Shaft-mounted brake disc connecting device and vehicle adopting same

A connecting device and brake disc technology, applied in the direction of the brake disc, etc., can solve the problems of bolt failure, failure to improve the axial tilt of the bolt, and failure to effectively avoid shear force, etc., so as to avoid bolt failure and reduce driving safety accidents The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

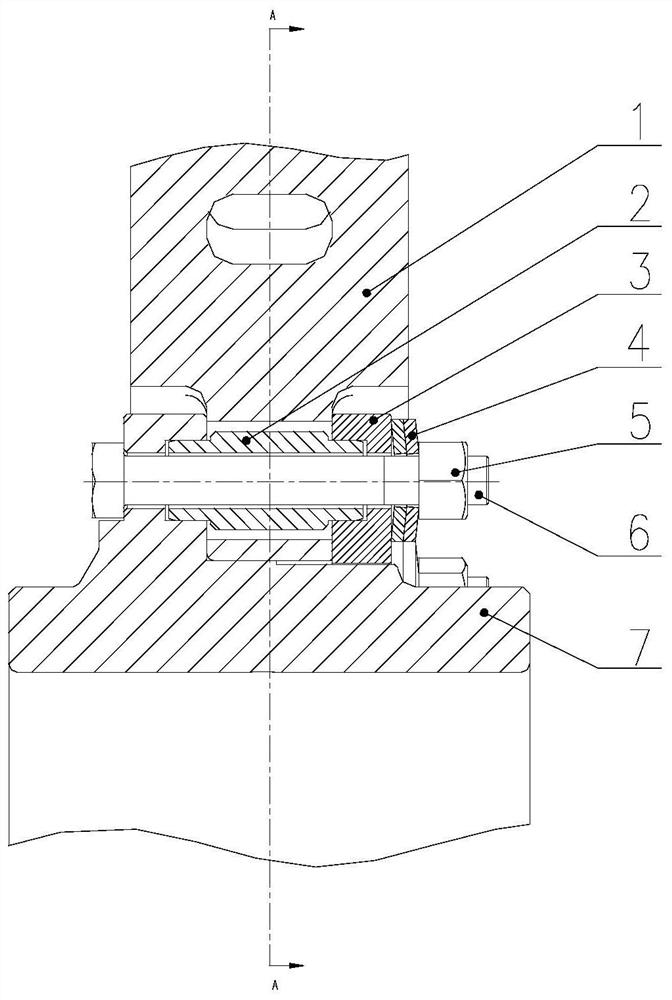

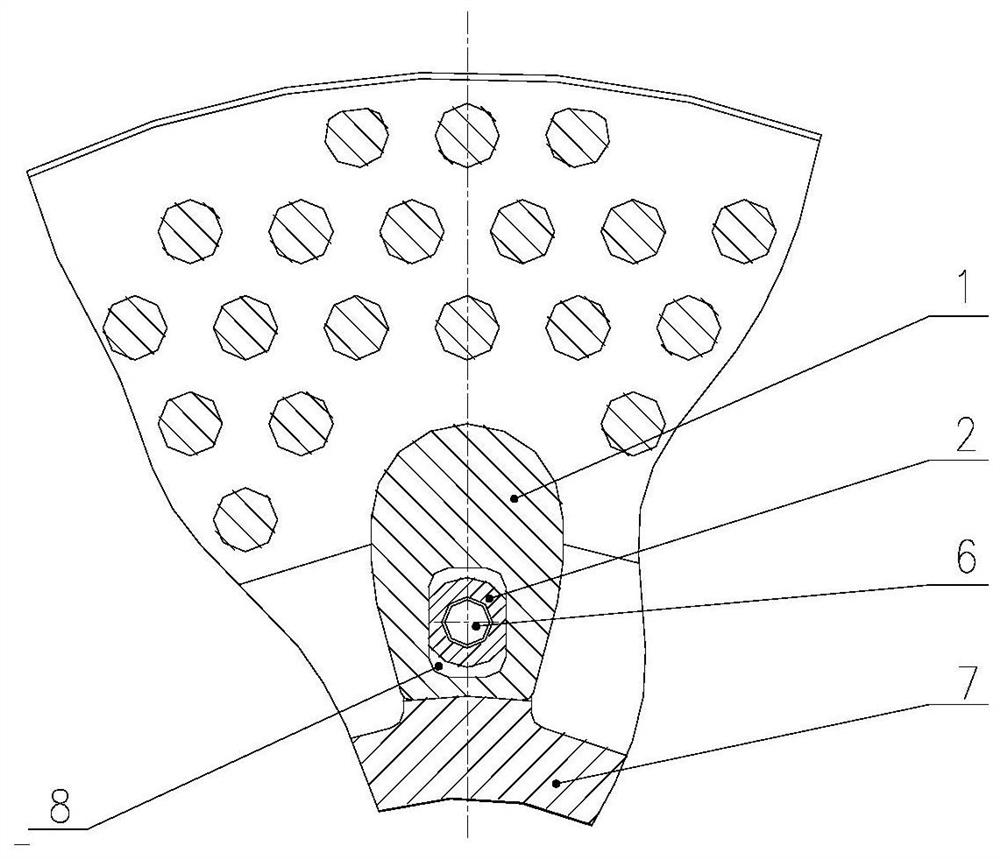

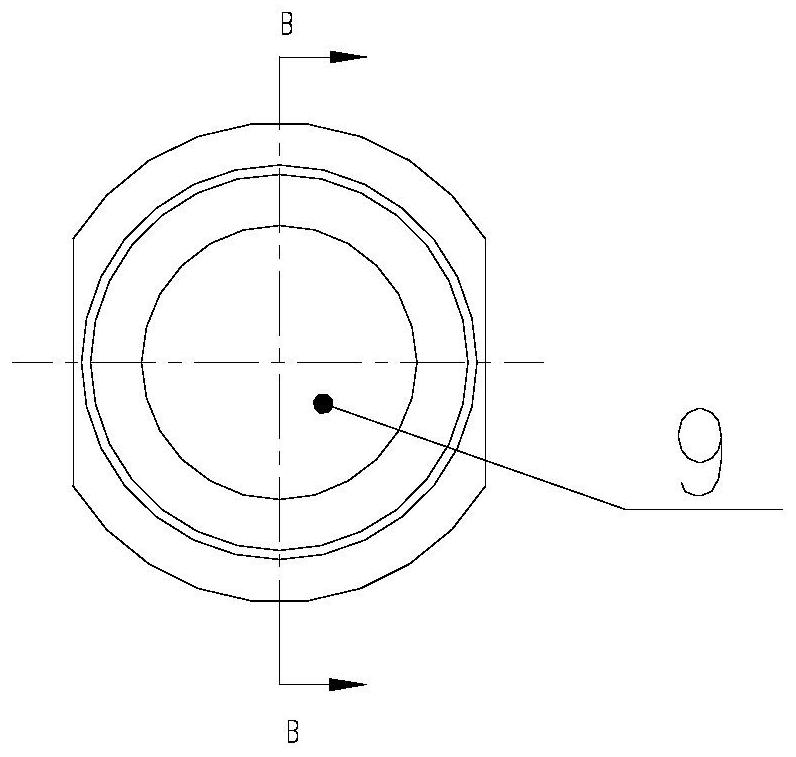

[0035] This embodiment provides a shaft brake disc connection device, such as Figure 1-8As shown, including the disc body 1, the hollow pin 2, the pressure plate 3, butterfly spacer 4, the locking nut 5, the bolt 6, and the hub 7. Each of the disk bodies 1 and the plate hub 7 have a connecting portion having a mounting hole on each of the connecting portions, and the pressure plate 3 also has a mounting hole such as a circumferential distribution. The mounting holes include bolt holes and hollow pin holes, and the plurality of hollow pin holes are arranged with bolt holes. The hollow pin holes 8 on the disk body 1 are a lumbar through hole concentric with the bolt holes on the disc connection, and the hollow pin holes on the press plate 3 and the hub 7 are inserted with the bolt holes. The hollow pin 2 is a concentric stepped structure, and the center has through through holes, and both ends are cylindrical structures, and the central part is a lumbar structure.

[0036] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com