High-performance mineral-filled PC/ABS alloy material and preparation method thereof

An alloy material and high-performance technology, applied in the field of high-performance mineral-filled PC/ABS alloy material and its preparation, can solve the problems of restricting development, decrease in impact strength, decrease in impact toughness of materials, etc., and achieve improved modulus and good impact toughness. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

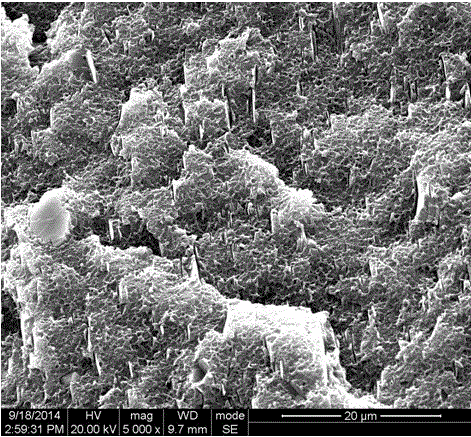

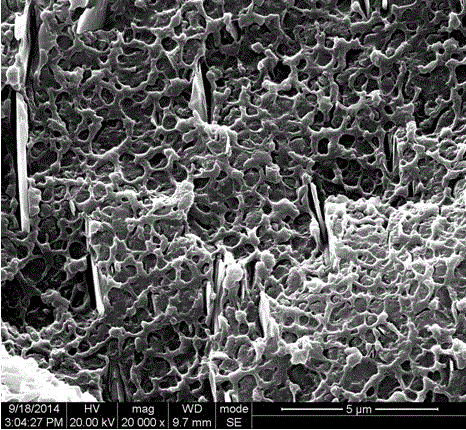

Image

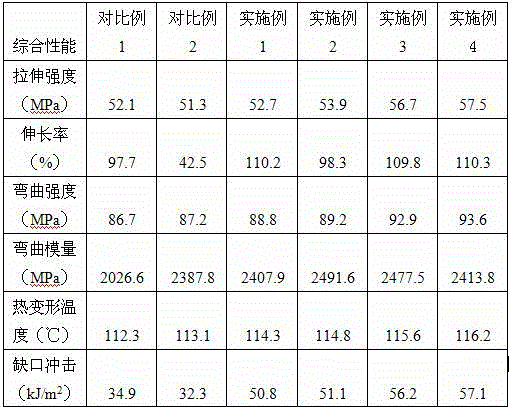

Examples

Embodiment 1

[0059] Bisphenol A polycarbonate 60.1 parts

[0060] Masterbatch 36 parts

[0061] Methyl methacrylate-butadiene-styrene copolymer 2 parts

[0062] 1 part high-glue powder

[0063] Ciba 168 0.1 parts

[0064] Ciba 1076 0.1 parts

[0065] Pentaerythritol stearate PETS 0.3 parts

[0066] Silane coupling agent KH550 0.4 parts;

[0067] Wherein, the masterbatch is a mixture of talcum powder, KH550 silane coupling agent and acrylonitrile-butadiene-styrene copolymer in a mass ratio of 45:1:45.

[0068] The preparation method of high performance mineral filled PC / ABS alloy material of the present invention comprises the following steps:

[0069] (1) Weigh the raw materials according to the above weight ratio;

[0070] (2) One-time blending: first spray the coupling agent on the talc powder, and then mix it evenly with a mixer to obtain the talc powder treated with the coupling agent; then blend the ABS and the talc powder treated with the coupling agent in proportion , extrus...

Embodiment 2

[0073] Bisphenol A polycarbonate 66.1 parts

[0074] Masterbatch 30 parts

[0075] Methyl methacrylate-butadiene-styrene copolymer 2 parts

[0076] 1 part high-glue powder

[0077] Ciba 168 0.1 parts

[0078] Ciba 1076 0.1 parts

[0079] Pentaerythritol stearate PETS 0.3 parts

[0080] Silane coupling agent KH550 0.4 parts;

[0081] Wherein, the masterbatch is a mixture of talcum powder, KH550 silane coupling agent and acrylonitrile-butadiene-styrene copolymer in a mass ratio of 50:1:50.

[0082] The rest of this embodiment is the same as Embodiment 1, and will not be repeated here.

Embodiment 3

[0084] Bisphenol A polycarbonate 76.1 parts

[0085] Masterbatch 20 parts

[0086] Methyl methacrylate-butadiene-styrene copolymer 2 parts

[0087] 1 part high-glue powder

[0088] Ciba 168 0.1 parts

[0089] Ciba 1076 0.1 parts

[0090] Pentaerythritol stearate PETS 0.3 parts

[0091] Silane coupling agent KH550 0.4 parts;

[0092] Wherein, the masterbatch is a mixture of talc powder, KH550 silane coupling agent and acrylonitrile-butadiene-styrene copolymer in a mass ratio of 55:3:55.

[0093] The rest of this embodiment is the same as Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com