Precision vibration mirror correction system and method

A correction system and precise technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of adverse effects of galvanometer correction, large calculation errors, etc., achieve stable mechanism, easy operation, and ensure measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

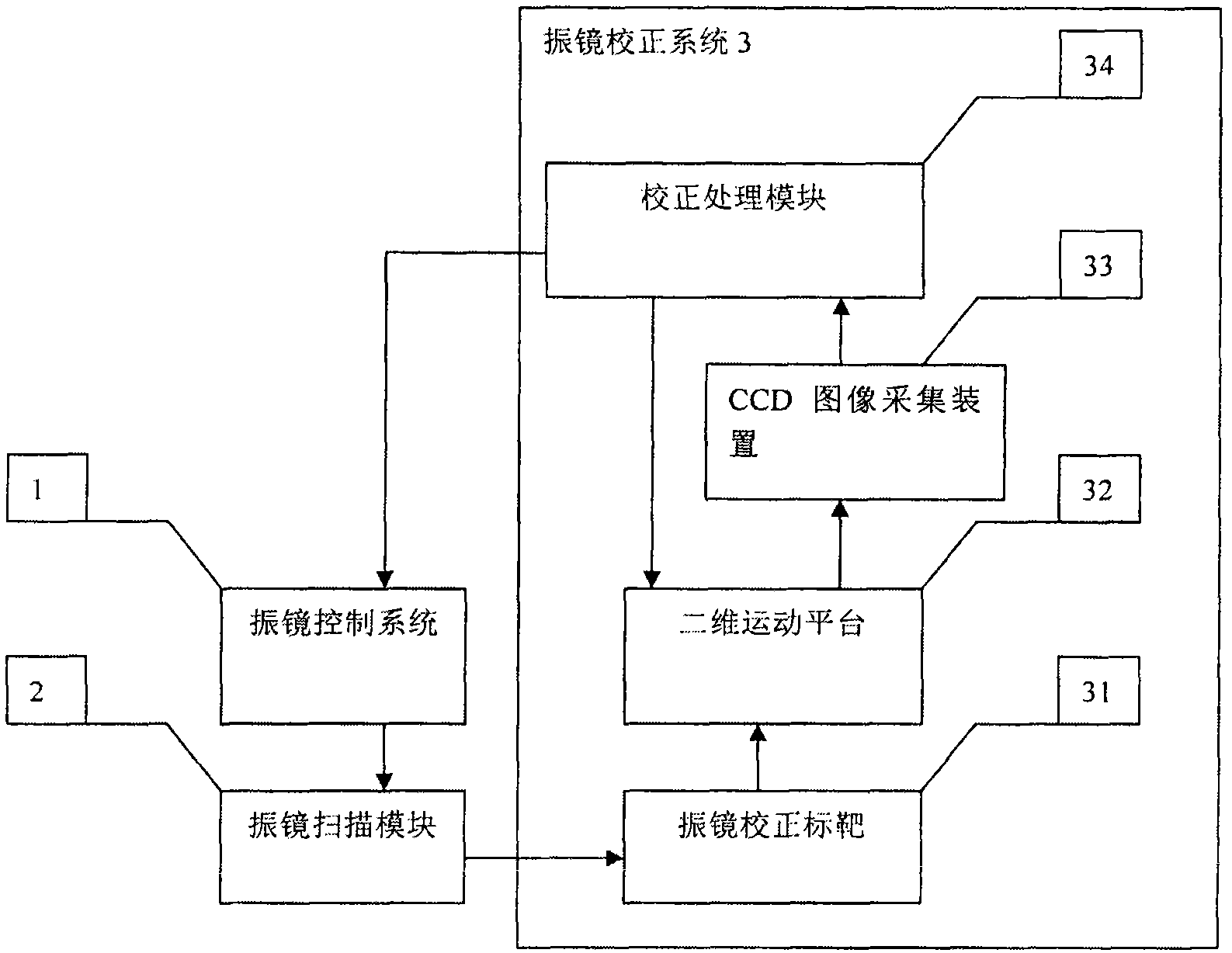

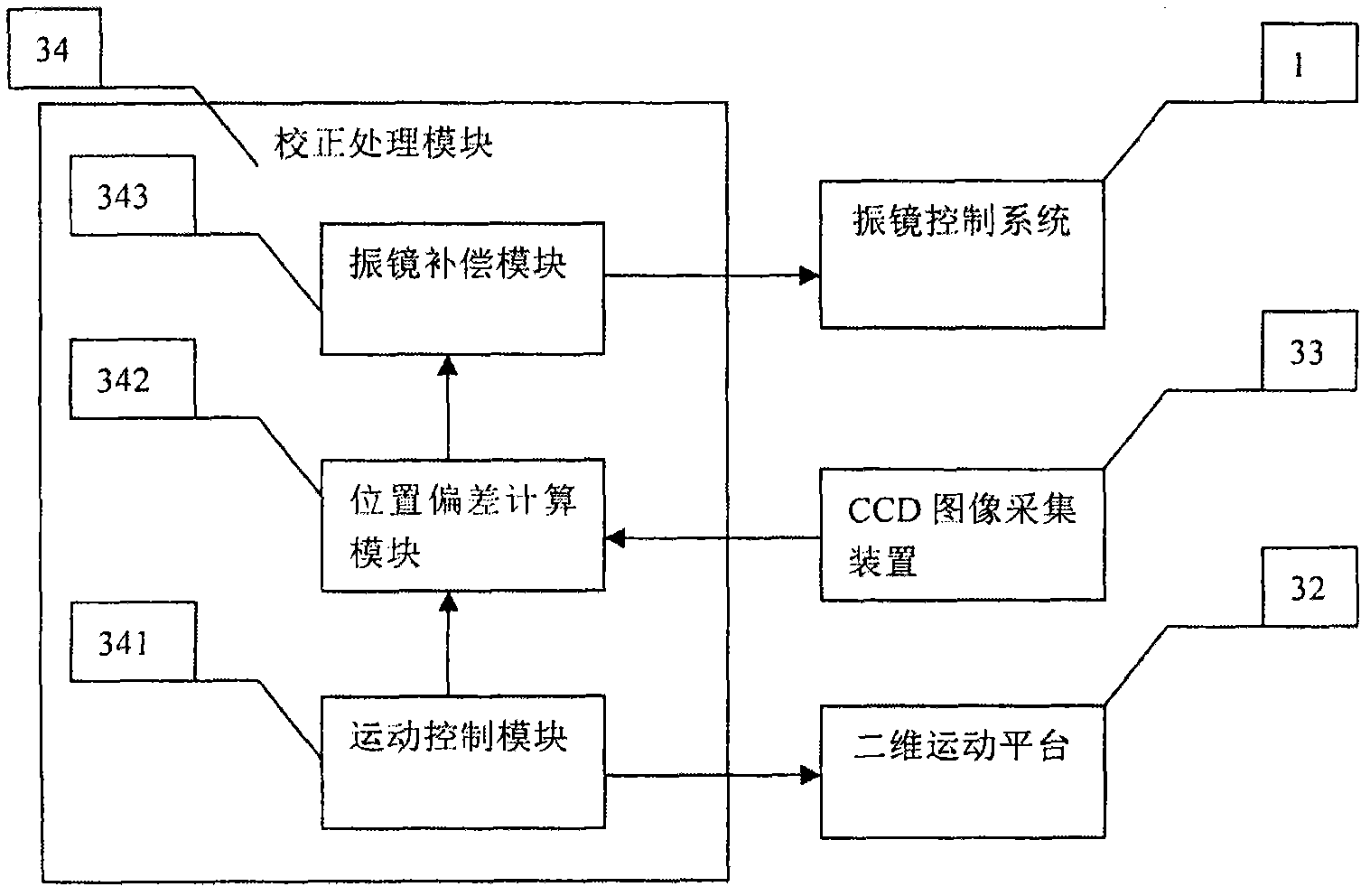

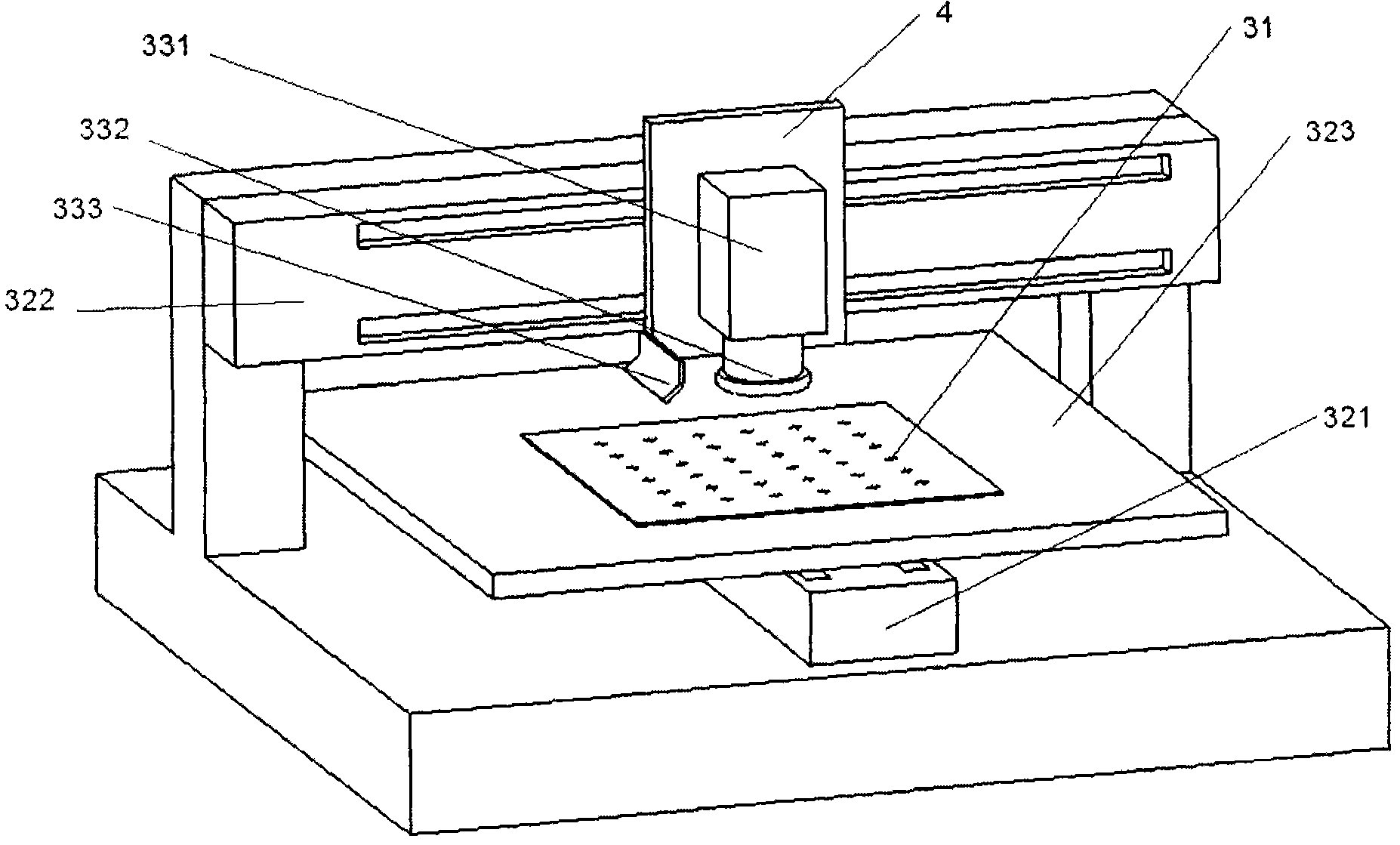

[0034] figure 1 Shown is an embodiment of the module structure of the precise galvanometer correction system of the present invention, image 3 Shown as figure 1 An embodiment of the assembly structure of the precision galvanometer correction system. Such as figure 1 with image 3 As shown, the galvanometer correction system 3 includes a galvanometer correction target 31, a two-dimensional motion platform 32, a CCD image acquisition device 33, and a correction processing module 34. The galvanometer correction system 3 is installed on the fixed base 4, and a two-dimensional motion platform 32 is provided at the bottom of the galvanometer correction target 31. The two-dimensional motion platform 32 includes a Y linear motor 321, an X linear motor 322 and a working platform. 323. The Y linear motor 321 is arranged in the Y direction in the plane coordinate system, the X linear motor 322 is arranged in the X direction and above the Y linear motor 321, and the working platform 323 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com