Manufacturing method of integral forging hook cylinder of hook bock assembly for minus 60 DEG C polar region drilling rig

An integral forging and manufacturing method technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve problems such as low temperature impact energy cannot be satisfied, non-destructive flaw detection pass rate is low, difficult to meet quality requirements, etc., to achieve no grinding process, good quality The effect of heat treatment manufacturability and high pass rate of non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

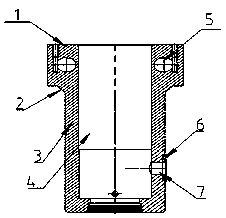

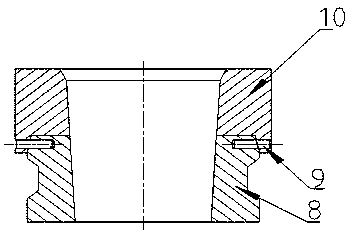

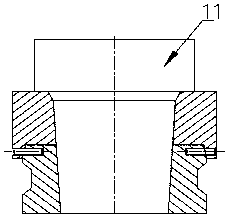

[0019] see Figure 1~Figure 3 Among them, the design and manufacture of a forged hook barrel (PSL2 grade) for the traveling block of an oil rig used in the polar low temperature (-60°C) environment. The forged hook barrel includes an upper square 1, a lower cylinder 3, and a cone 2 It is a transition part, with a stepped through hole 4 in the middle; there are two first pin holes 5 on the quadrilateral body 1, which are connected with the side plate of the traveling block through the pin shaft; the stepped through hole 4 is used to install the hook rod and the buffer spring set, load-bearing bearings, etc.; the cylinder 3 is provided with a backing plate 6 and a second pin hole 7, which is used to install a rotation positioning locking device, and the locking tongue in the locking device is locked through the second pin hole 7 Tighten the hook rod installed in the ladder through hole 4. The manufacturing process about the hook cylinder comprises the following steps:

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com