Pipe shell type heat exchanger and baffle

A heat exchanger and deflector technology, applied in the field of shell-side deflectors and spiral deflectors of shell-and-tube heat exchangers, can solve problems such as reducing heat exchange effect, and achieve improved heat exchange efficiency, low resistance, The effect of angle optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

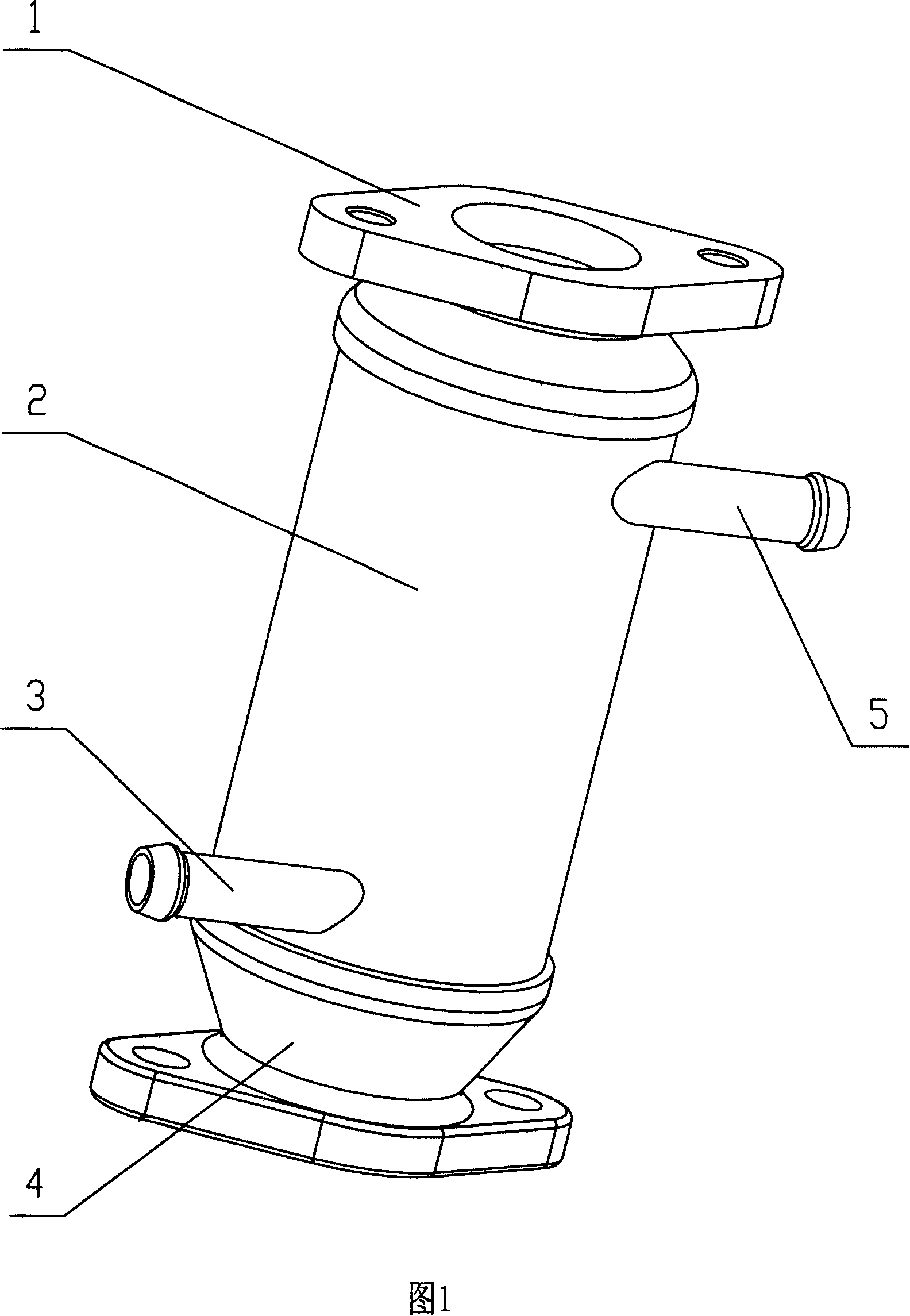

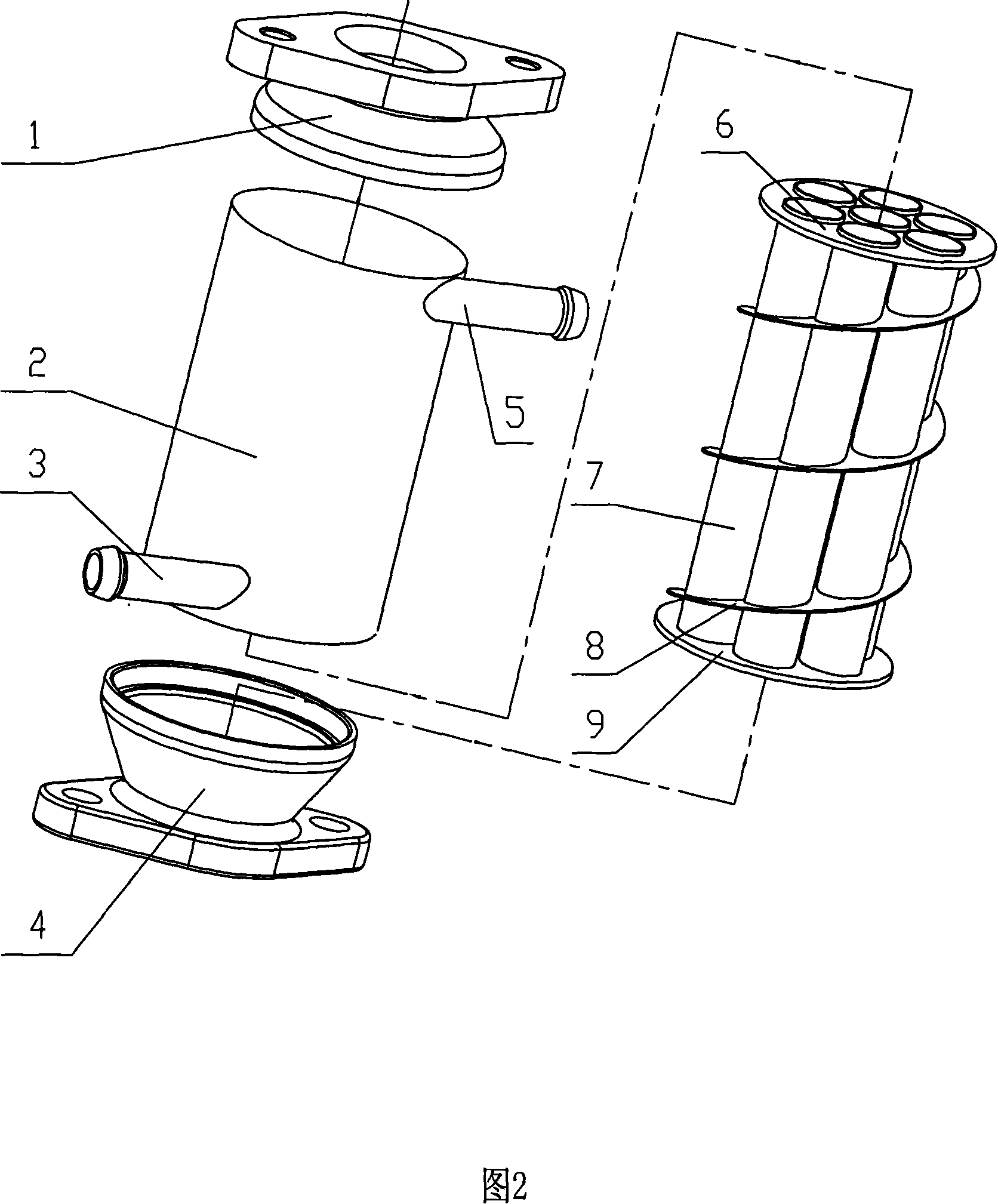

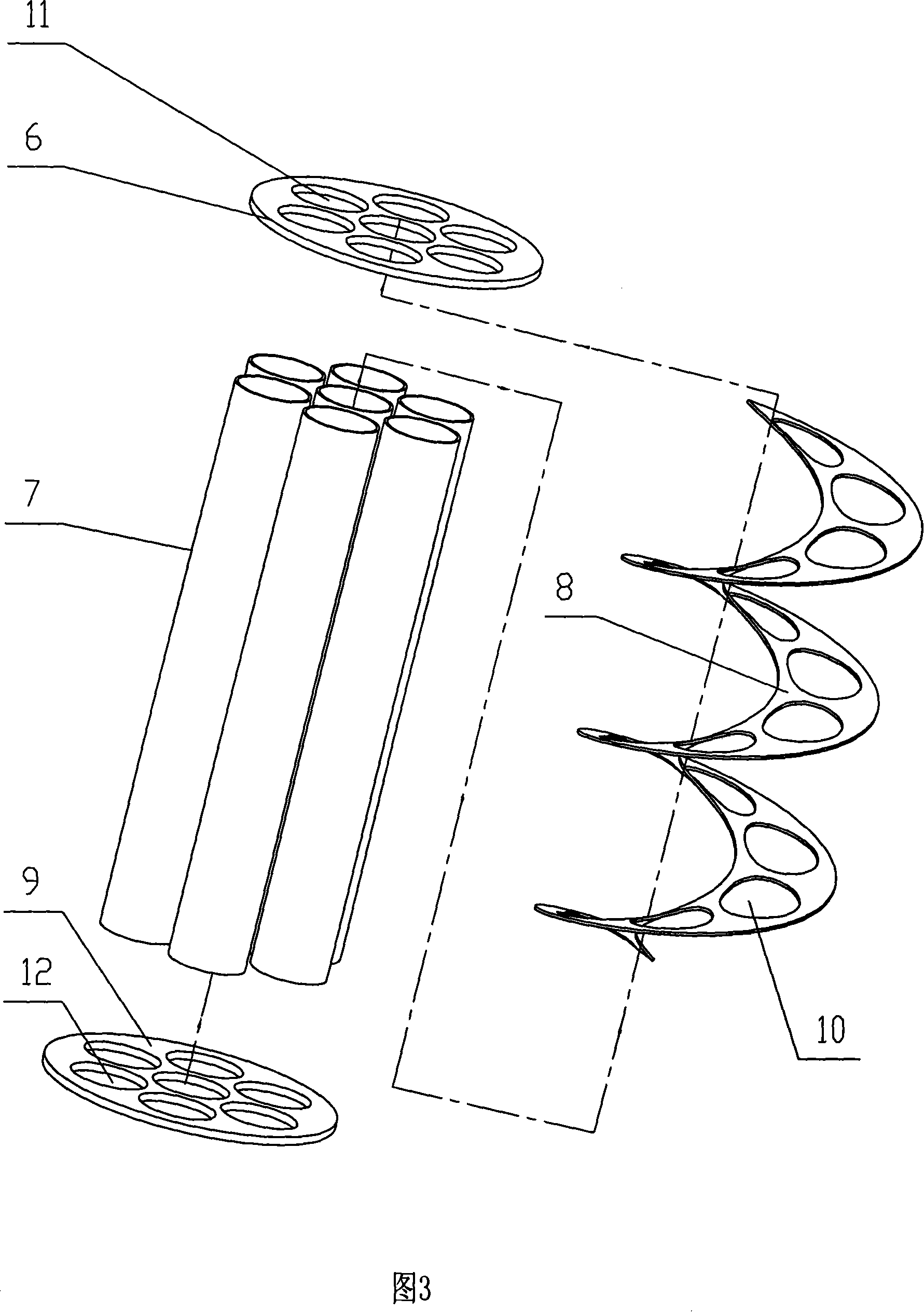

[0021] Referring to Figures 1-3, the shell-and-tube heat exchanger consists of a shell 2 and a core, where the shell 2 includes a heat medium inlet flange 1, a shell 2, a cold medium inlet pipe 3, a heat medium outlet flange 4 and Cold medium outlet pipe 5. The core body includes a heat medium inlet end plate 6, a tube bundle 7, a spiral deflector 8 and a heat medium outlet end plate 9; the tube bundle 7 runs through a through hole 10, and the two ends are respectively positioned on the heat medium inlet end plate 6 and the heat medium outlet end plate 9 on the through holes 11,12 offered. When the heat exchanger is working, the hot side medium flows out from the heat medium inlet flange 1 through the tube bundle and then flows out from the heat medium outlet flange 4, and the cold medium enters the shell 2 from the cold medium inlet pipe 3, and passes through the shells by the spiral deflector 8 and the spiral channel formed by the tube bundle, the cold medium outlet pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com