Heat treatment process for 200MW or lower large size rotor

A rotor and process technology, applied in the field of heat treatment of large rotors, can solve the problems of 200MW large rotors with large cross-section, large difference in step hardness, and low performance of large rotors, and achieve the effects of avoiding the risk of cracking, heavy weight, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

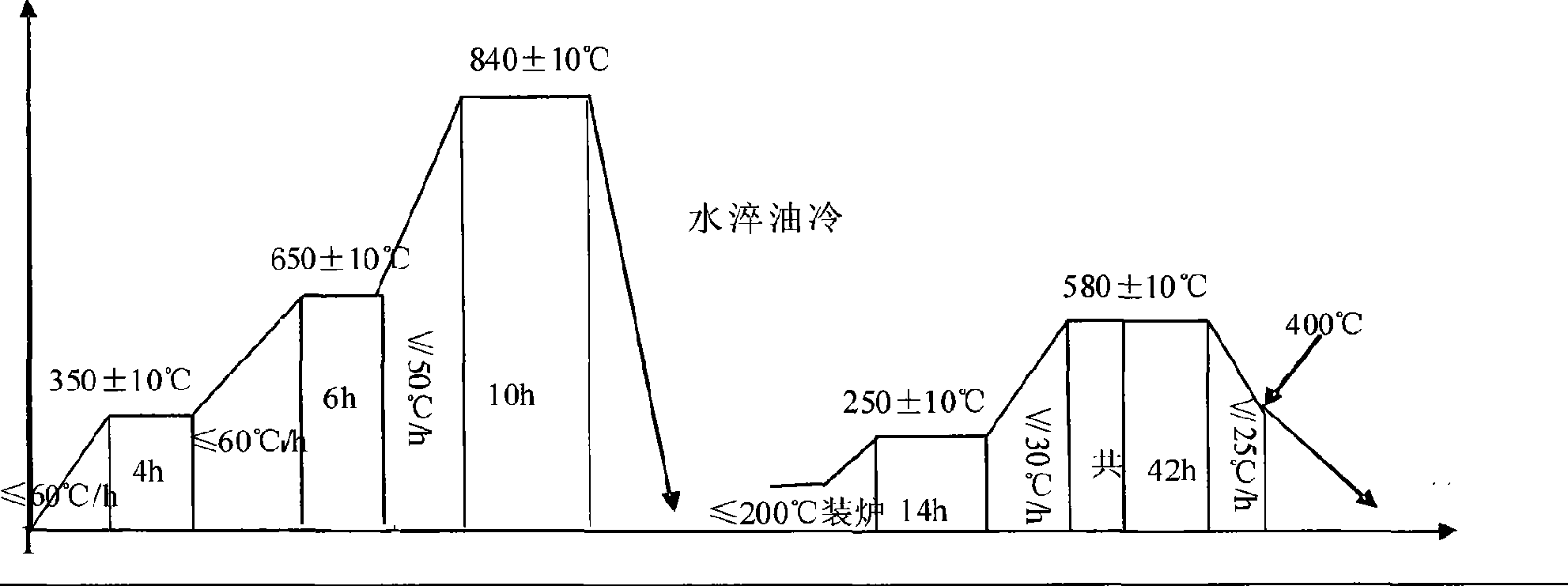

[0026] Such as figure 1 , 2 Shown: The large rotor heat treatment process of 200MW and below adopts the cooling method of water quenching and oil cooling to control the quenching temperature and tempering temperature; strictly control the temperature of outlet water and oil, the time of water quenching, and the time of oil cooling; the time of water quenching and oil cooling is directly related to The hardenability of this material is good, and the most ideal structure required by the material is tempered upper bainite. It is advisable to increase the water temperature appropriately, reduce the cooling rate in the water, reduce the thermal stress, and minimize the stress during quenching. deformation and cracking tendency,

[0027] The implementation of the heat treatment process plan for the production of large rotors of 200MW and below, because the weight of the parts reached 41t, which exceeded the load-bearing requirements of the originally designed tooling,

[0028] Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com