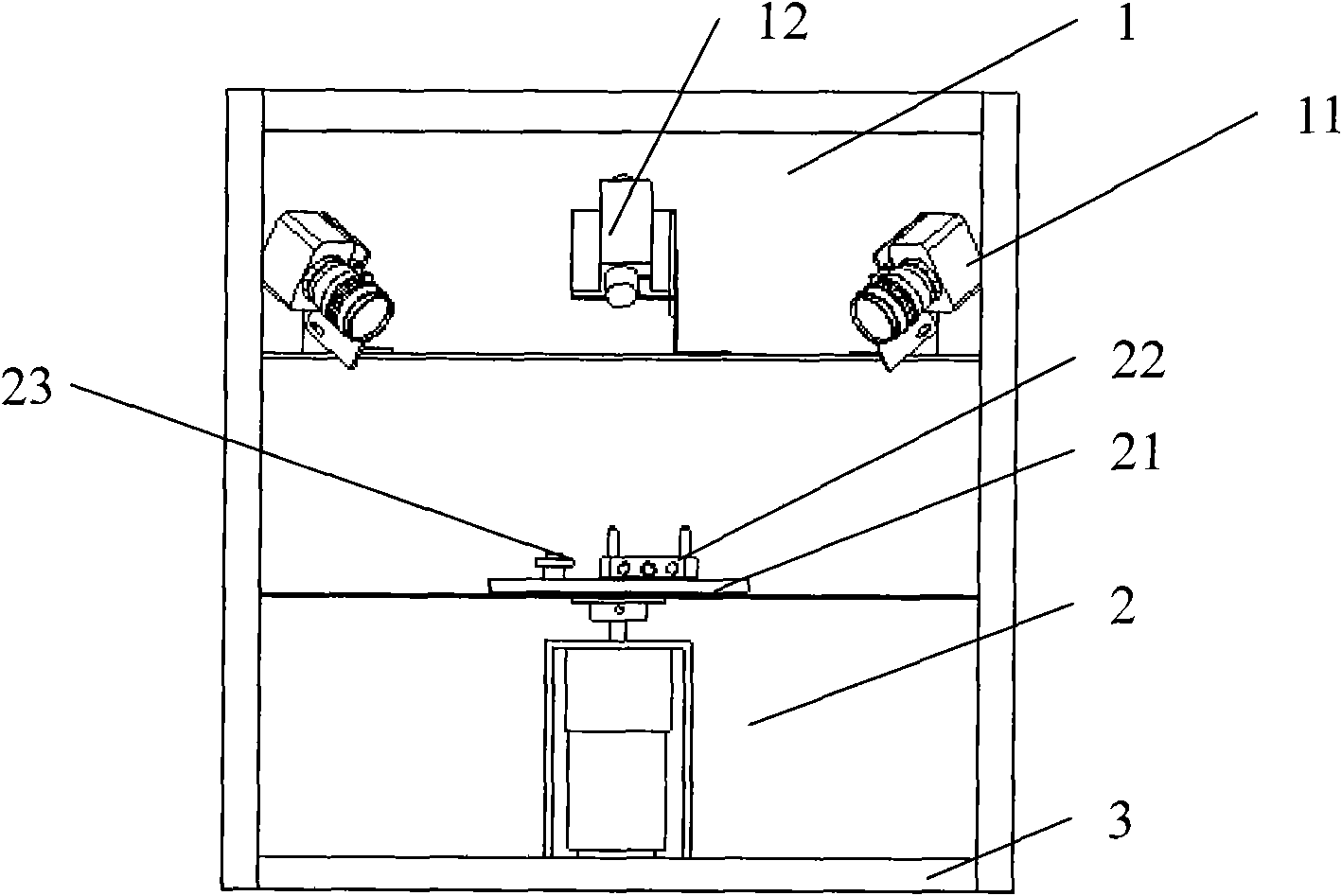

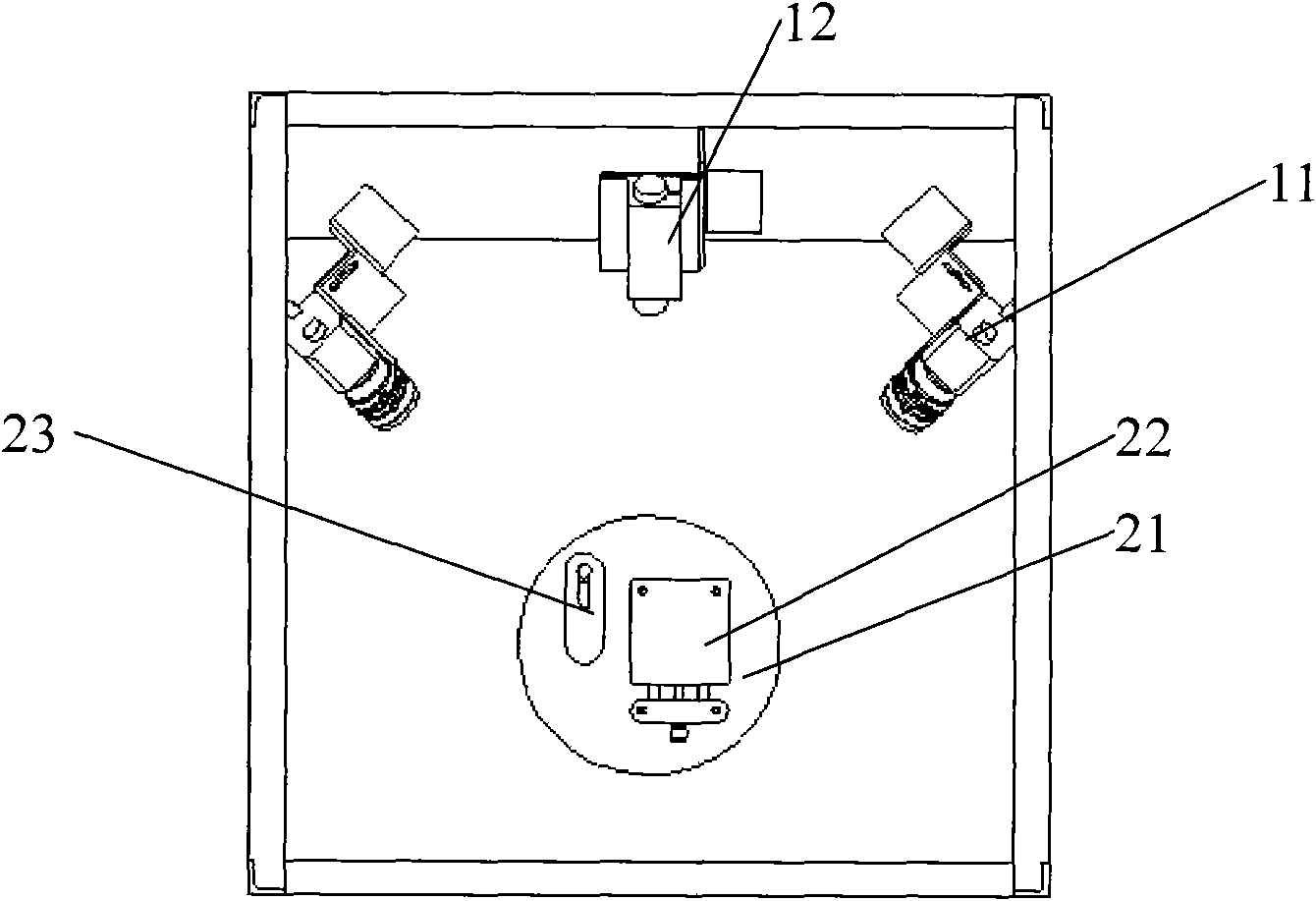

[0045] The device of the present invention is a measurement device integrating optical, mechanical and electrical technologies, such as Figure 1~4 As shown, the device includes:

[0046] Line-structured light vision collection part 1, rotating measuring table and its control part 2, and box body 3, wherein: line-structured light vision collection part 1 includes two high-resolution digital CCD cameras 11, one line-structured light laser 12, two The high-resolution digital CCD camera 11 is located above the center side of the rotating measuring platform and its control part 2, and is distributed symmetrically with the line structured light laser 12 as the center;

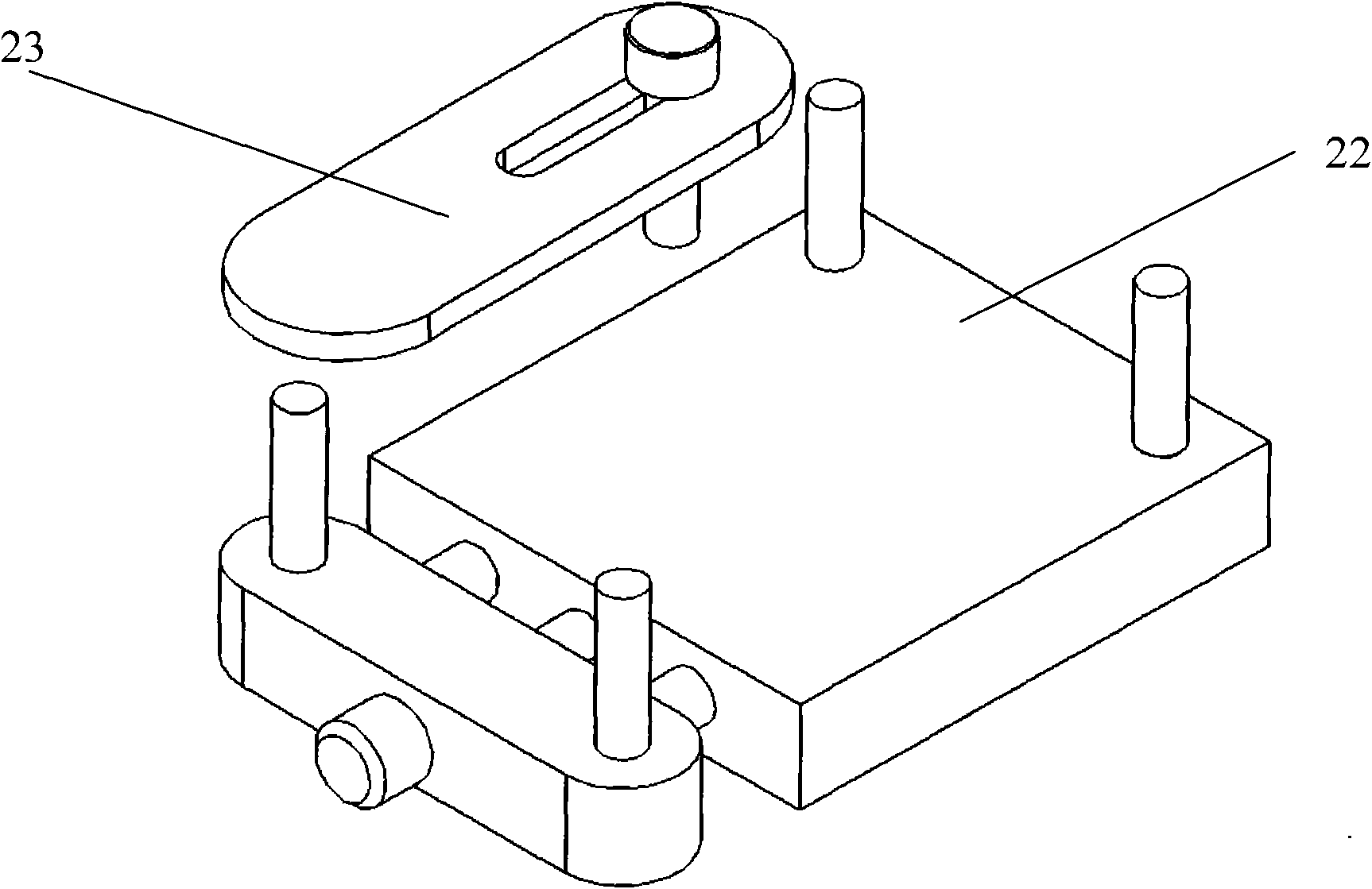

[0047] The rotating measuring table and its control part 2 include a rotating measuring table 21 and its driving mechanism and the first and second accessories 22 and 23. The first and second accessories 22 and 23 are arranged on the rotating measuring table 21. On the platform where the denture dental model is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com