Micro-channel jet radiator

A technology of tiny channels and heat sinks, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of weakened injection effect, reduced injection effect, and reduced local heat dissipation coefficient, so as to ensure impact heat transfer Effect, enhanced heat dissipation effect, effect of ensuring independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

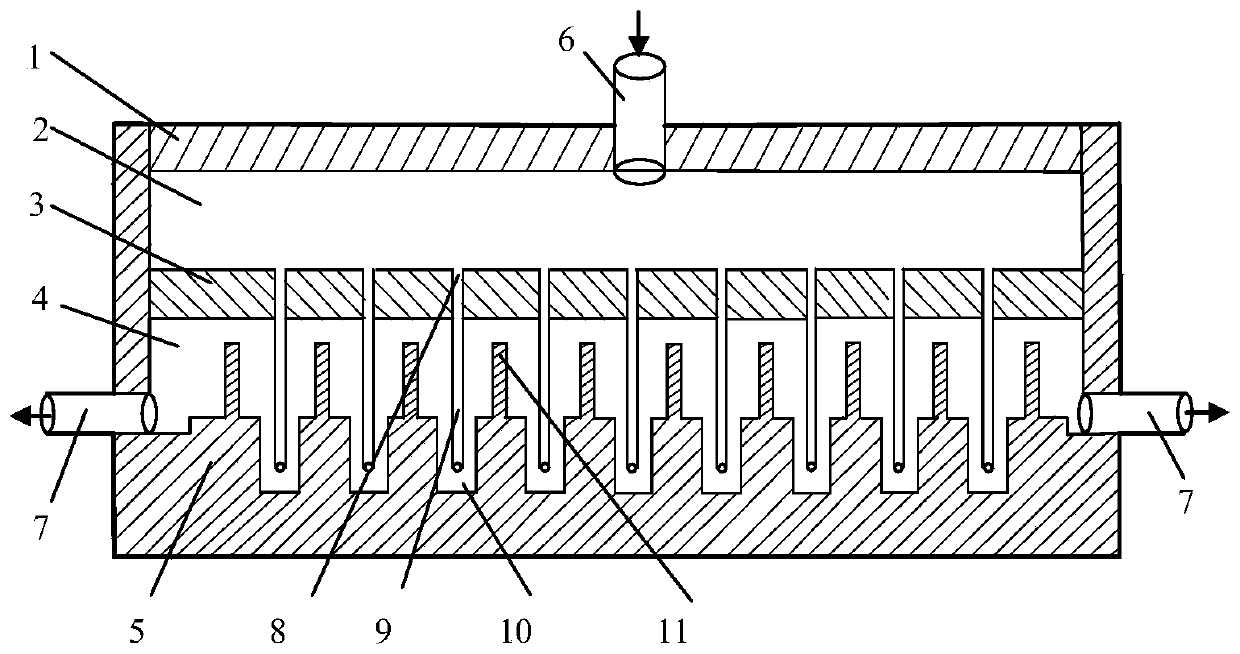

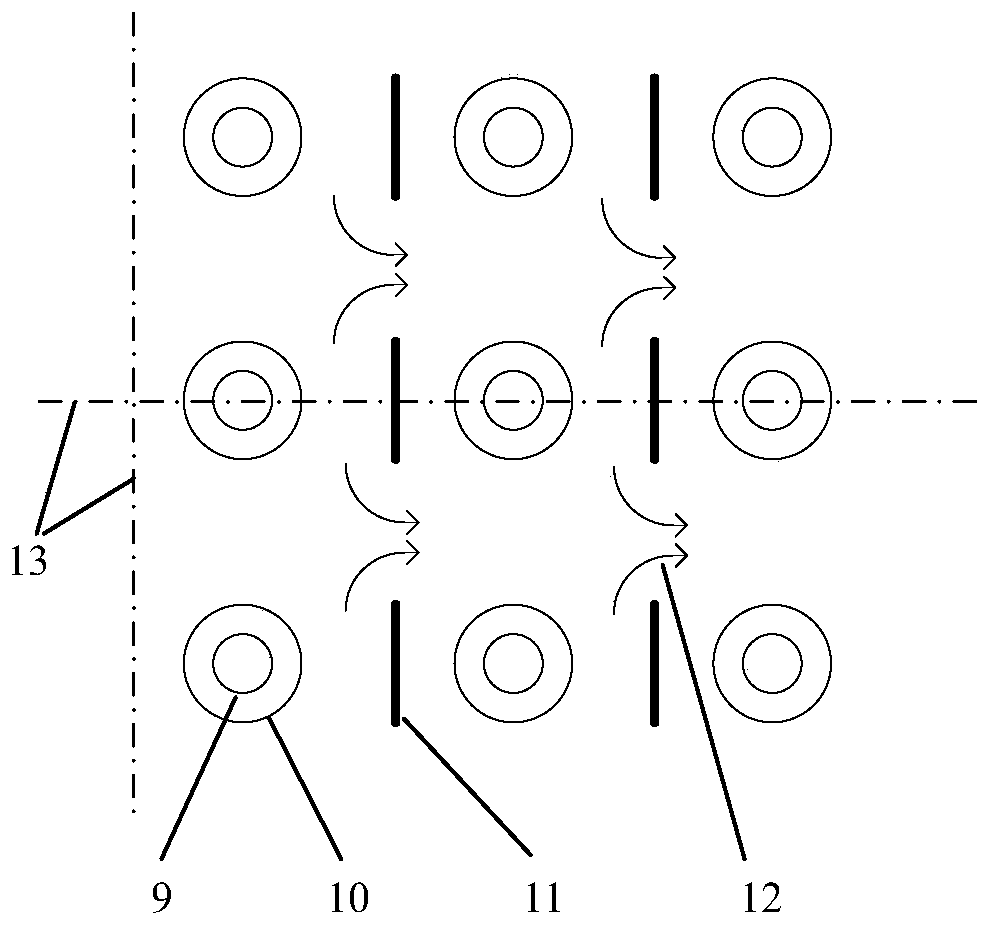

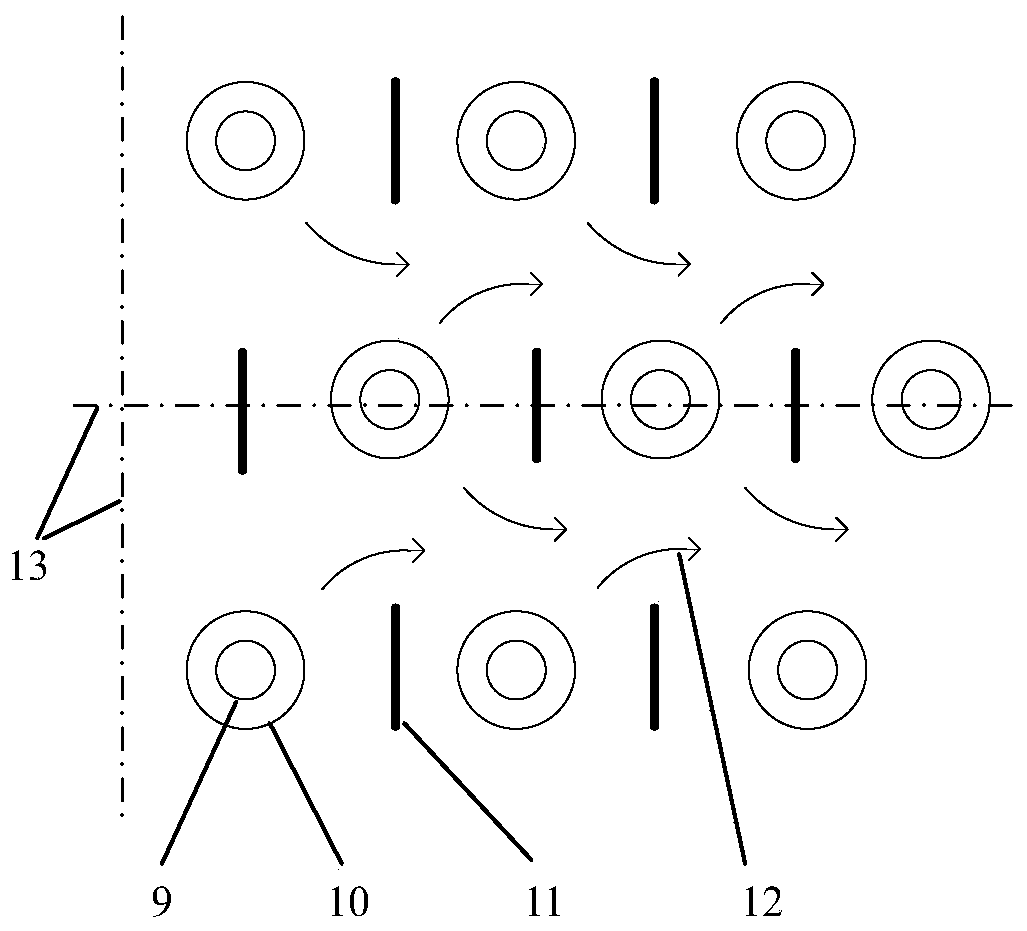

[0024] see figure 1 and figure 2 In this embodiment, the micro-channel jet radiator is provided with a cover plate 1 on the heat-conducting substrate 5 to form a box-shaped body with an inner cavity, and a partition 3 is horizontally arranged in the inner cavity, and the inner cavity is divided into an upper part by the partition 3 The liquid inlet chamber 2 and the lower liquid outlet chamber 4, the fluid working medium inlet 6 are arranged on the cover plate 1, and the fluid working medium outlet 7 are arranged on both sides of the heat conduction substrate 5; jet holes 8 are distributed on the partition 3.

[0025] In the lower liquid outlet chamber 4, pits 10 are distributed on the surface of the heat-conducting substrate 5, and the pits 10 correspond to the jet holes 8 on the partition 3 in the vertical direction; Jet tube 9, the upper end surface of jet tube 9 is not higher than the upper surface of dividing plate 3, and the lower end of jet tube 9 hangs in the pit 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com