High-speed wheel-rail relation reliability test bed

A wheel-rail relationship and reliability technology, applied in the direction of railway vehicle testing, etc., can solve the problems of difficult wheel-rail relationship reliability test and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention is described in detail below in conjunction with accompanying drawing:

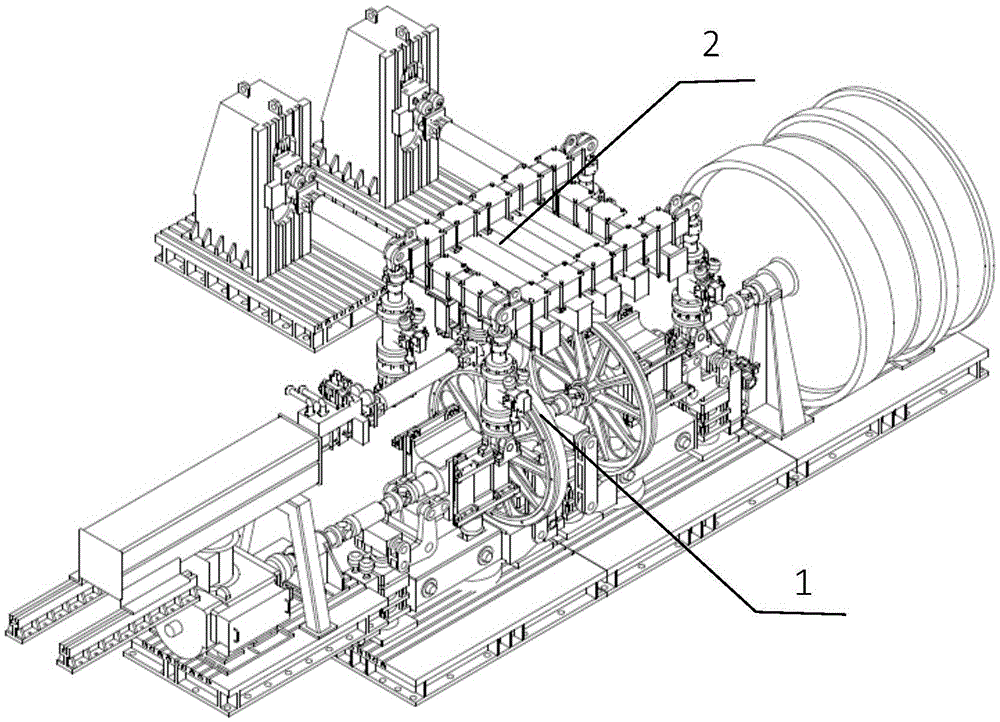

[0067] The track wheel motion device and power bogie simulation loading frame included in the high-speed wheel-rail relationship reliability test bench can accurately simulate the radial and axial loads and the impact of the track on the wheel set in the actual working conditions of the track train wheel set And the motion state under various motion conditions, truly reproduce the vibration of the rail vehicle wheel rail during operation, thus ensuring the correctness and authenticity of the test results of the reliability parameter test results of the high speed wheel rail relationship of the high speed train.

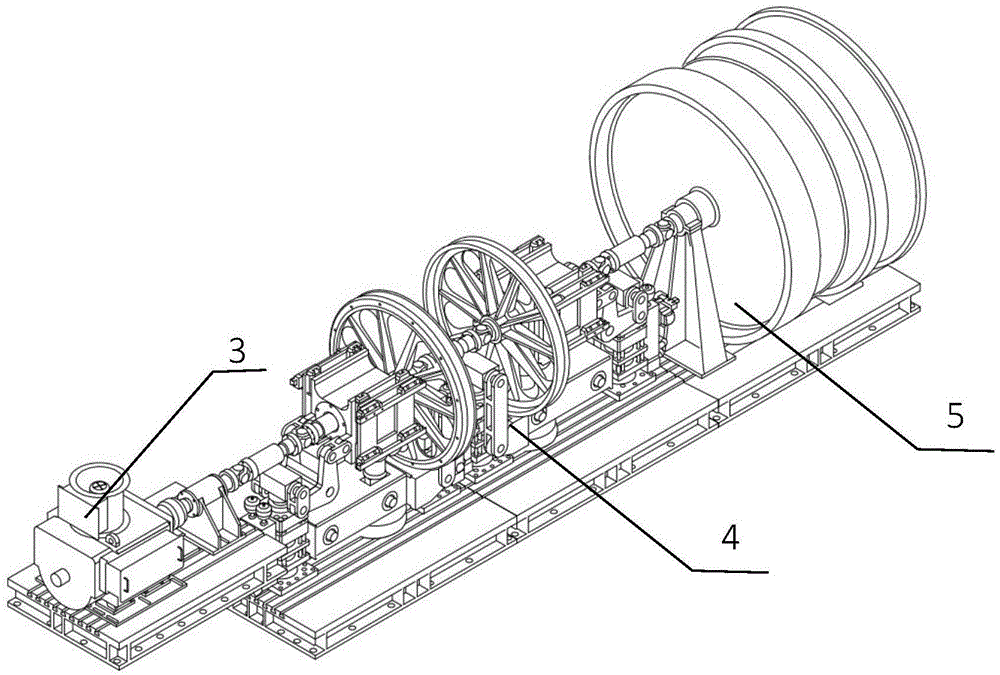

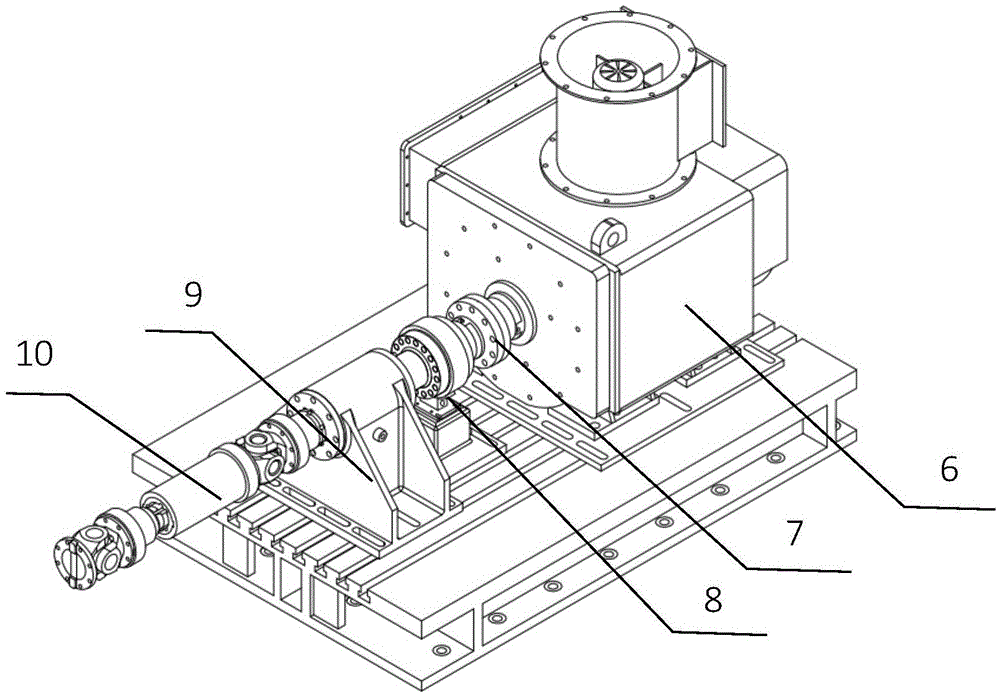

[0068] refer to figure 1 , figure 2 , Figure 24 , The high-speed wheel-rail relationship reliability test bench includes a track wheel motion device 1 and a power bogie simulation loading frame 2. The orbital wheel movement device 1 includes a frequency modulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com