Patents

Literature

31results about How to "Good test foundation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-speed electric multiple unit axle box bearing three-degree-of-freedom dynamic load reliability test platform

The invention discloses a high-speed electric multiple unit axle box bearing three-degree-of-freedom dynamic load reliability test platform and aims to overcome a problem that an axle box bearing reliability test can be not carried out in a practical operation. The test platform comprises a torque detection testing device and an axle box bearing reliability test device. The torque detection testing device is connected with the axle box bearing reliability test device through a cross shaft type universal shaft coupler. The axle box bearing reliability test device comprises a simulated frame side beam test device, a three-degree-of-freedom vibration simulation test device and a shaft assembly for an axle box bearing test. The three-degree-of-freedom vibration simulation test device comprises a vibration T type beam and a lateral actuator. The shaft assembly for the axle box bearing test is fixed on the vibration T type beam through bolts. The simulated frame side beam test device and the three-degree-of-freedom vibration simulation test device are placed in a parallel way. The parallel distance of the vibration T type beam in the three-degree-of-freedom vibration simulation test device and a simulated frame side beam supporting platform in the simulated frame side beam test device is 20 mm to 40 mm.

Owner:JILIN UNIV

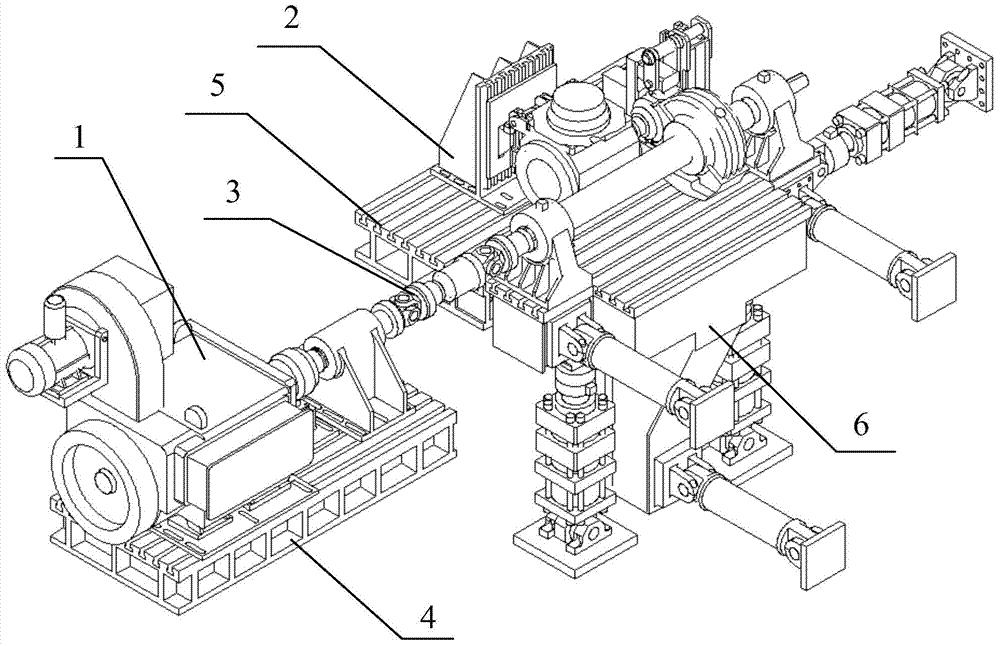

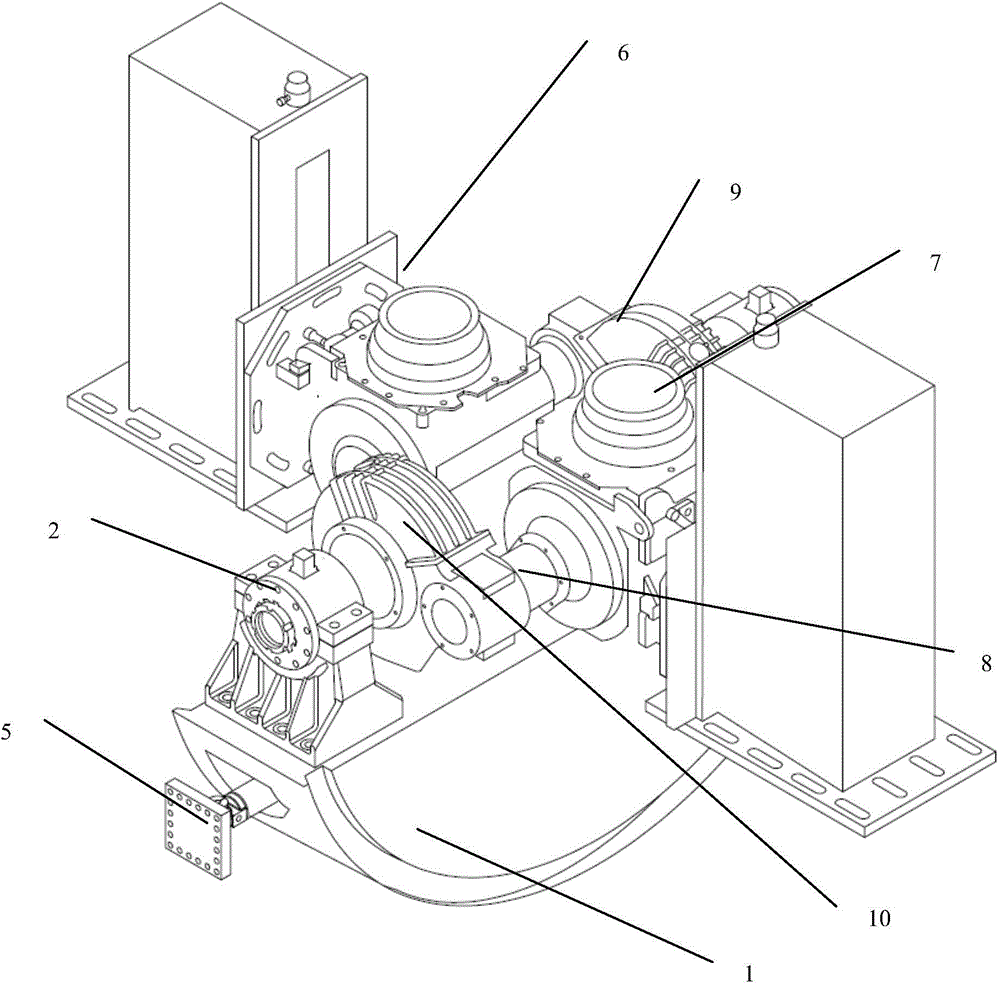

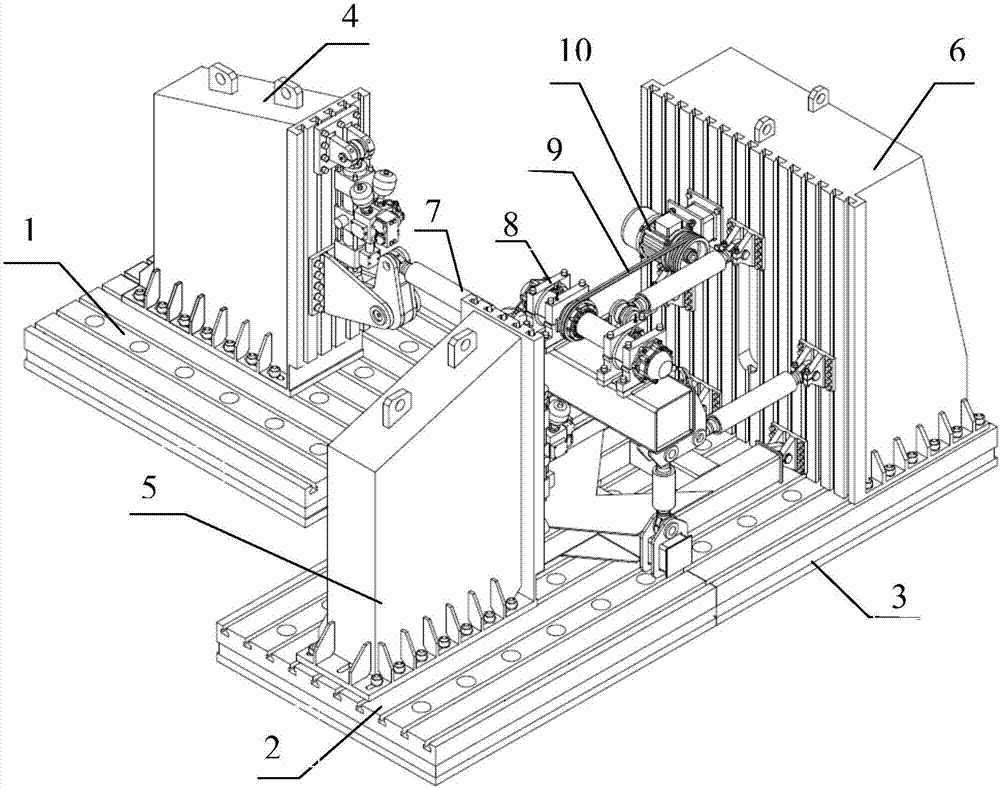

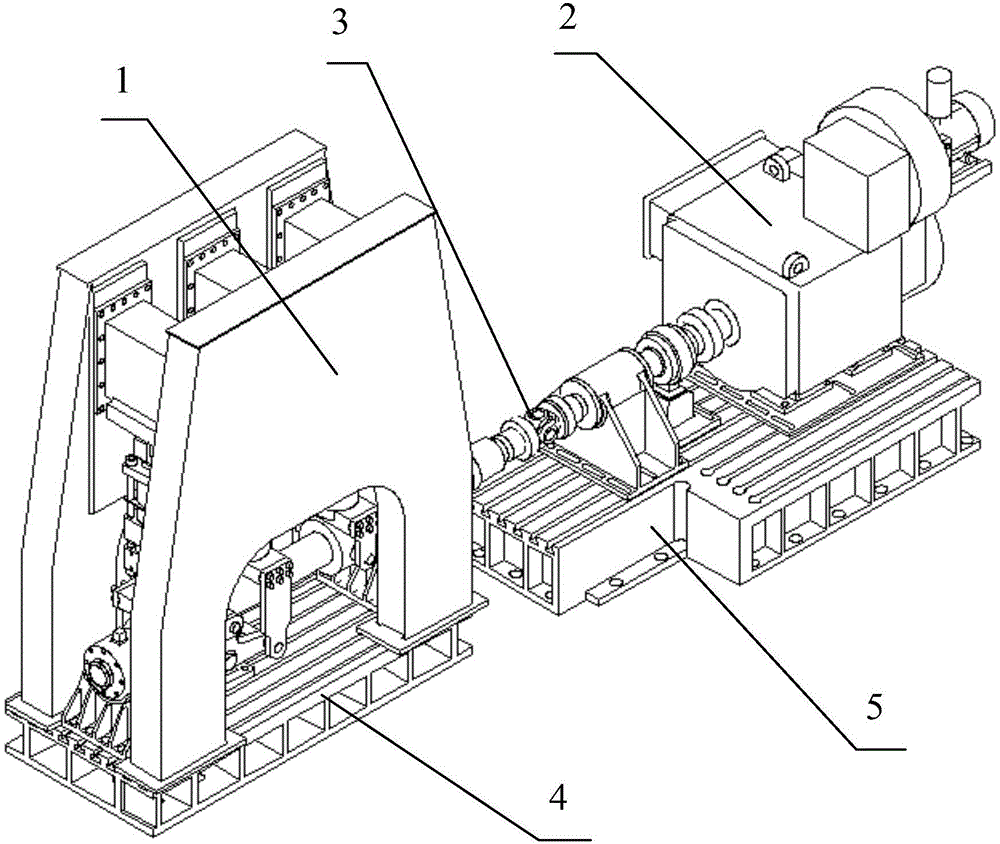

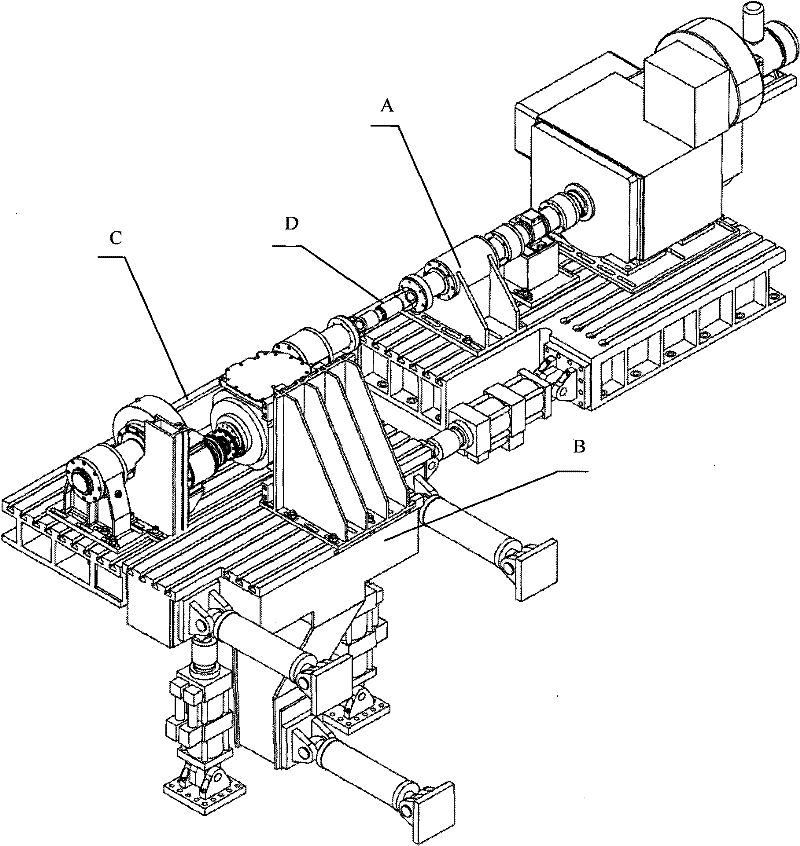

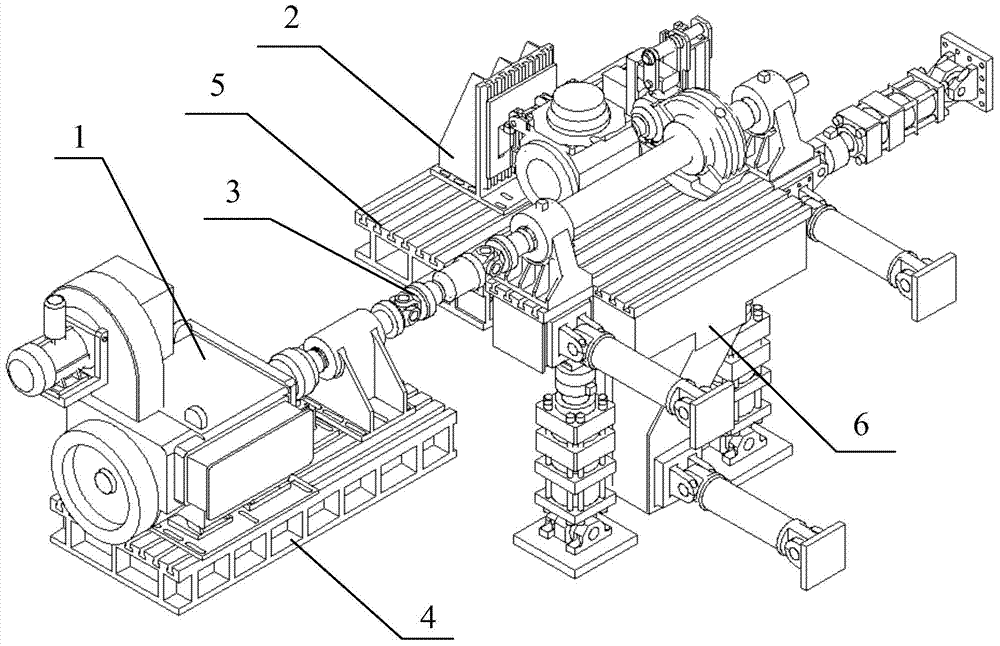

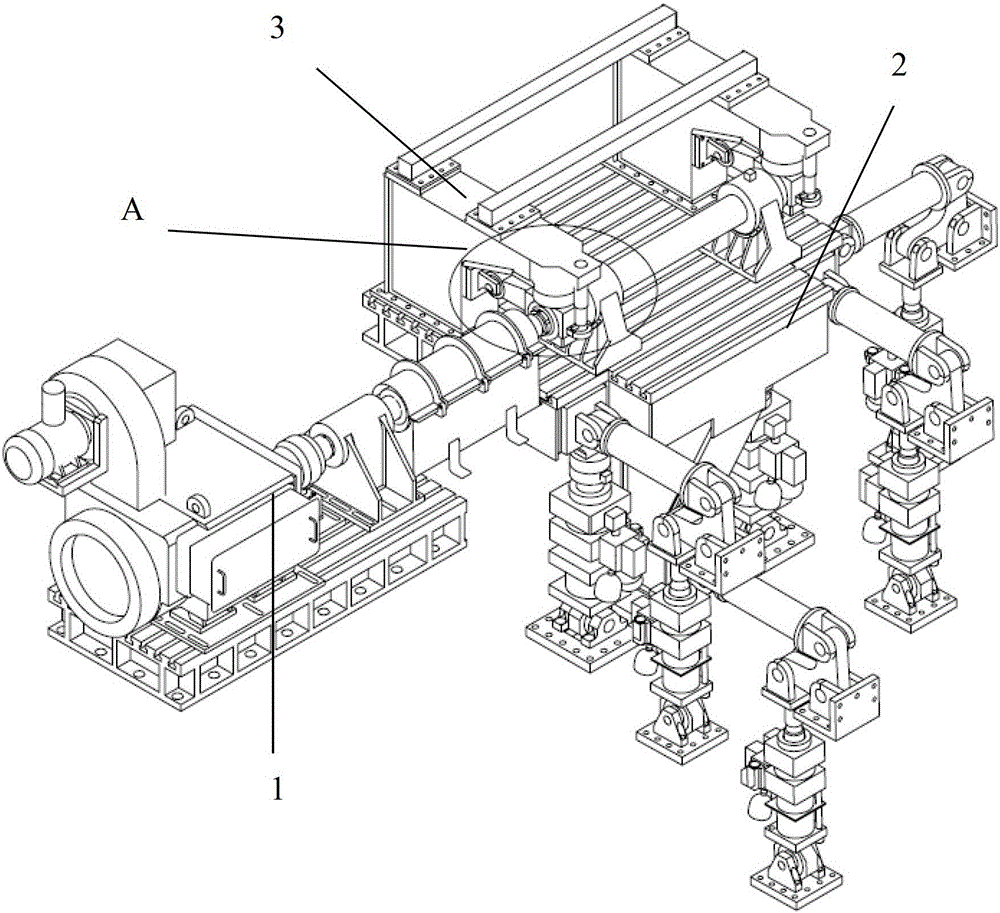

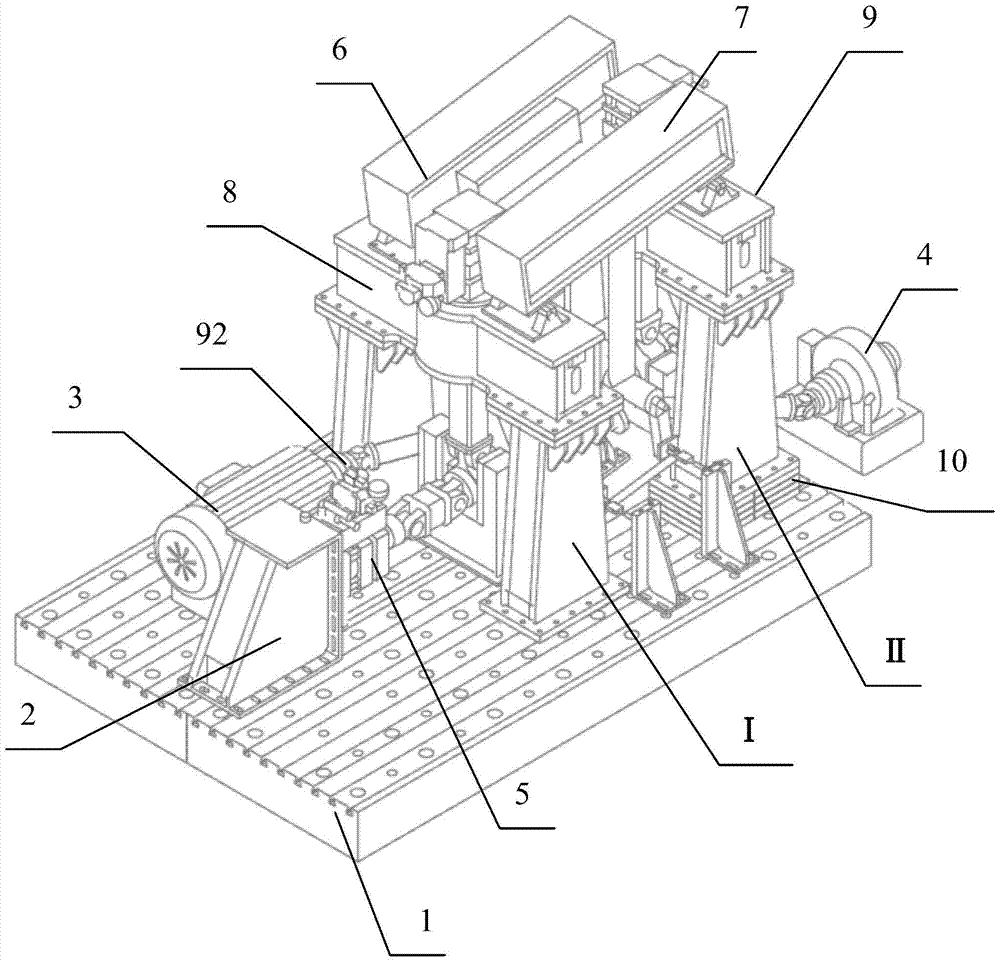

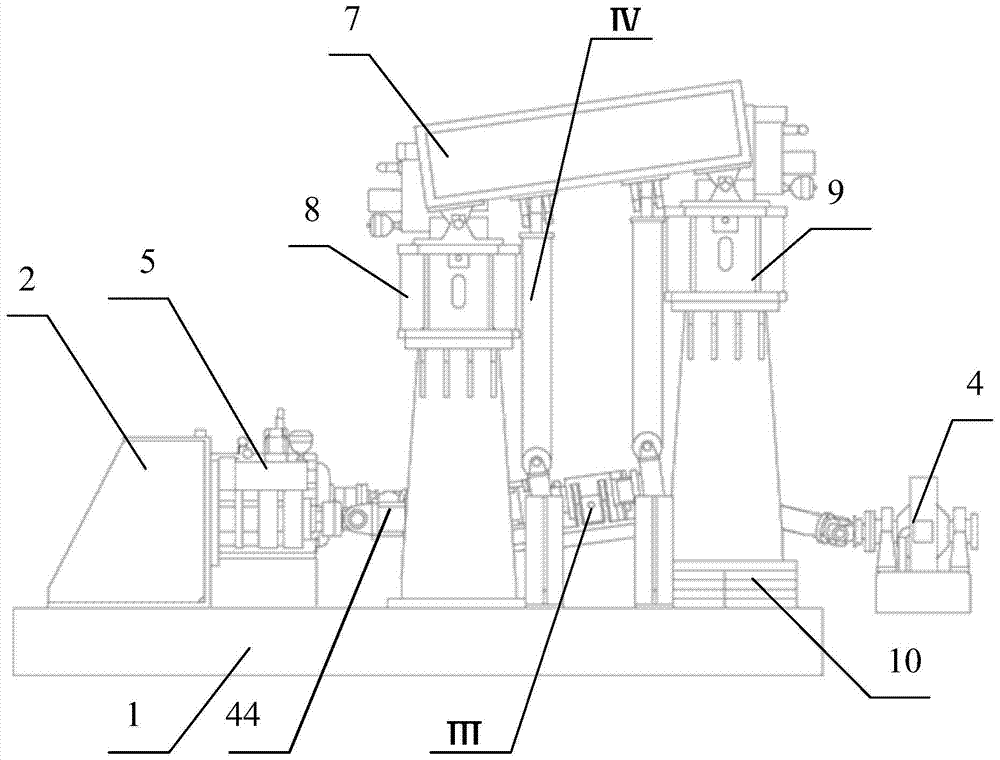

High-speed train transmission system assembly reliability test bed

InactiveCN102095578ATruly reflect the status of fatigue damageSimulate Vibration SituationsGearboxesMachine gearing/transmission testingThree degrees of freedomCoupling

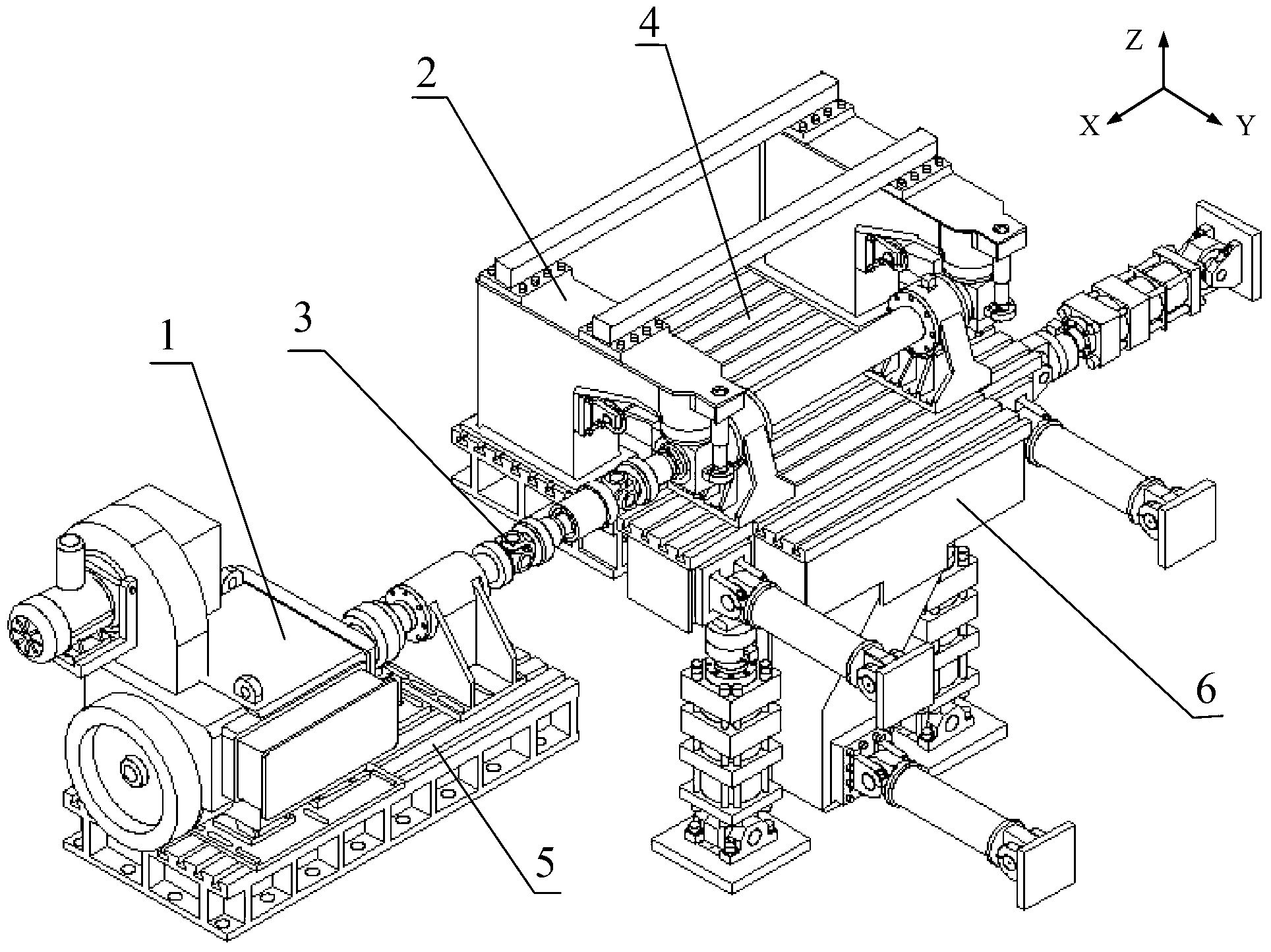

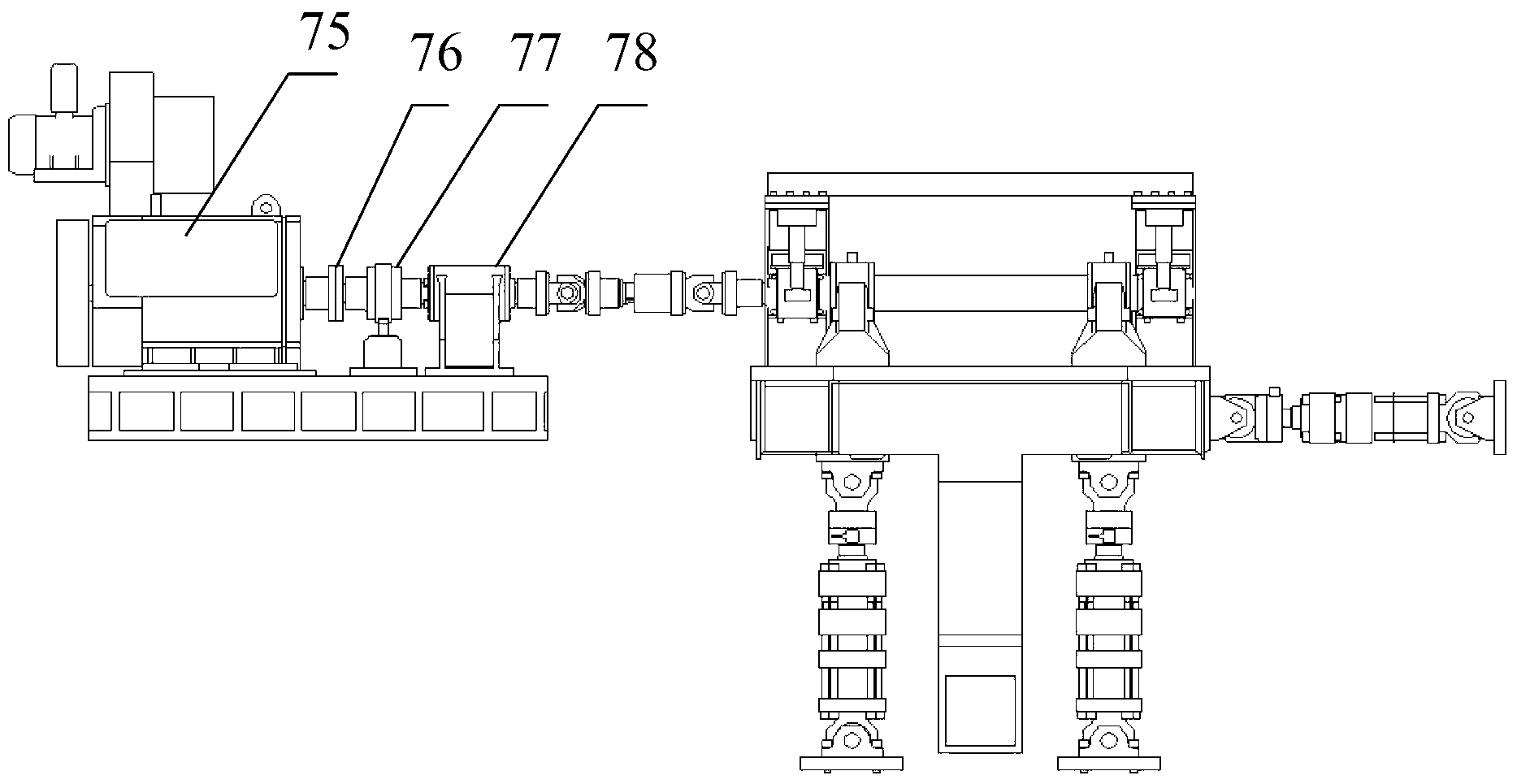

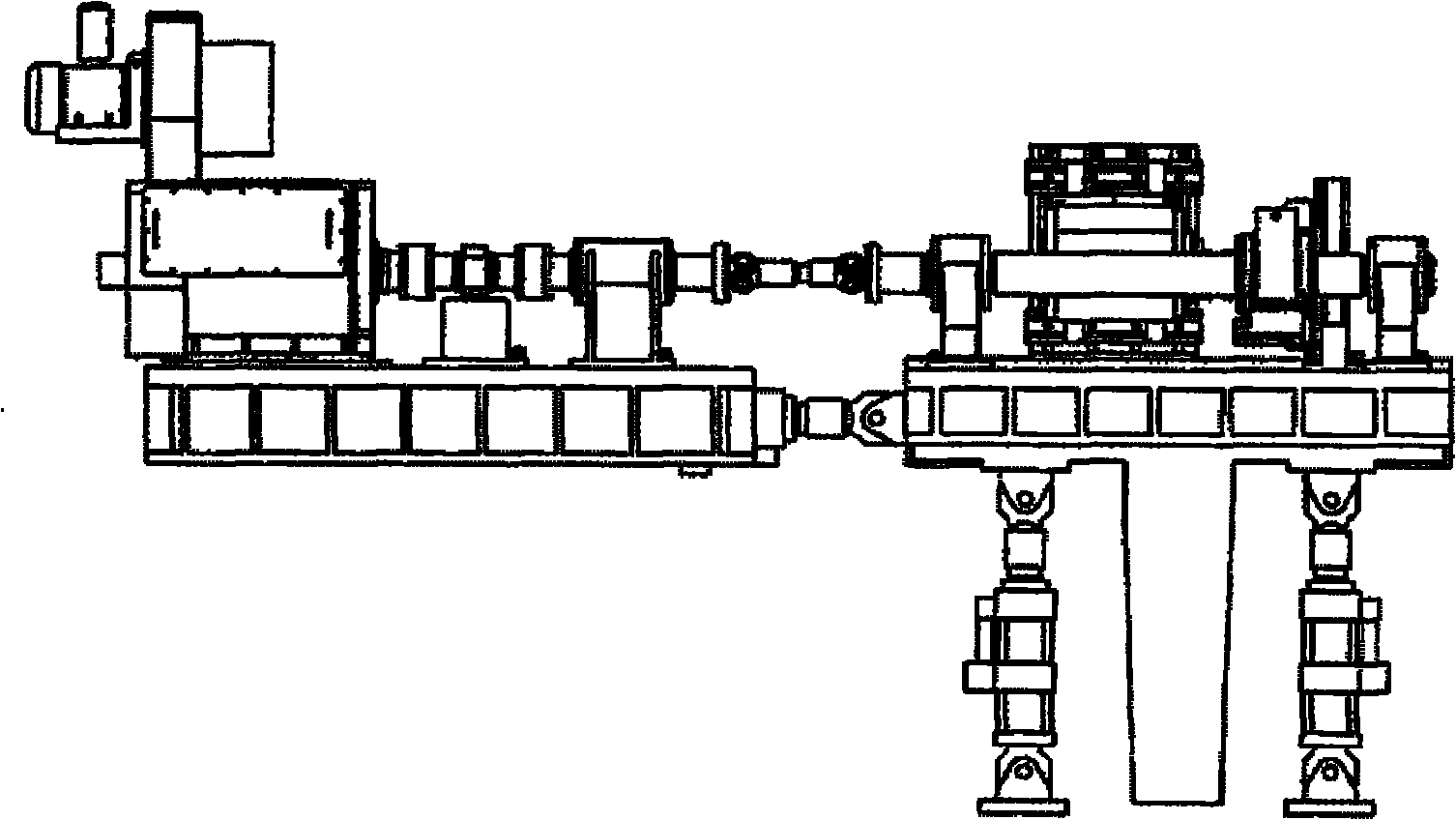

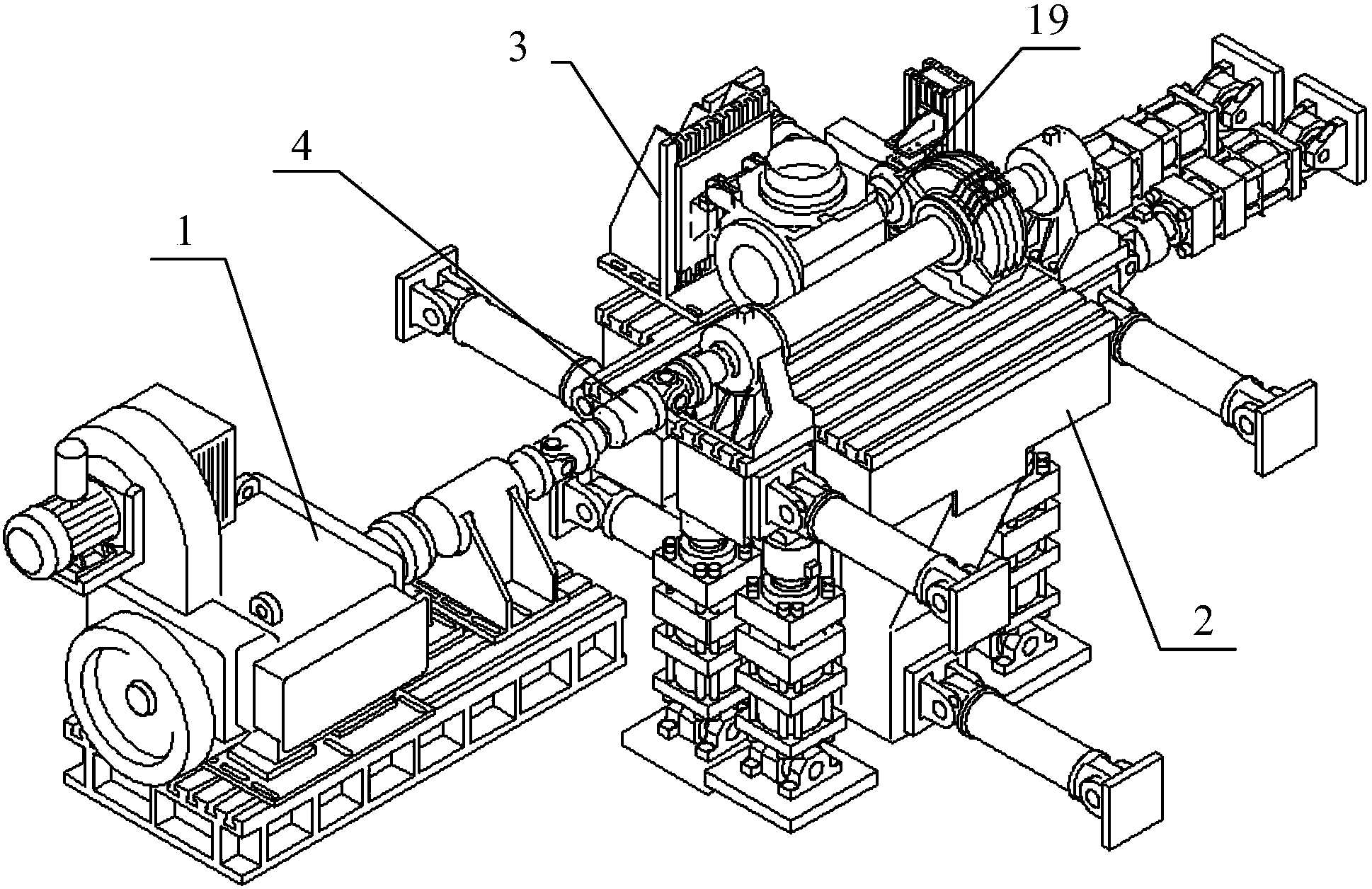

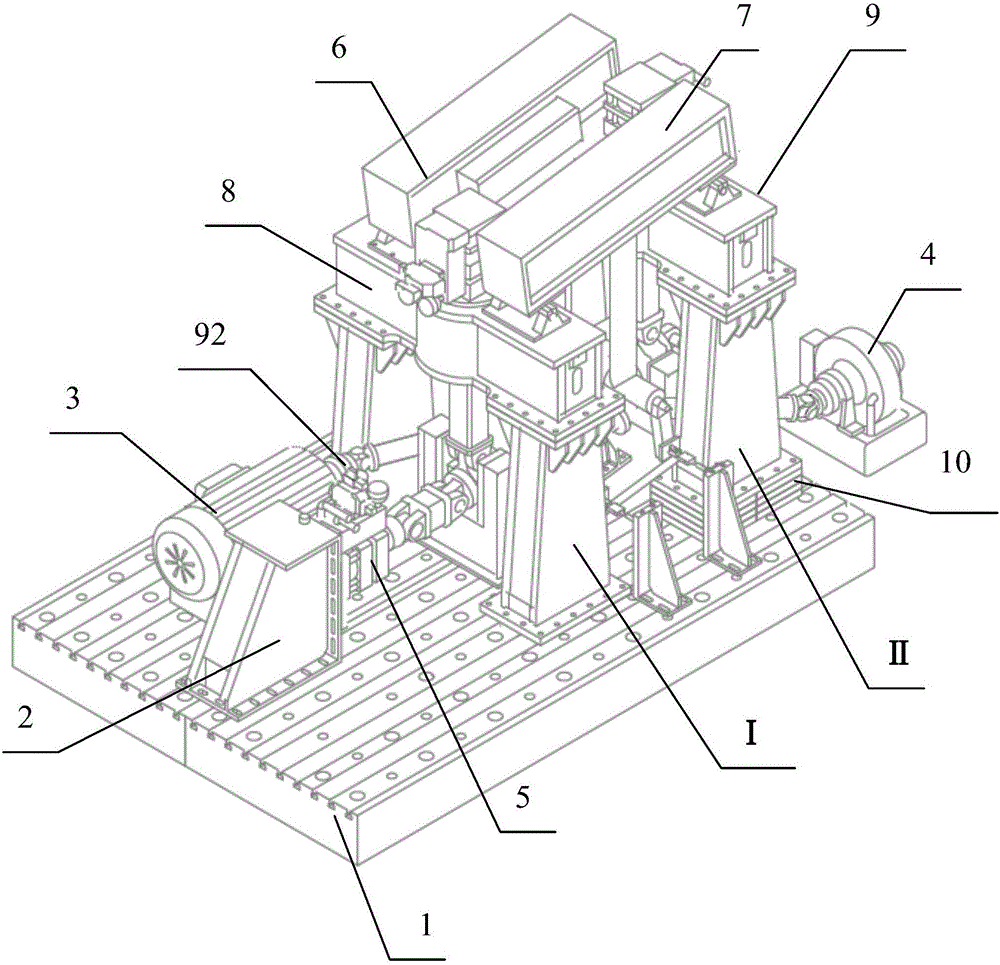

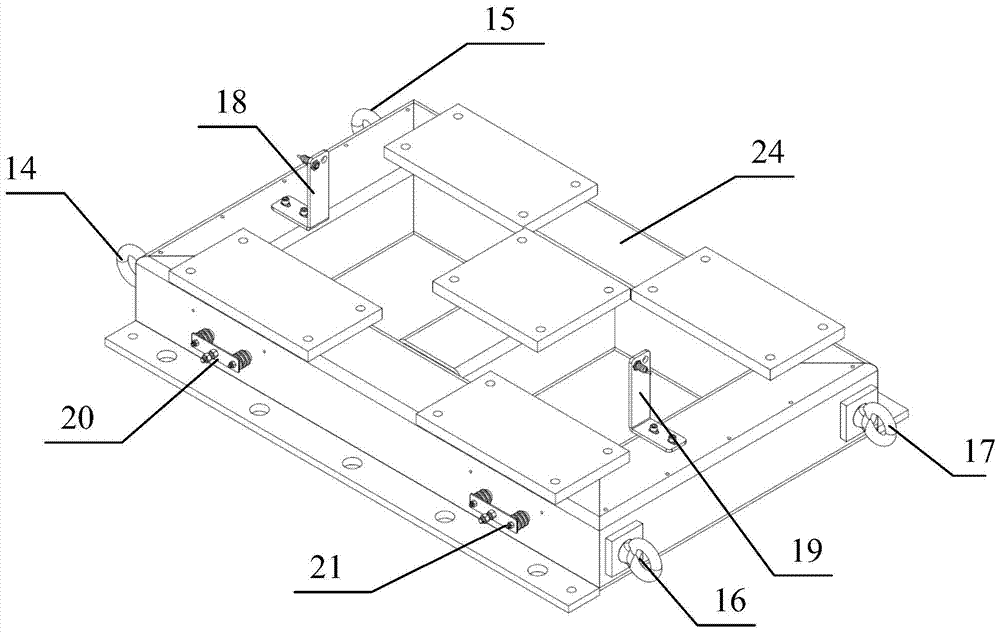

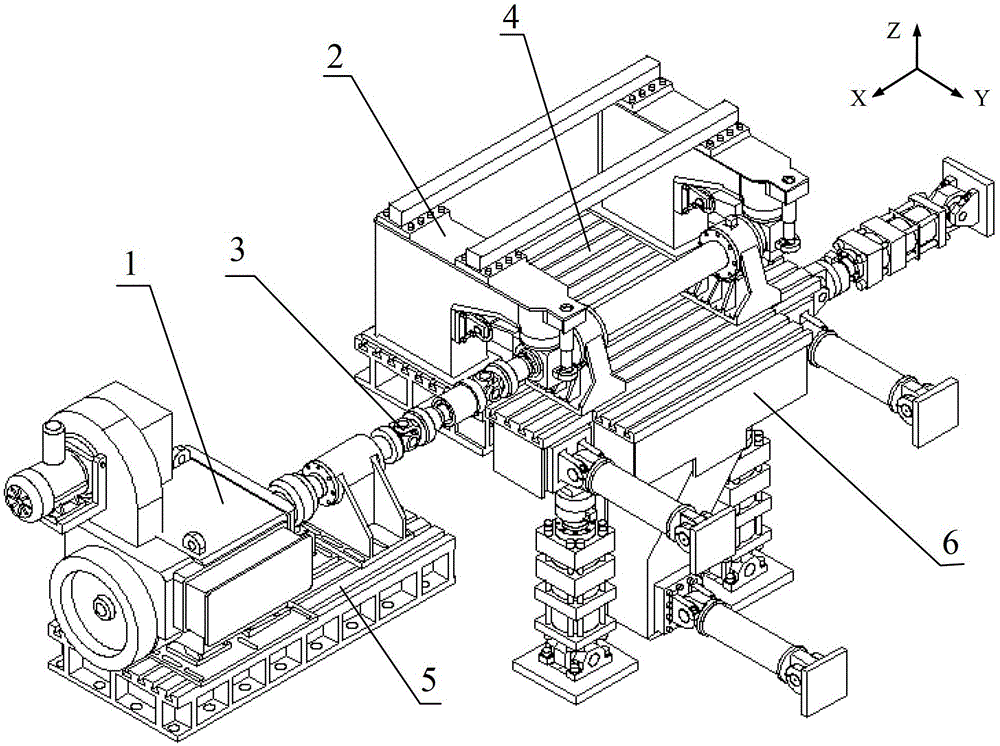

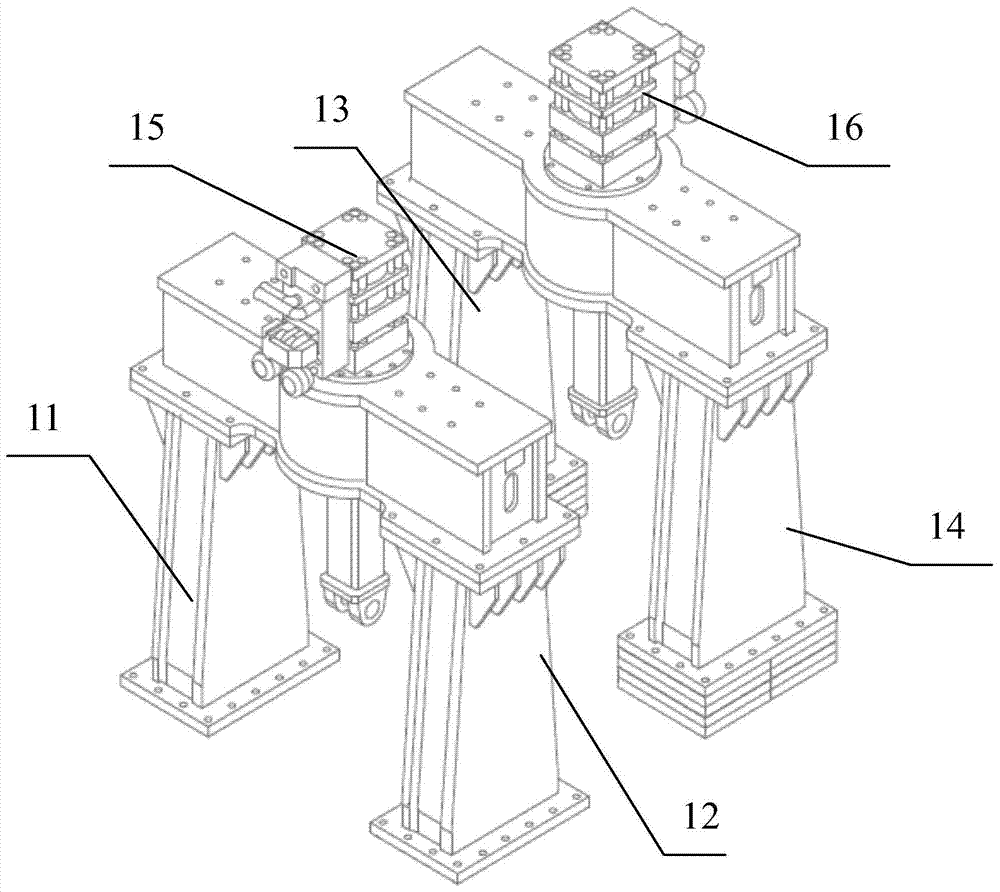

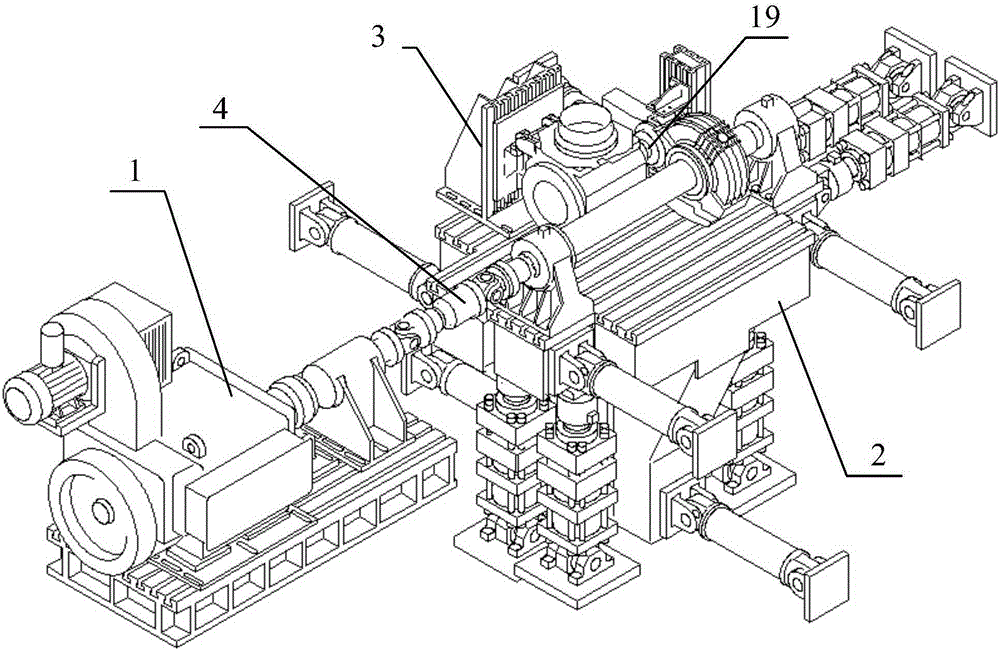

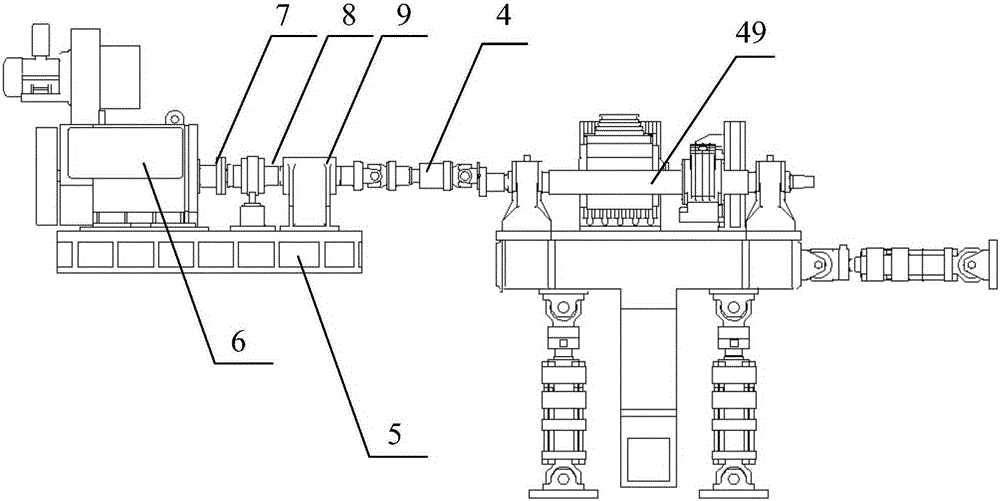

The invention discloses a high-speed train transmission system assembly reliability test bed. The test bed comprises a power transmission flexibility test device, a three-degree-of-freedom vibration simulation test device, and a high-speed train transmission system assembly reliability test device. The three-degree-of-freedom vibration simulation test device and the high-speed train transmission system assembly reliability test device are mounted on the foundation in parallel; a crossbeam of the three-degree-of-freedom vibration simulation test device and a high-speed train transmission system assembly support platform of the high-speed train transmission system assembly reliability test device have a parallel distance of 20 to 40 mm; and the upper work surface of the crossbeam and the upper work surface of the high-speed train transmission system assembly support platform are on the same horizontal plane. The three-degree-of-freedom vibration simulation test device is connected with the power transmission flexibility test device mounted on the foundation through a transverse actuator; and the power transmission flexibility test device is connected with the high-speed train transmission system assembly reliability test device through a cross-shaft type universal coupling.

Owner:JILIN UNIV

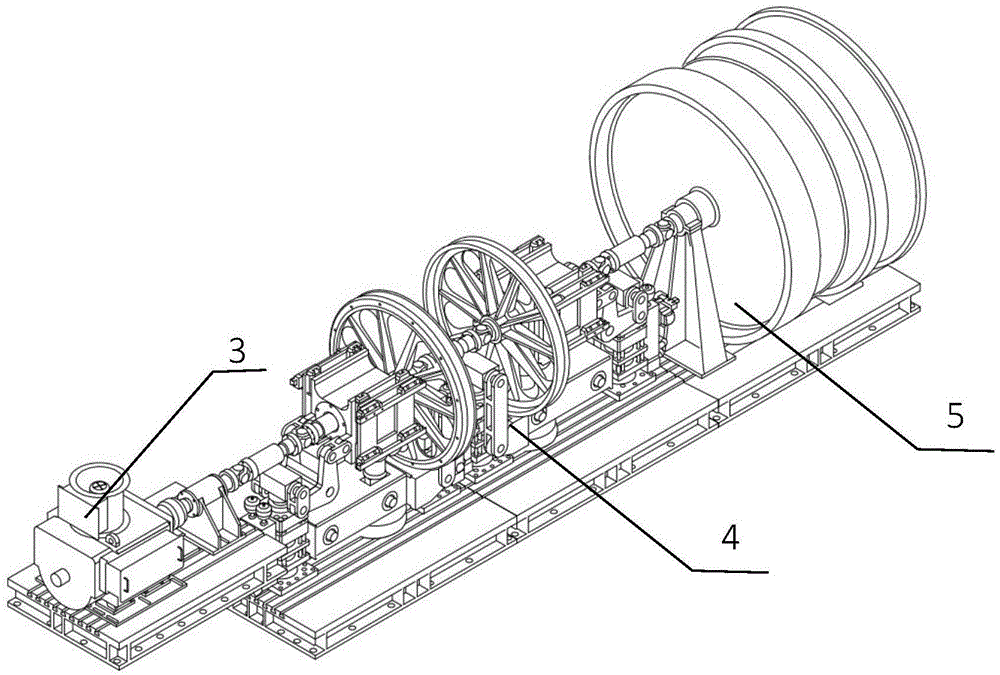

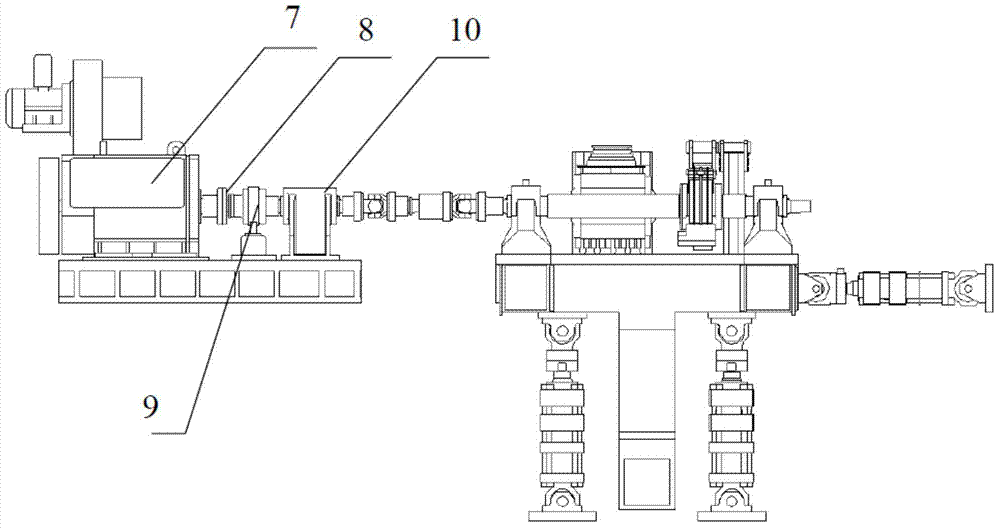

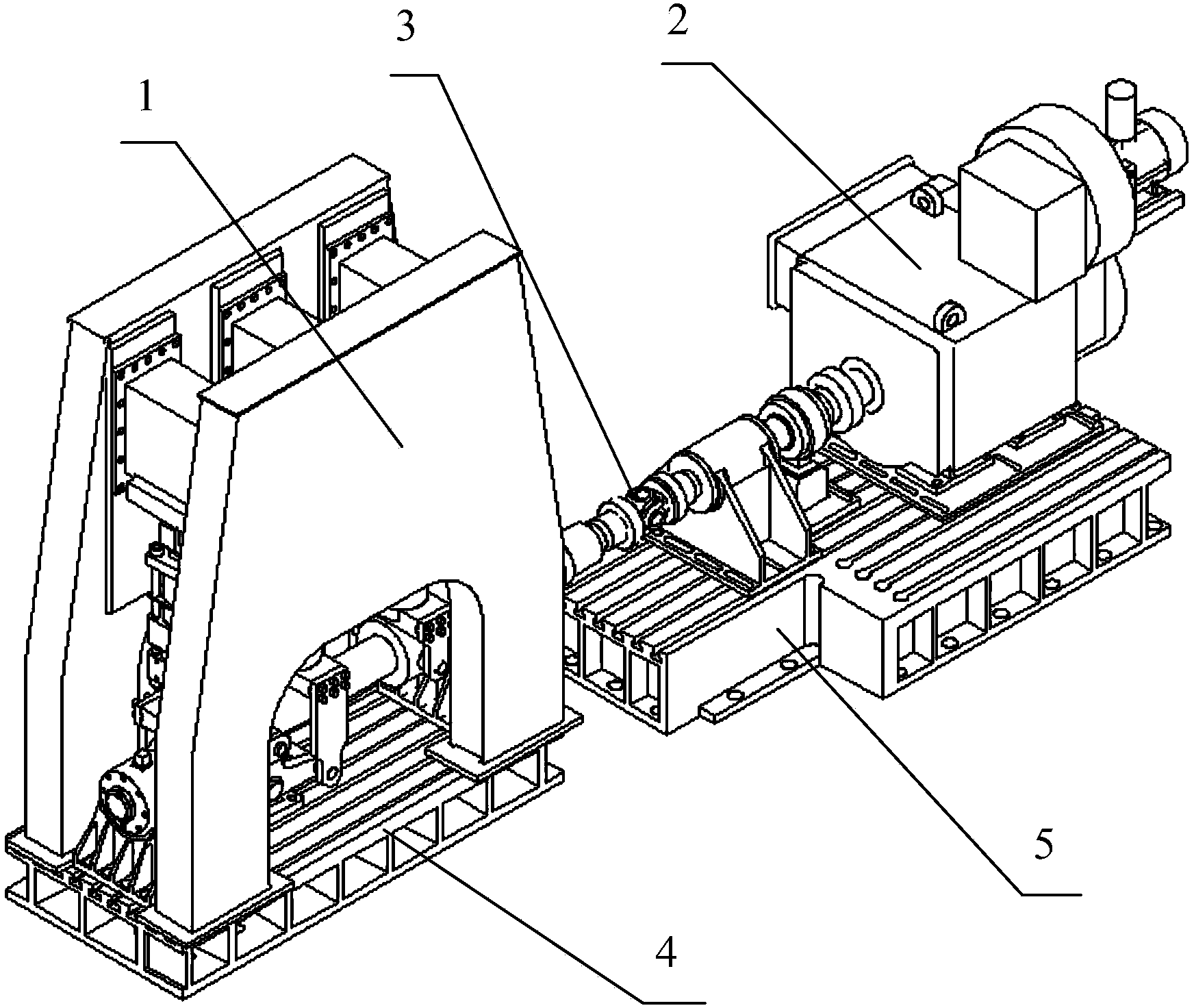

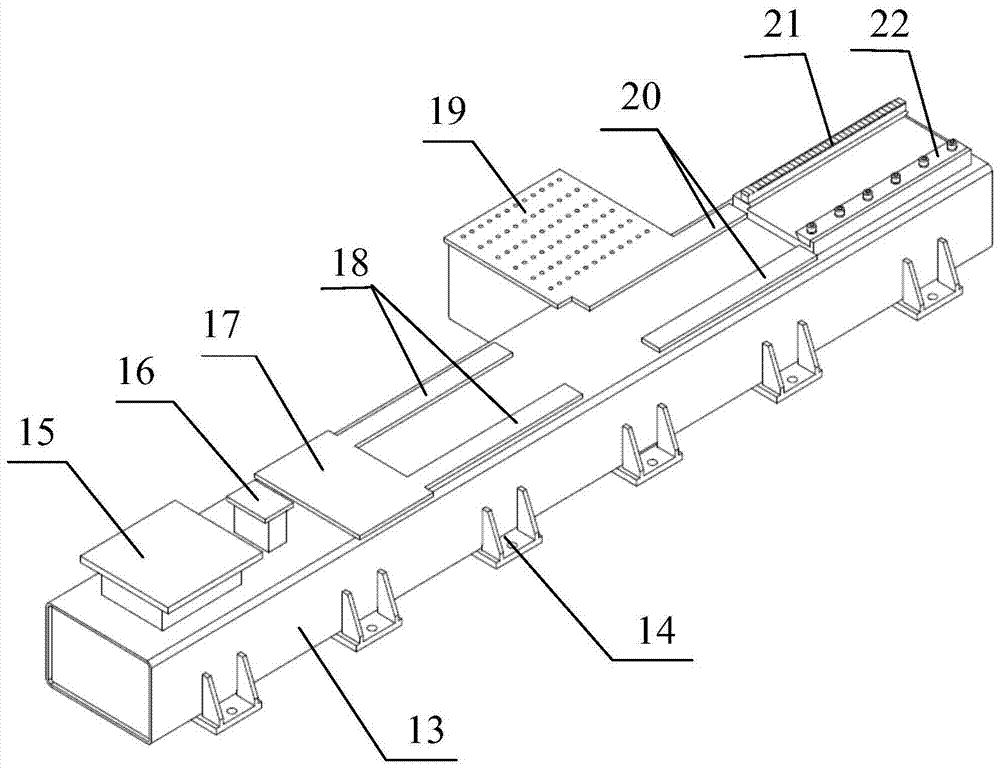

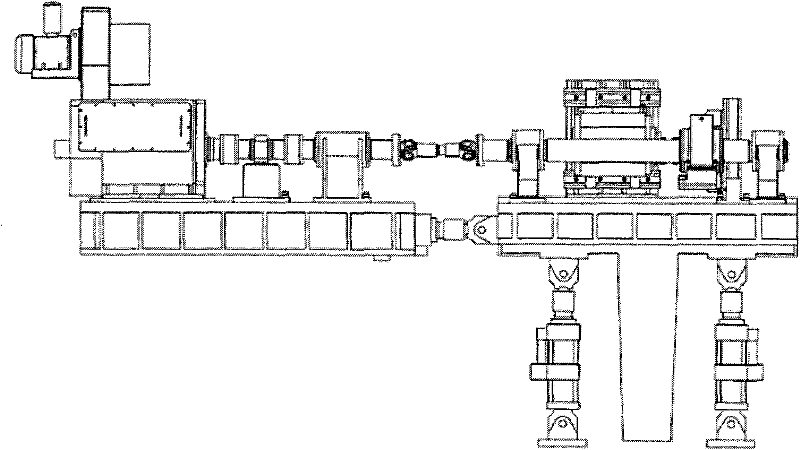

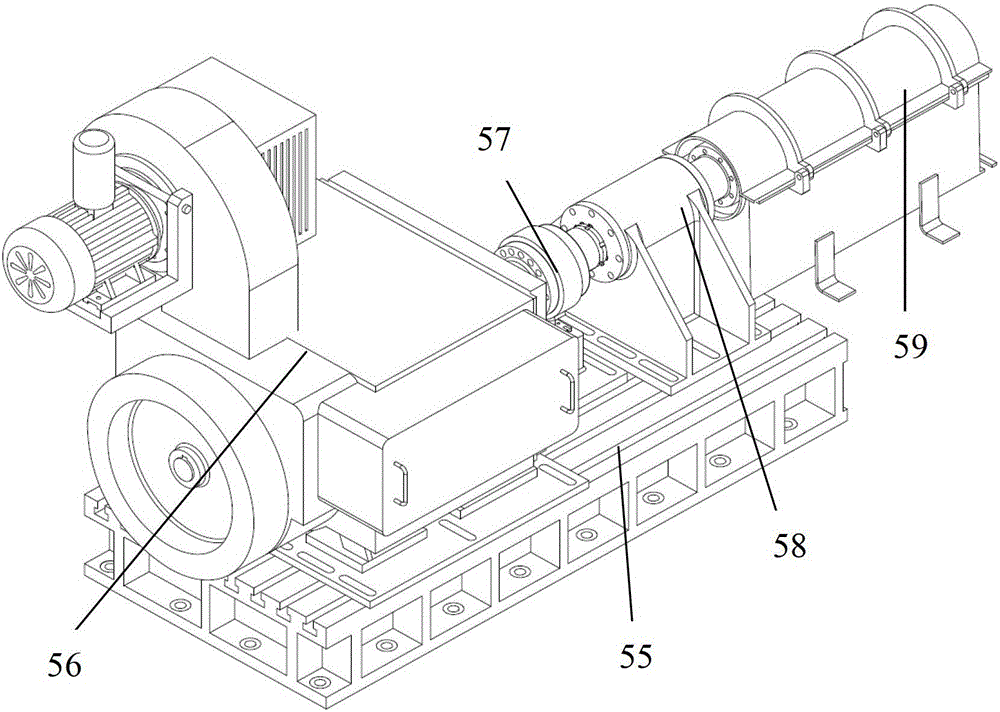

High-speed train gearbox no-load running-in test bench

InactiveCN105466683ASafe and secure clampingEfficient deliveryMachine gearing/transmission testingRailway vehicle testingMobile endSound level meter

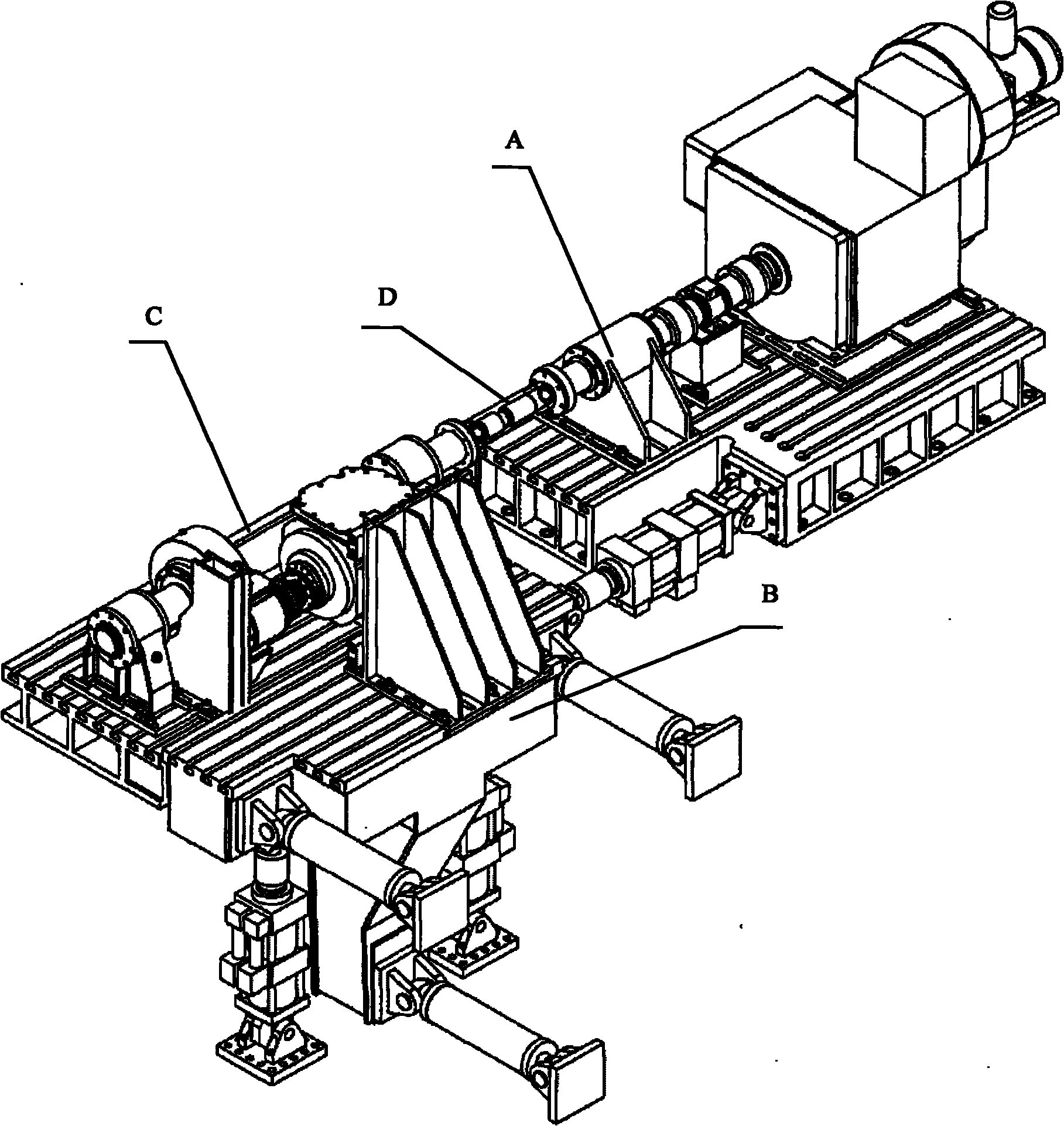

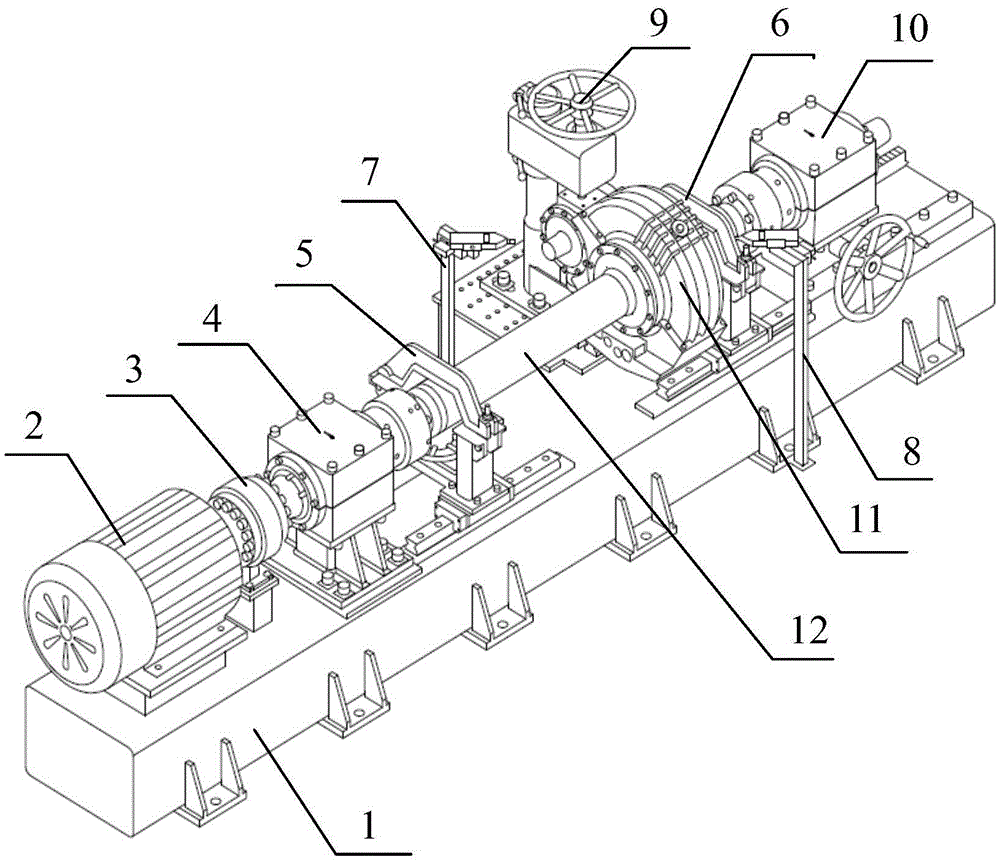

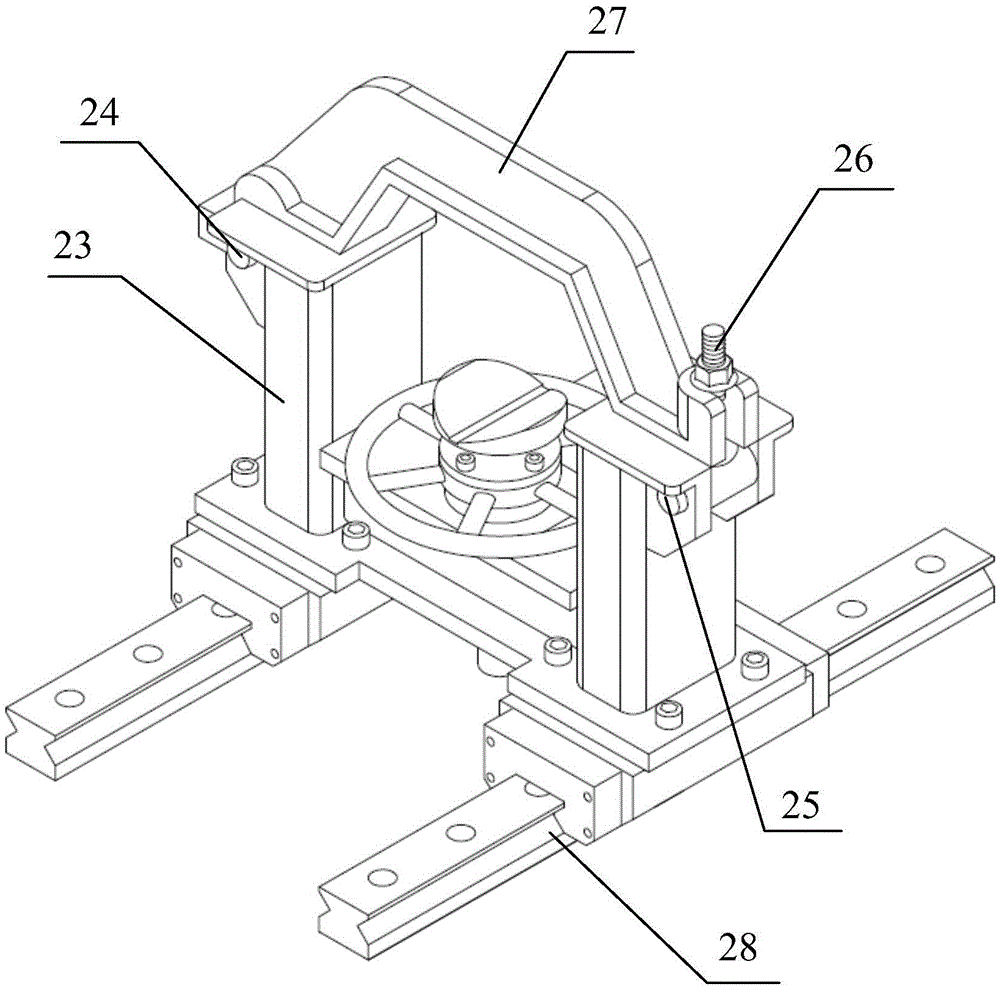

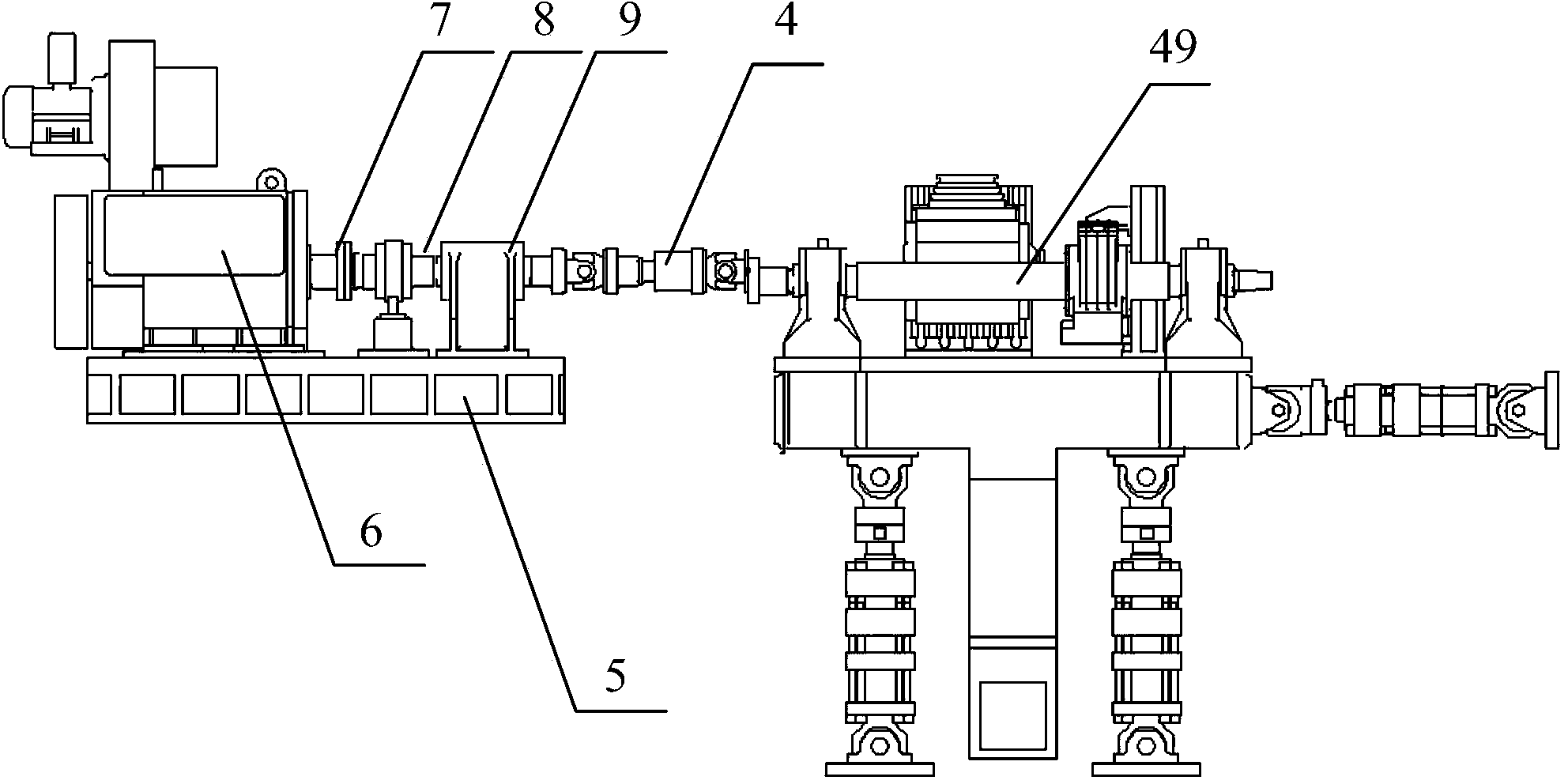

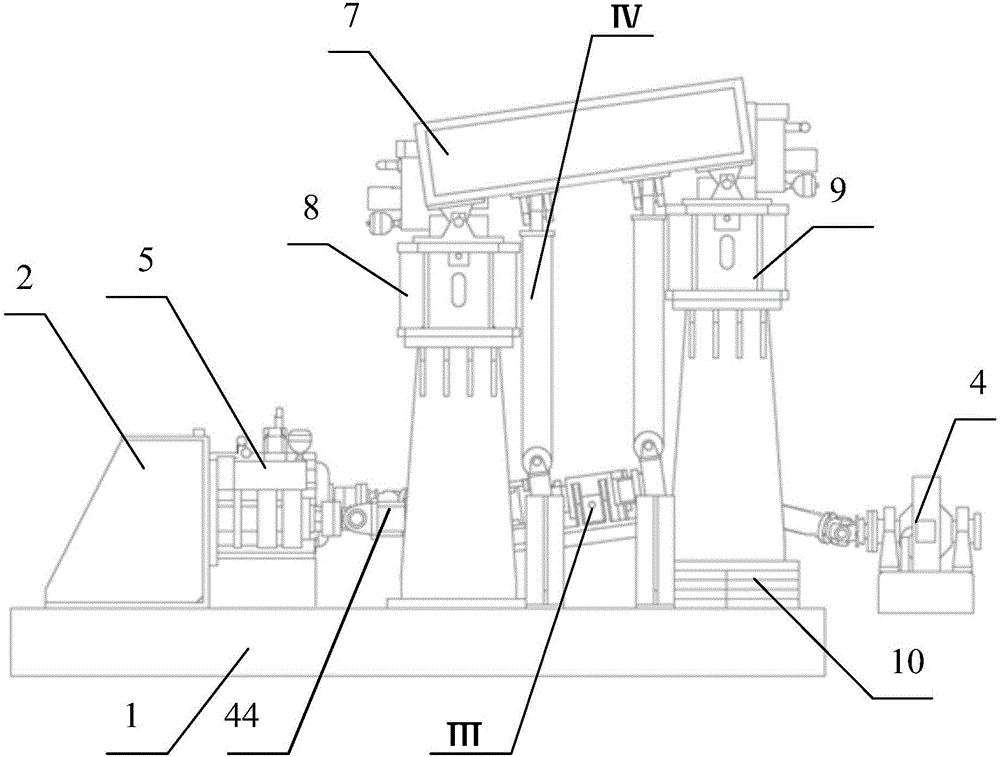

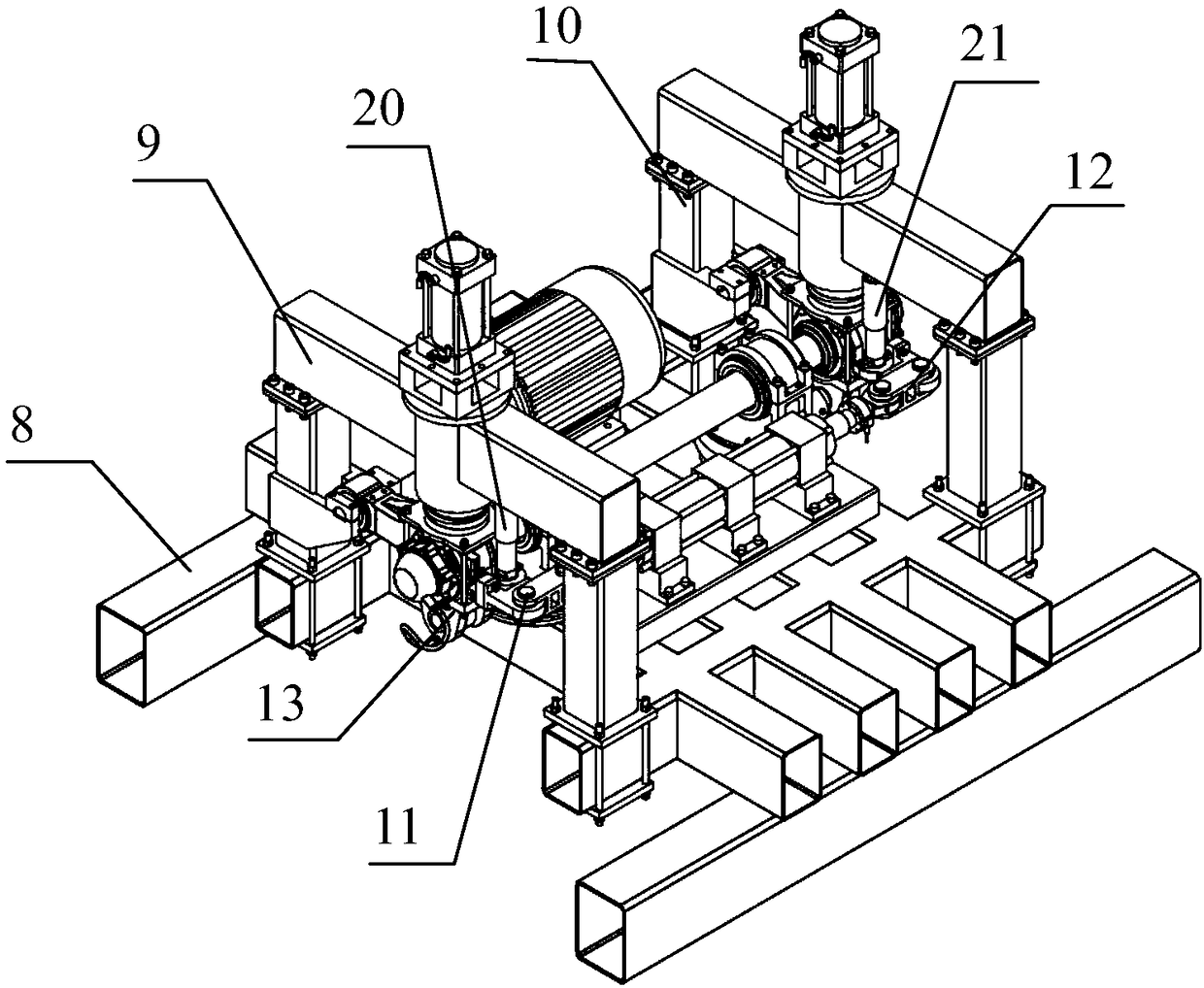

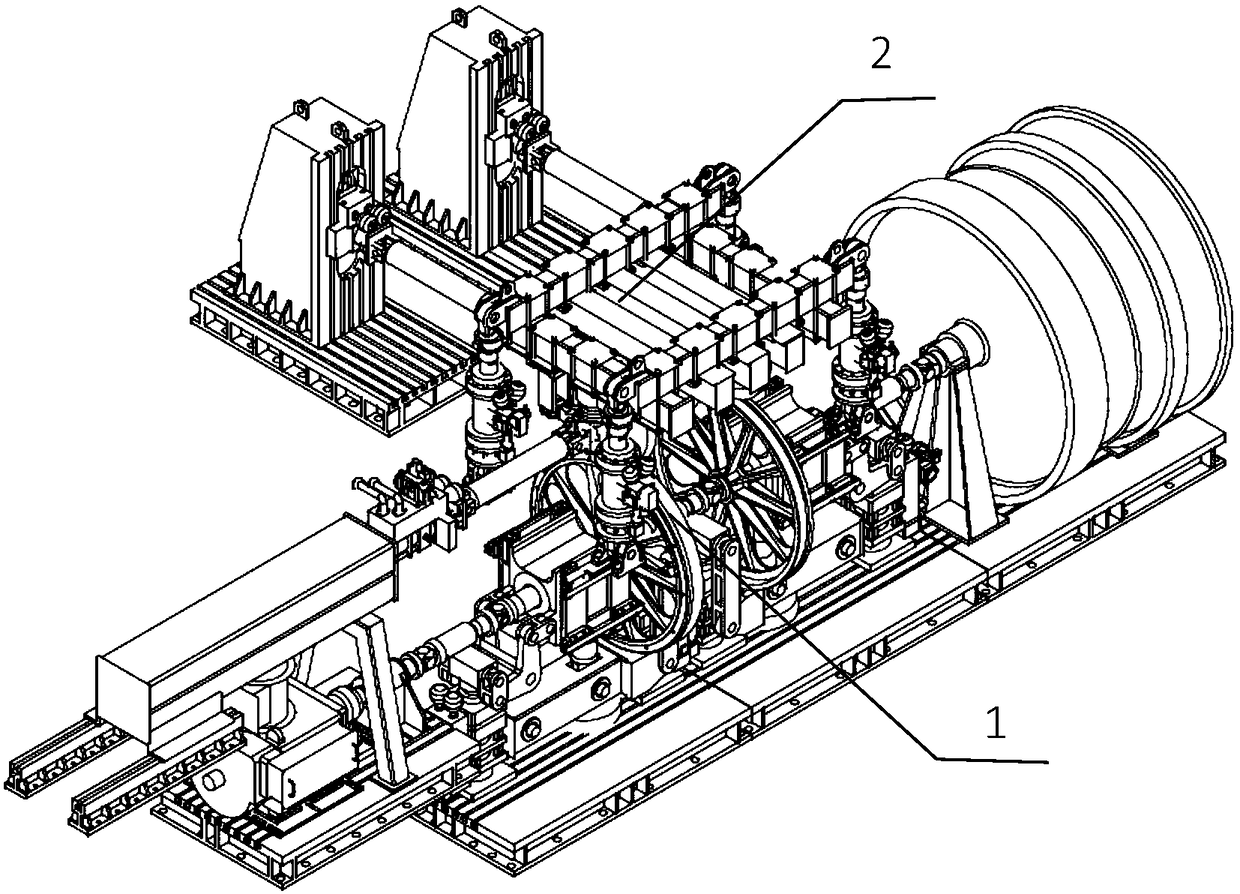

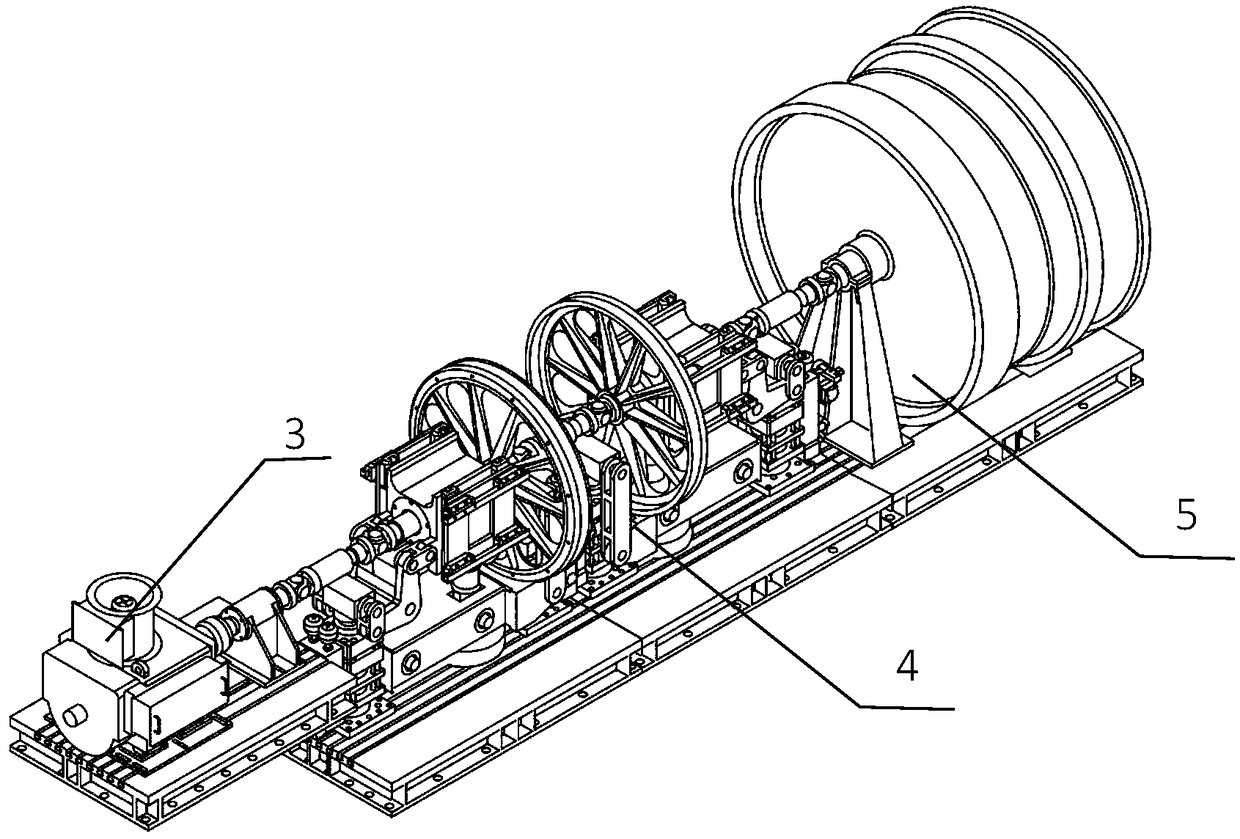

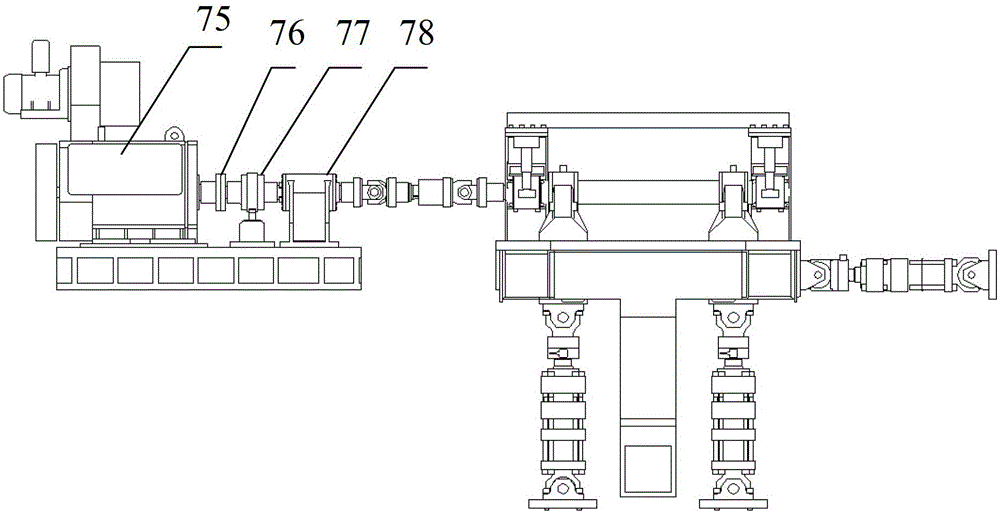

The invention relates to a high-speed train gearbox no-load running-in test bench, which is composed of a driving device, axle end transition bearing positioning clamping devices, a large-span mobile wheel set axle positioning supporting device, a gearbox input end pressing vertical column device and a noise testing device, wherein the driving device is arranged at the left end of a test bench base (1); a fixing-end and a mobile-end transition bearing positioning clamping devices are arranged at the left side and the right side of the test bench base (1) respectively; the large-span mobile wheel set axle positioning supporting device is composed of two sets of large-span mobile wheel set axle positioning supporting devices with the same structure; the gearbox input end pressing vertical column device is arranged on the test bench base (1); and the noise testing device comprises noise testing sound level meters and supporting tube assemblies arranged at the input end and the output end of the gearbox respectively. A series of technical problems that the existing gearbox no-load running-in test bench is complicated to assemble and disassemble, an axle journal is damaged, a high rotation speed can not be met and the like can be solved.

Owner:JILIN UNIV

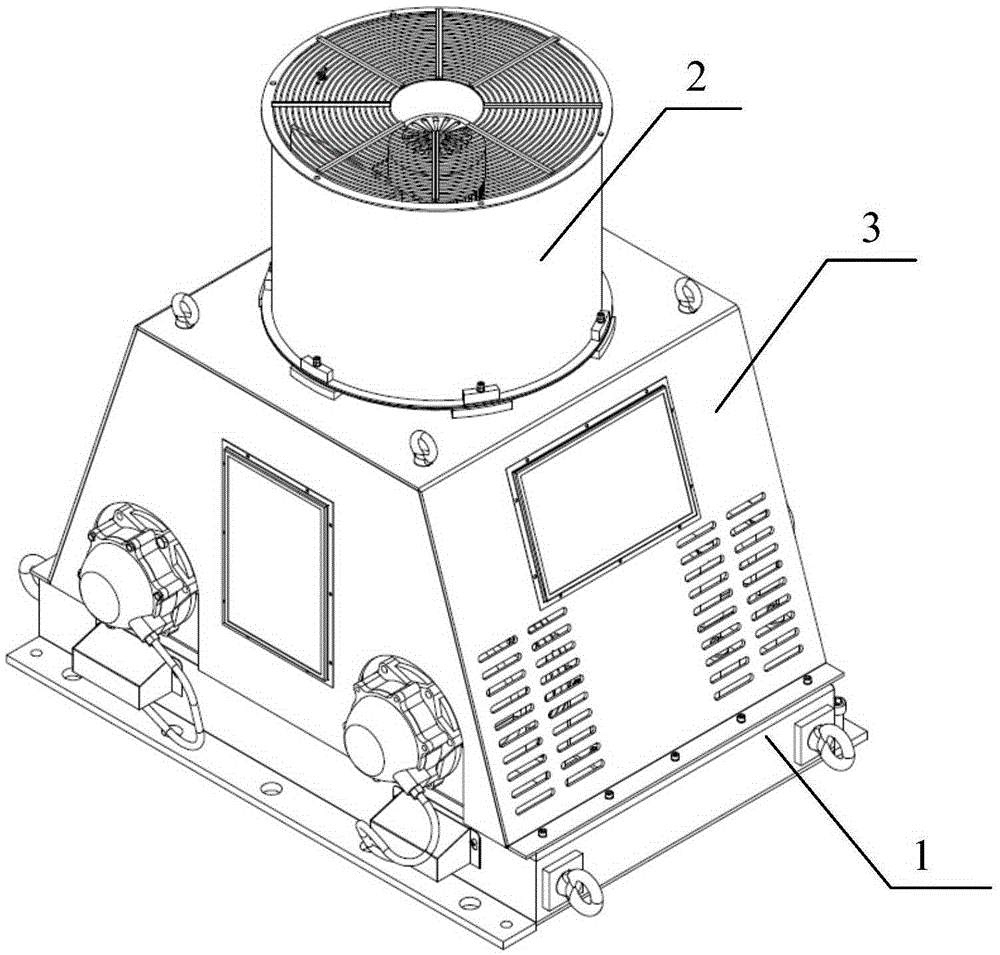

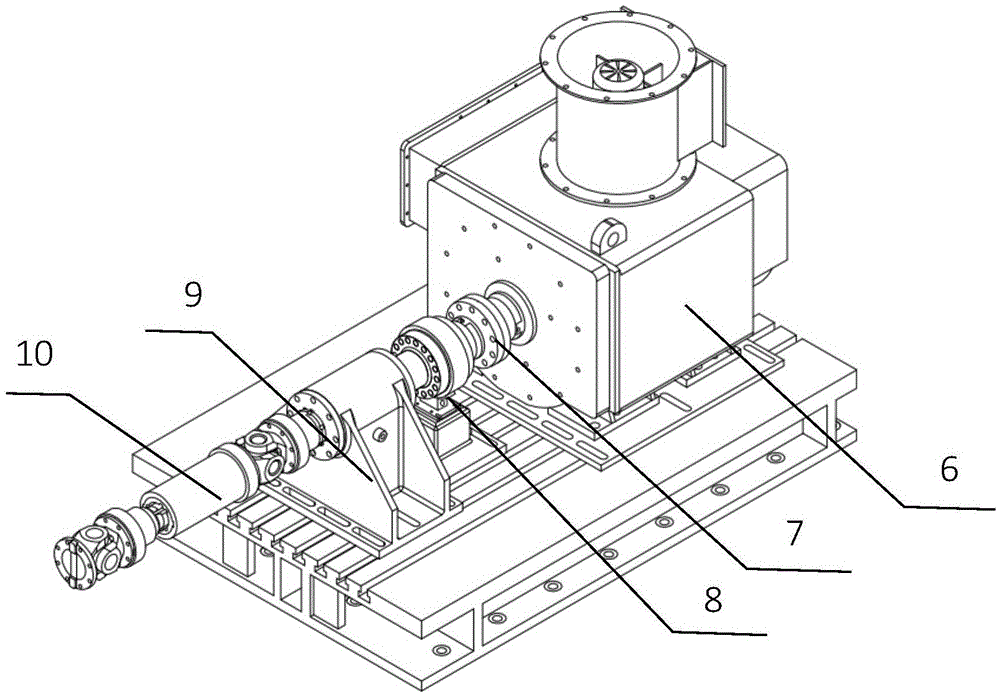

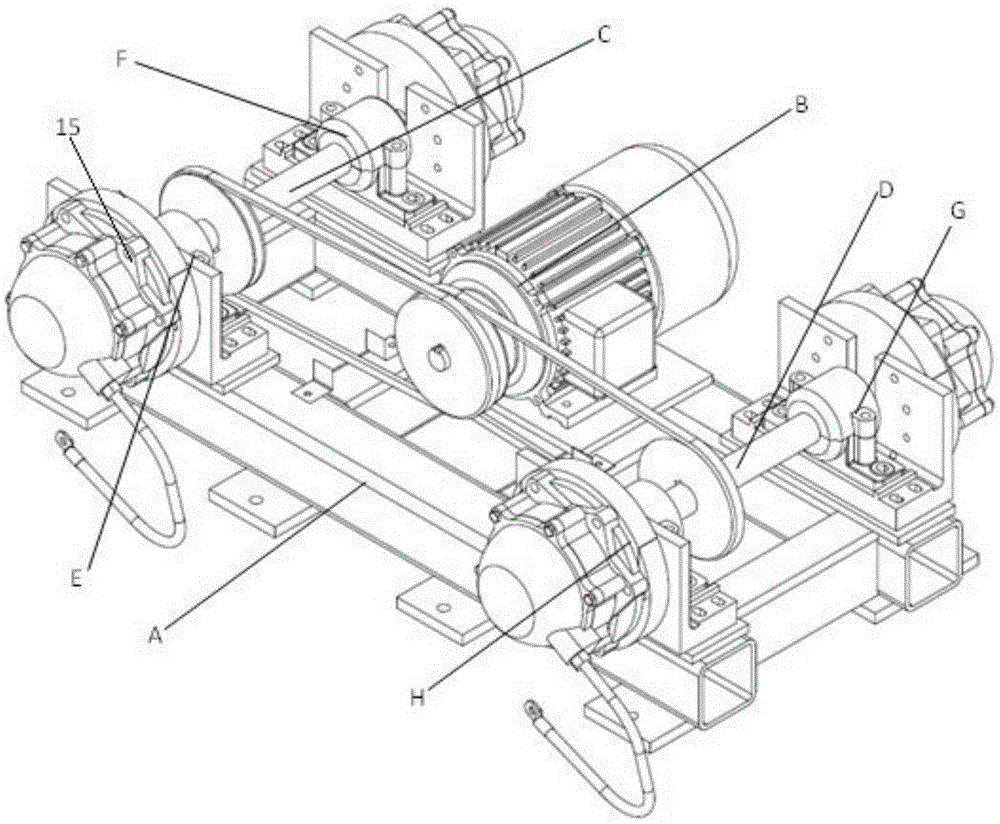

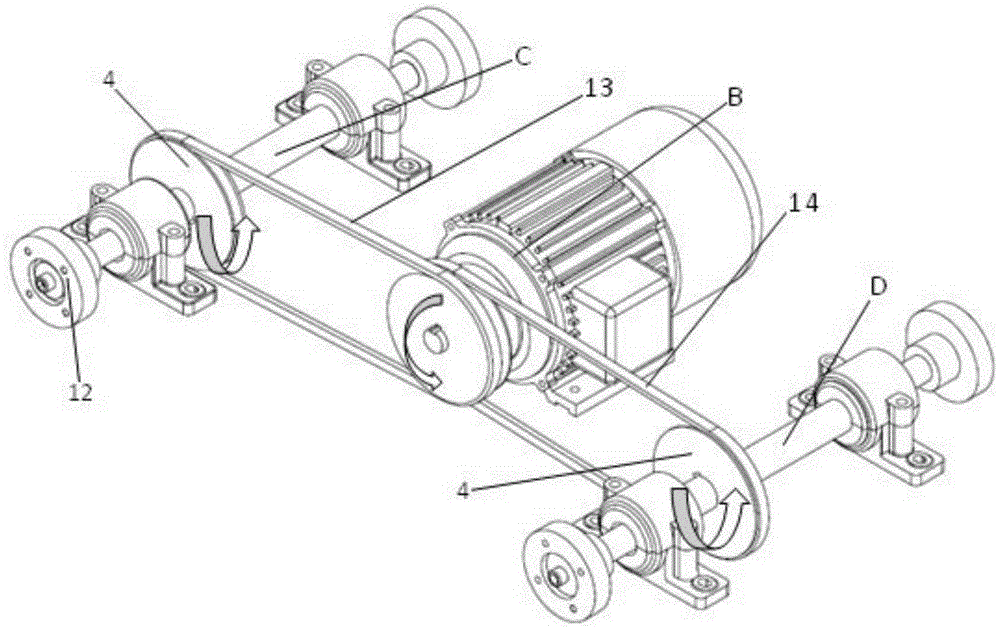

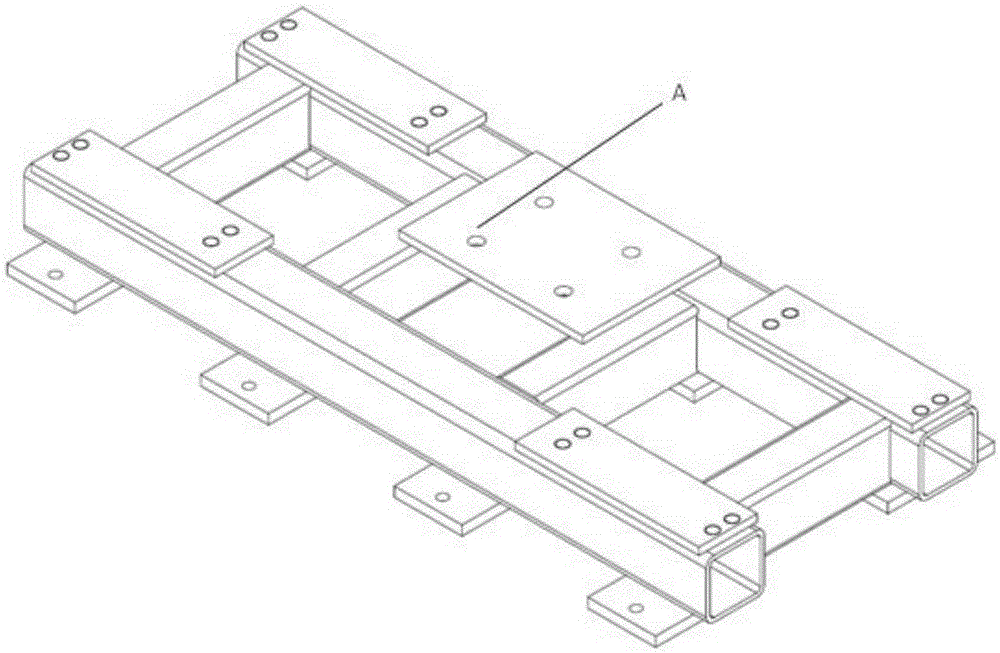

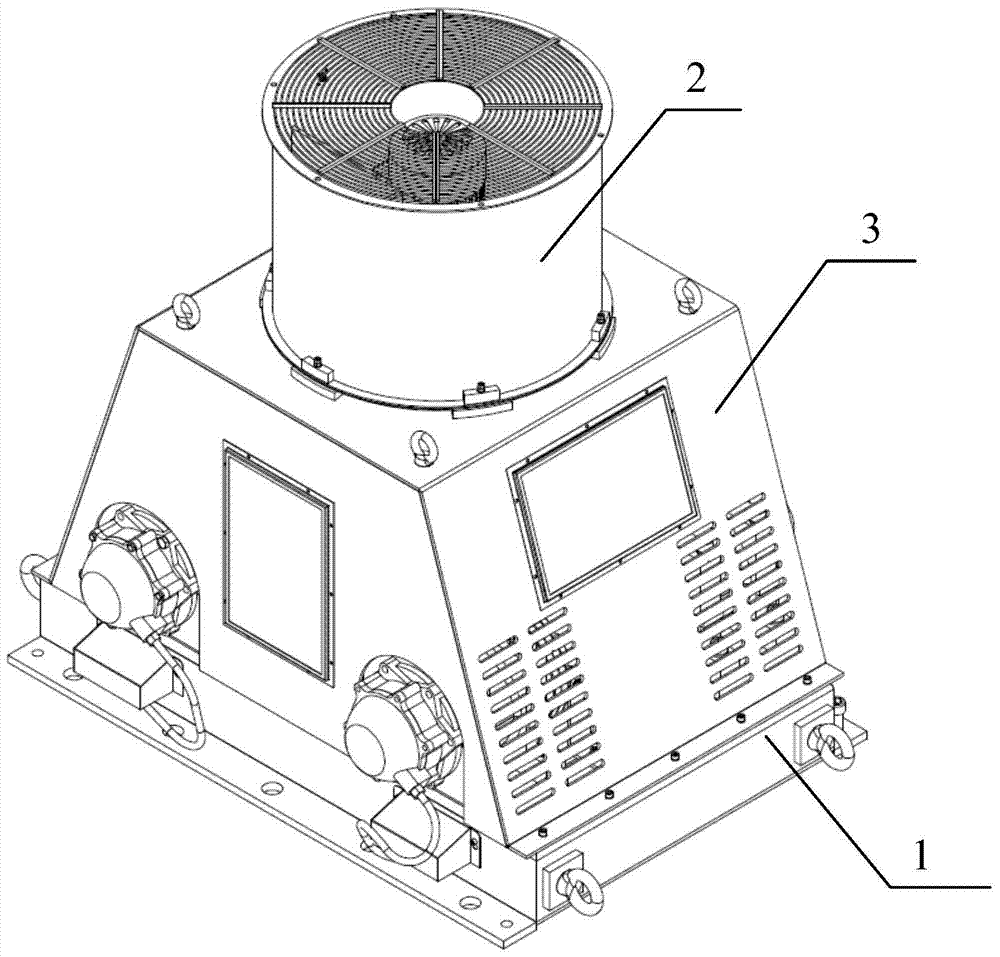

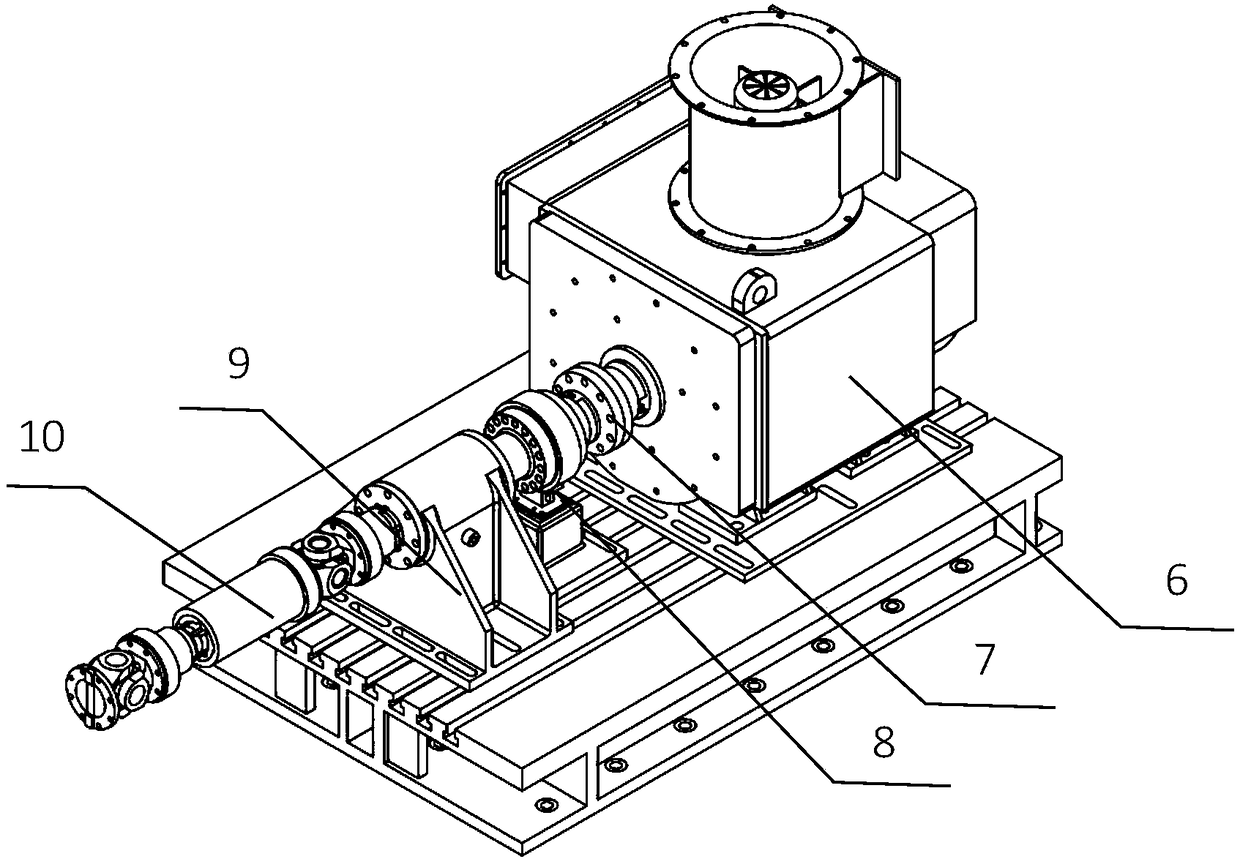

Rail vehicle shaft end grounding apparatus wear test bench

The invention relates to a rail vehicle grounding drainage test apparatus, and more specifically relates to a rail vehicle shaft end grounding apparatus wear test bench. The test bench comprises a test equipment assembling body, a heat dissipation fan assembling body and a test apparatus protective cover assembling body, wherein the test apparatus protective cover assembling body is fixed above the test equipment assembling body; the heat dissipation fan assembling body is fixed above the test apparatus protective cover assembling body, the test equipment assembling body comprises two symmetrically arranged test shaft assembly and bearing pedestal assembling bodies and a motor and motor support column assembling body; and the motor and motor support column assembling body and the two test shaft assembly and bearing pedestal assembling bodies are respectively in transmission connection through driving belt assemblies. Through a double-test-shaft transmission test apparatus provided by the invention, the rotating speed and the current working condition of a motor train unit in an actual track can be accurately simulated, a quite good test foundation is provided for a loss test of a rail vehicle shaft end grounding apparatus, and the accuracy of test data is guaranteed.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

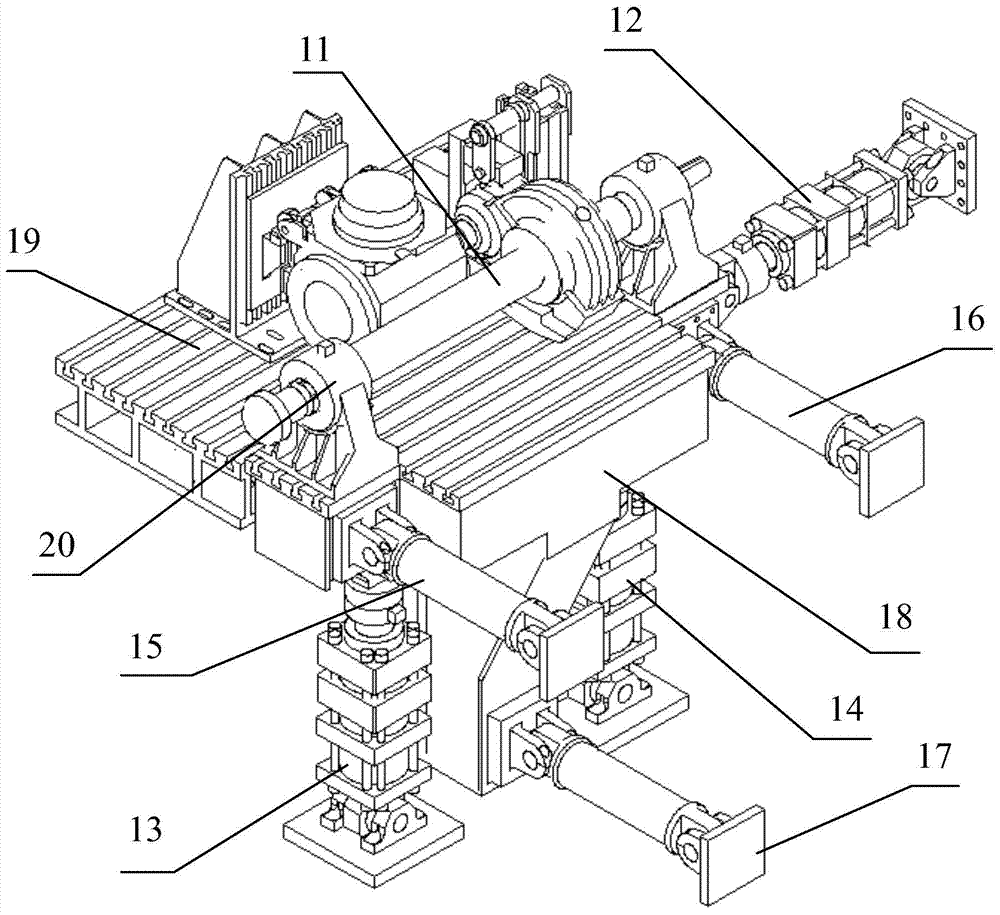

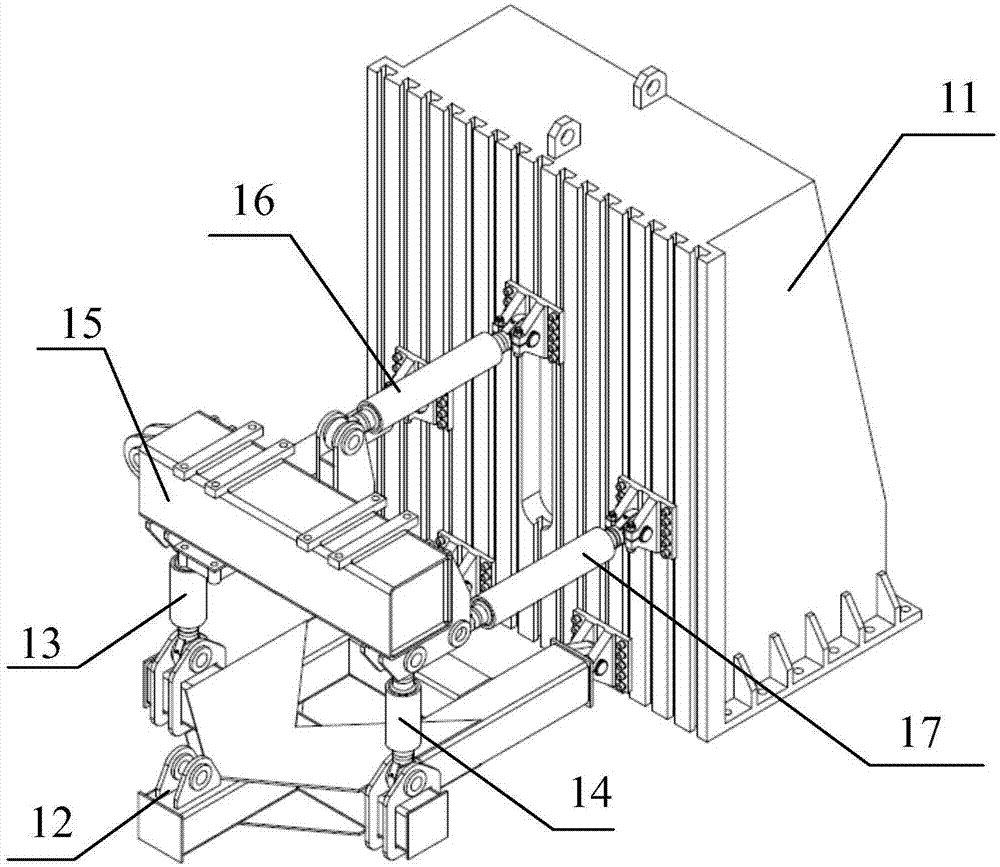

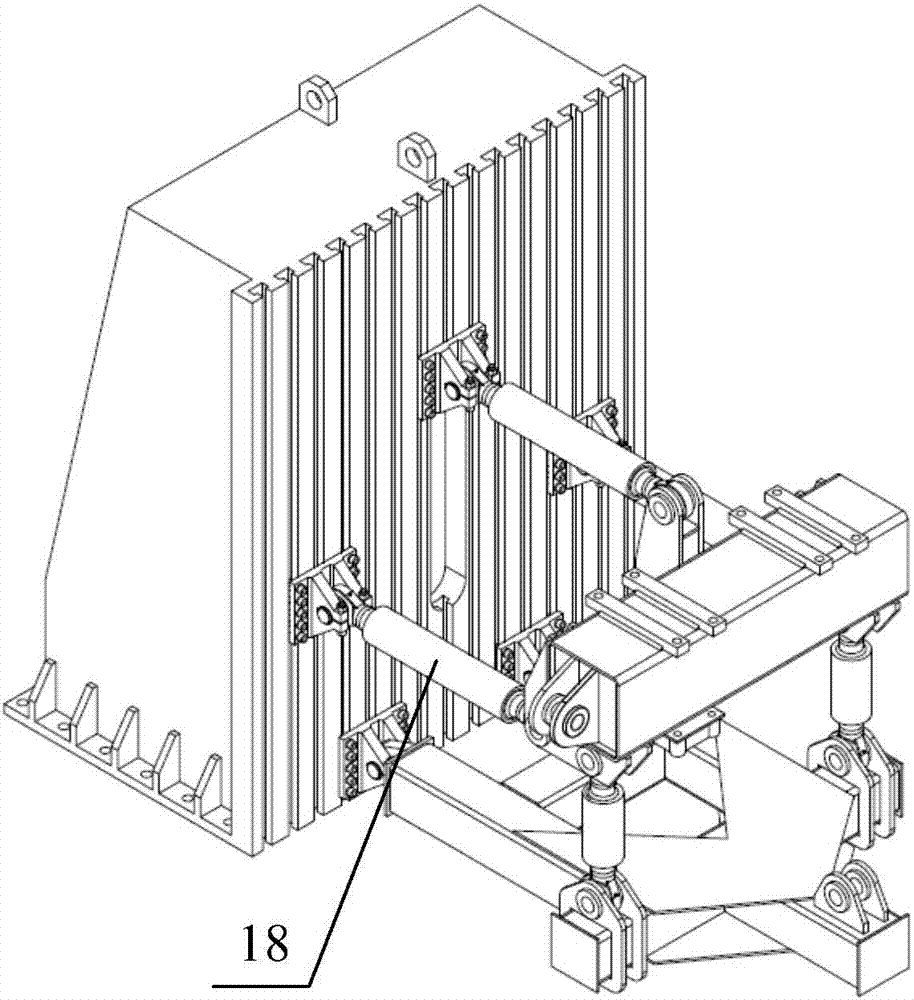

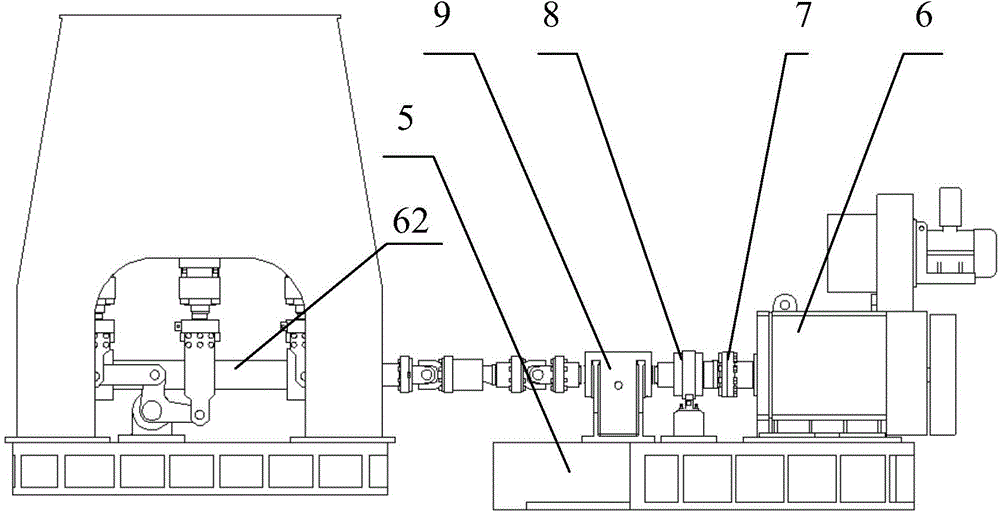

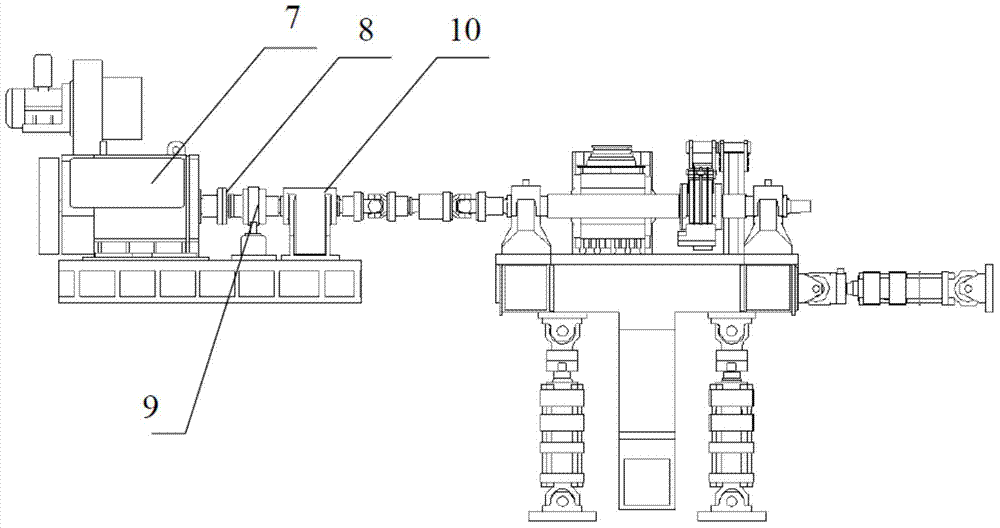

Reliability test bench of two-body six-dimensional vibration drive train assembly for high-speed motor train unit

InactiveCN103630358ATruly reflect the status of fatigue damageGood test foundationMachine gearing/transmission testingRailway vehicle testingShaped beamReduction drive

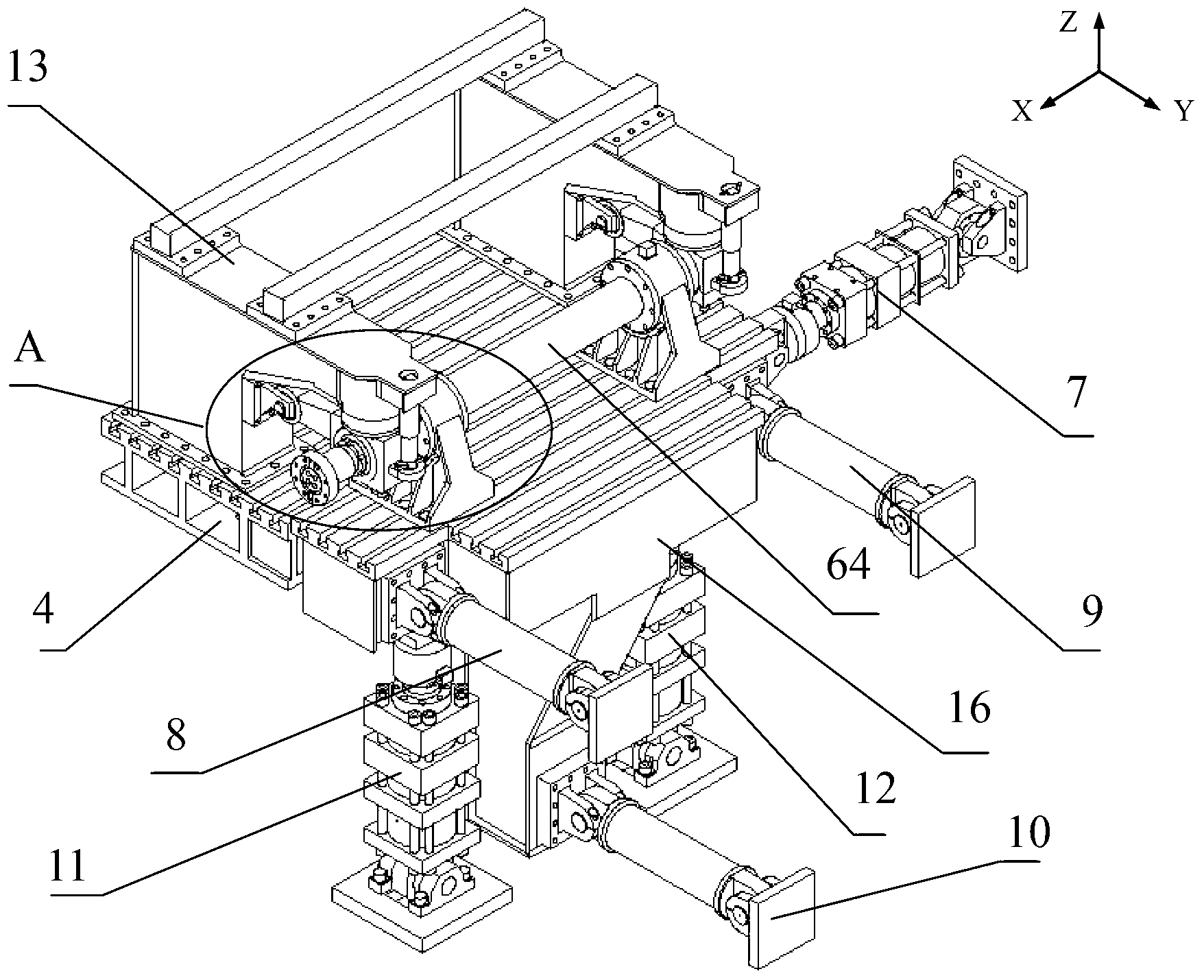

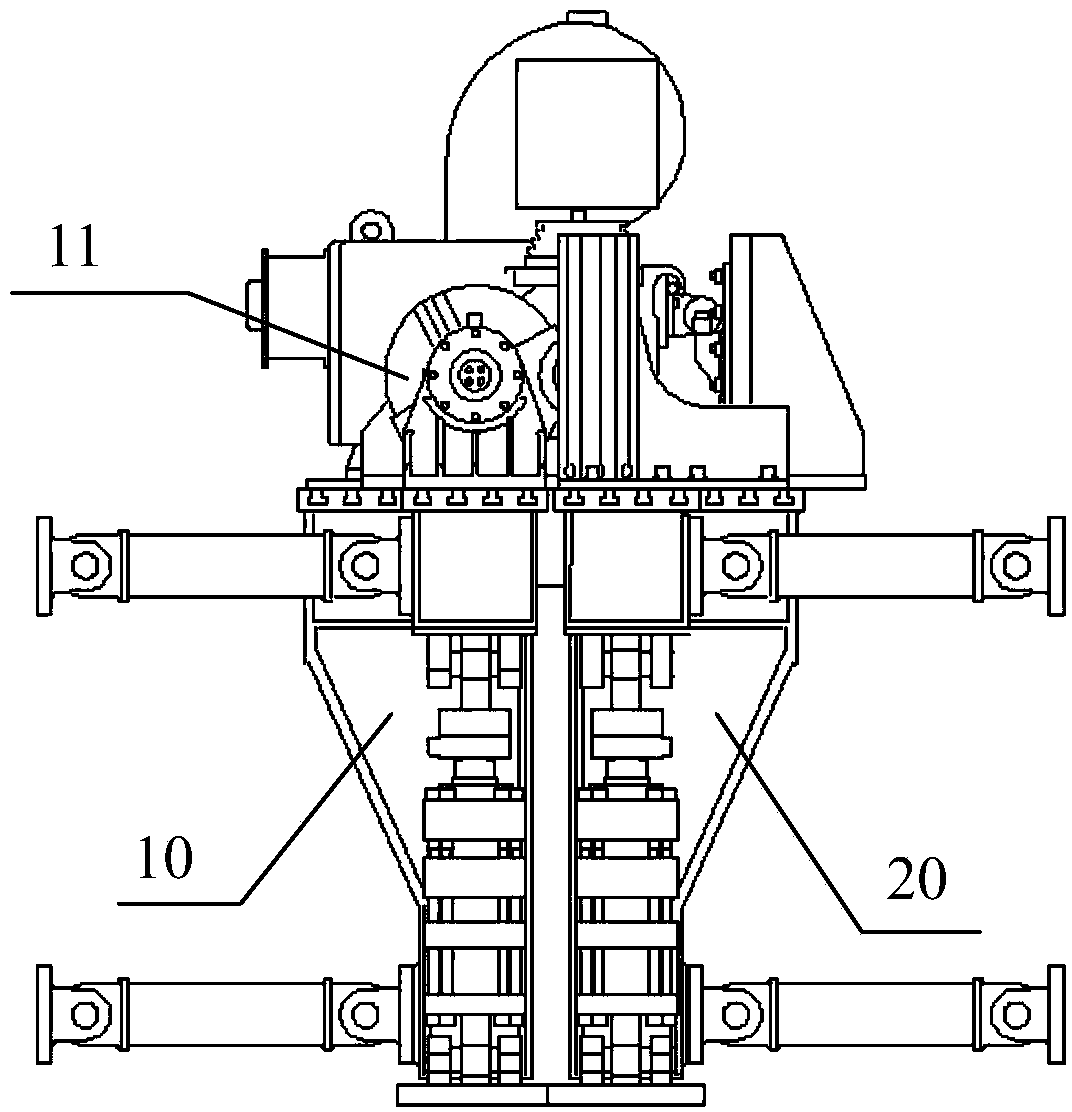

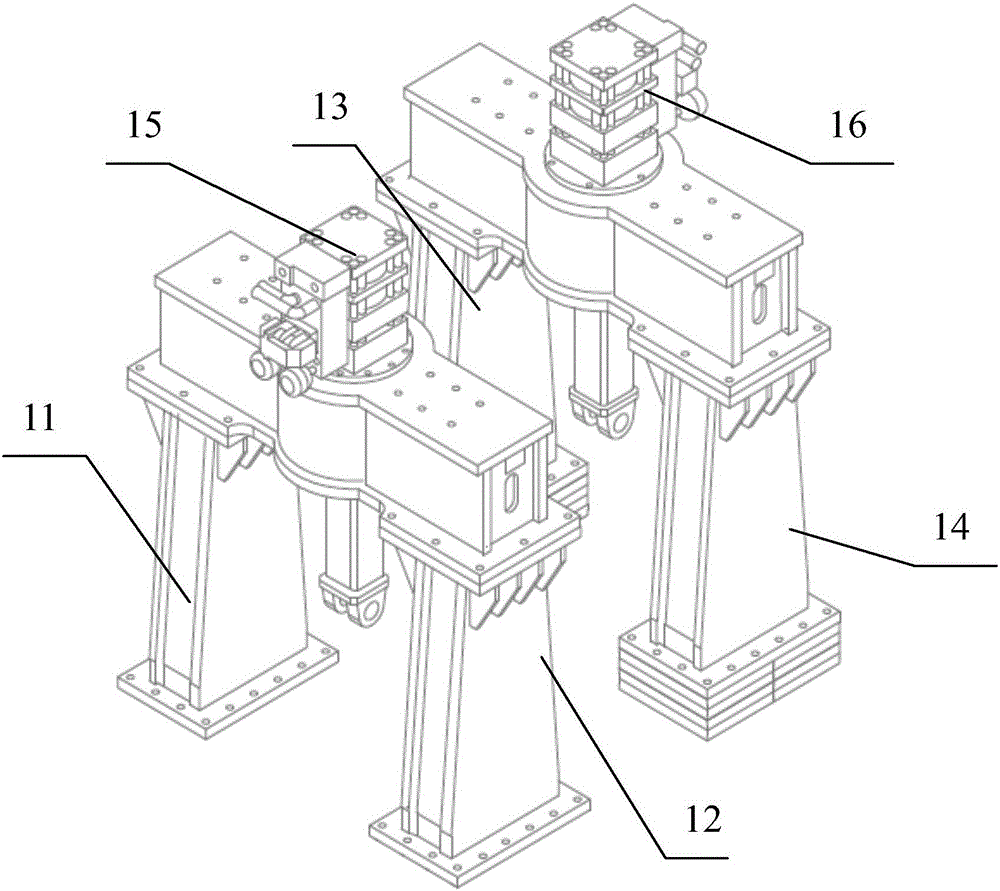

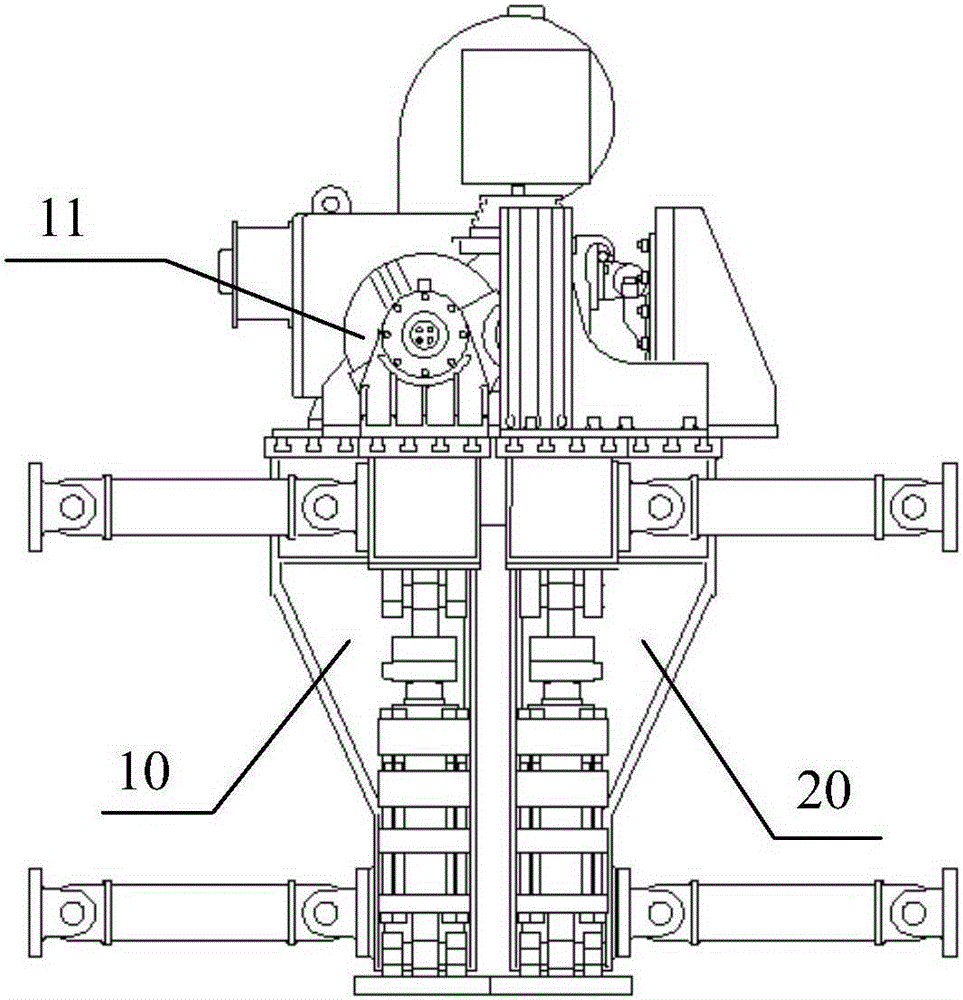

The invention discloses a reliability test bench of a two-body six-dimensional vibration drive train assembly for a high-speed motor train unit, and solves the problem that a drive train is put into a static environment to respectively research a reducer or a drive motor in the prior art. The reliability test bench comprises a three-degree-of-freedom vibration table of a vibration shaft assembly and a three-degree-of-freedom vibration table of a traction motor assembly, wherein the three-degree-of-freedom vibration table of the vibration shaft assembly and the three-degree-of-freedom vibration table of the traction motor assembly are arranged on a foundation back to back in parallel; the three-degree-of-freedom vibration table of the traction motor assembly comprises a second three-degree-of-freedom vibrating simulation test device, a traction motor, a fixing clamp assembly body and a drive train gear box fixed bracket assembly body; the second three-degree-of-freedom vibrating simulation test device comprises a second vibrating T-shaped beam, a second transverse actuator, a third vertical actuator and a fourth vertical actuator; the traction motor, the fixing clamp assembly body and the drive train gear box fixed bracket assembly body are fixedly connected to the upper surface of the second vibrating T-shaped beam.

Owner:JILIN UNIV

High-speed wheel-rail relation reliability test bed

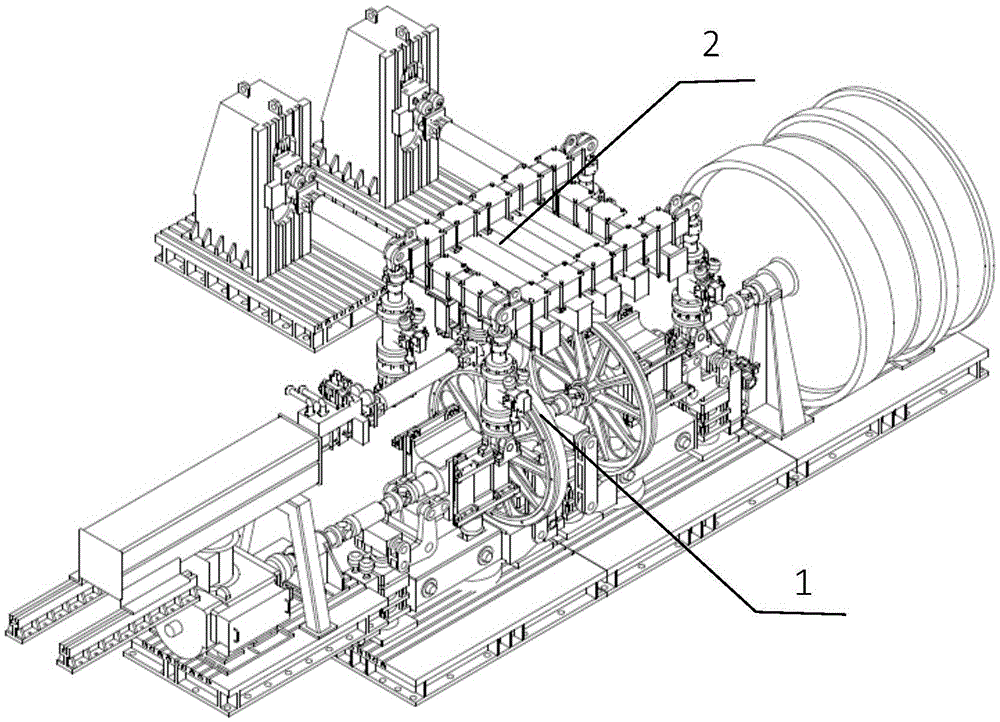

InactiveCN105628410AMake up for deficienciesHigh simulationRailway vehicle testingTruckPower steering

The present invention relates to a high-speed wheel-rail relation reliability test bed. The high-speed wheel-rail relation reliability test bed comprises a rail wheel motion device and a power truck simulation loading framework, wherein two unilateral shafts of the rail wheel are respectively connected with number 1 roller linkage transmission shaft assembly body and a number 3 roller linkage transmission shaft assembly body; the power truck simulation loading framework includes a counter-force square tube beam frame vibration excitation device, a bearing frame-type support assembly body, a number 1 counter-force base fixed device and a number 2 counter-force base fixed device; the counter-force square tube beam frame vibration excitation device, the number 1 counter-force base fixed device and the number 2 counter-force base fixed device are respectively fixedly connected with globe joint bearing block assembly bodies of the numbers 1-3, the loading framework side beams of the side beam clamping plate assembly bodies of the numbers 1-2; and the outer sides of a number 5 spherical guide strip and a number 6 spherical guide strip are fixedly connected at the inner side of the number 1 bearding frame-type support. According to the invention, the problem is solved that a train is difficult to perform the wheel rail relation reliability test in the process of actual operation in the prior art, and the requirement of the reliability parameter detection of a rail vehicle wheel in a plurality of operation conditions is satisfied.

Owner:JILIN UNIV

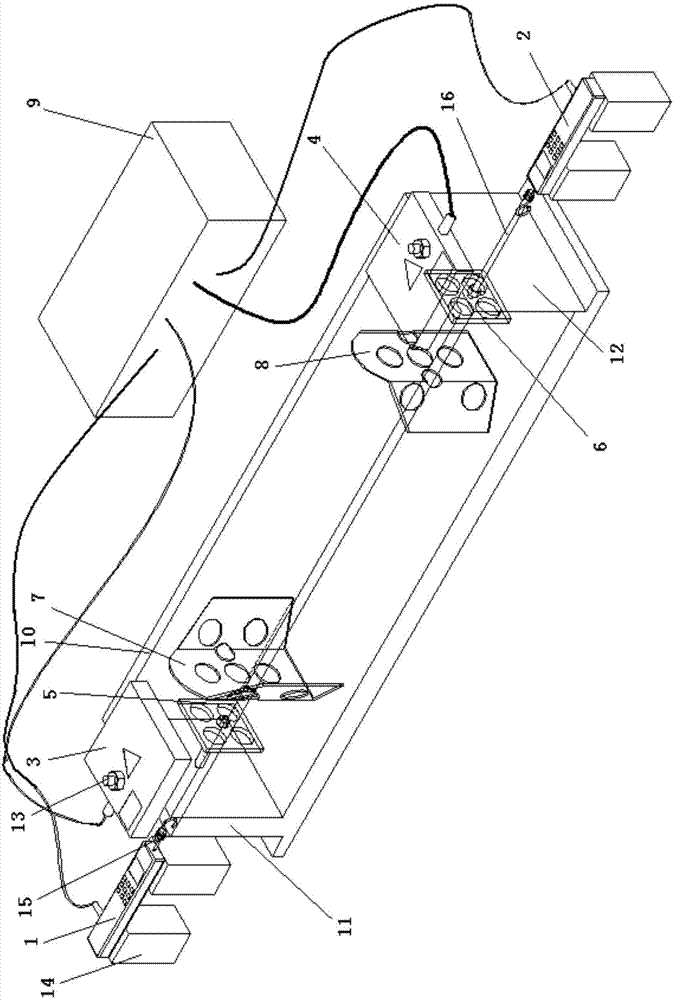

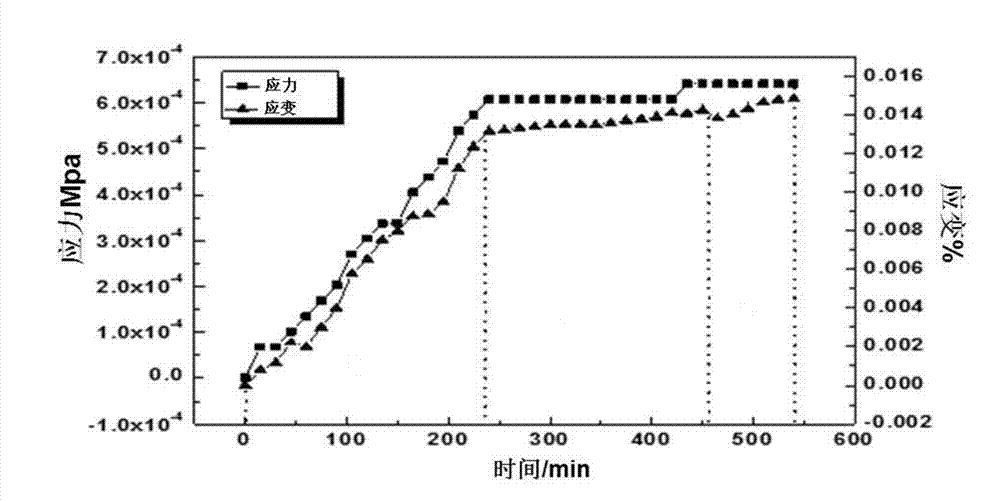

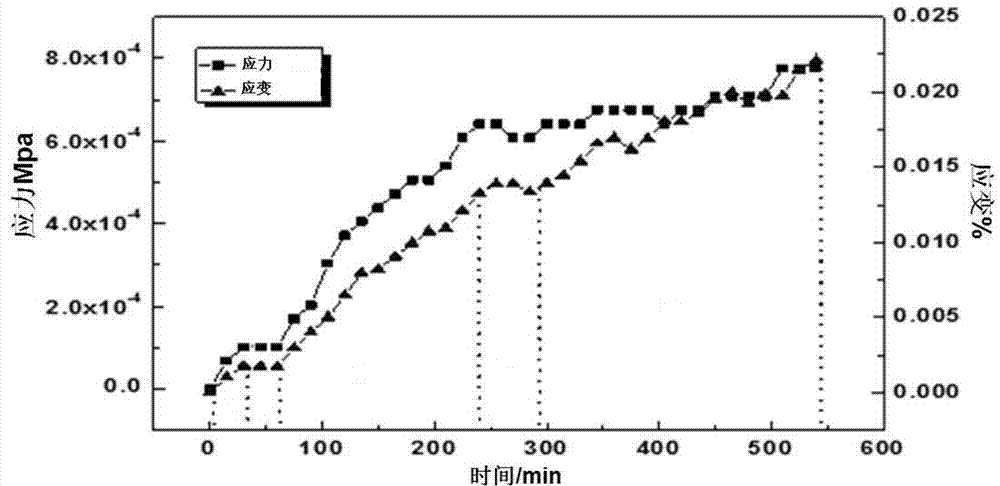

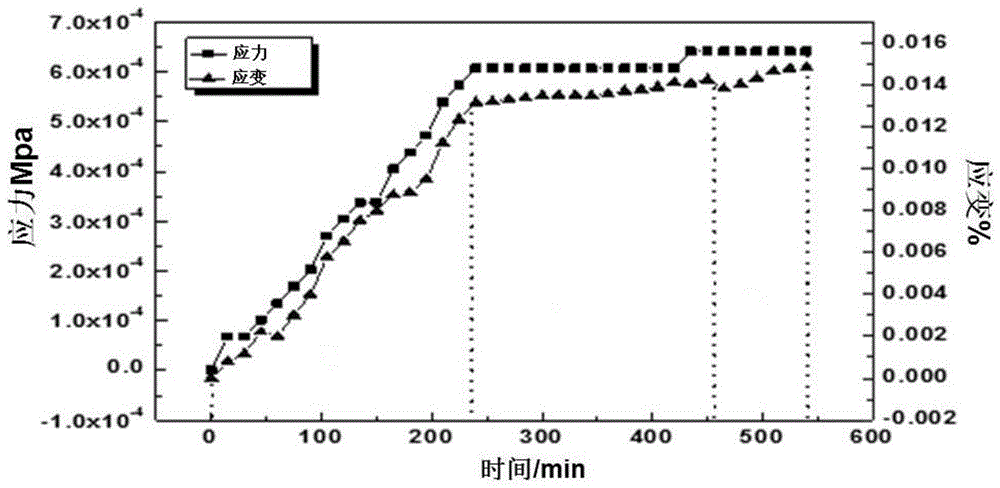

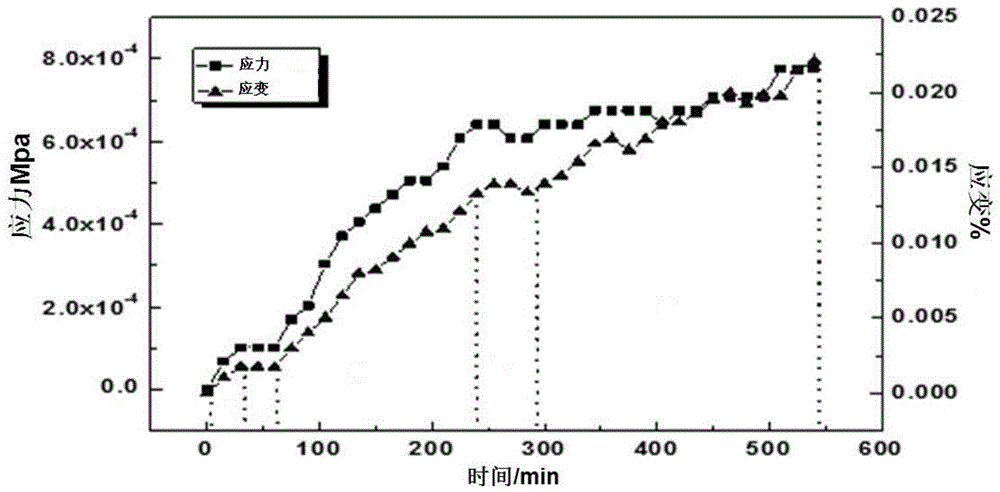

Device for testing stress-strain of plastic concrete/mortar and use method of device

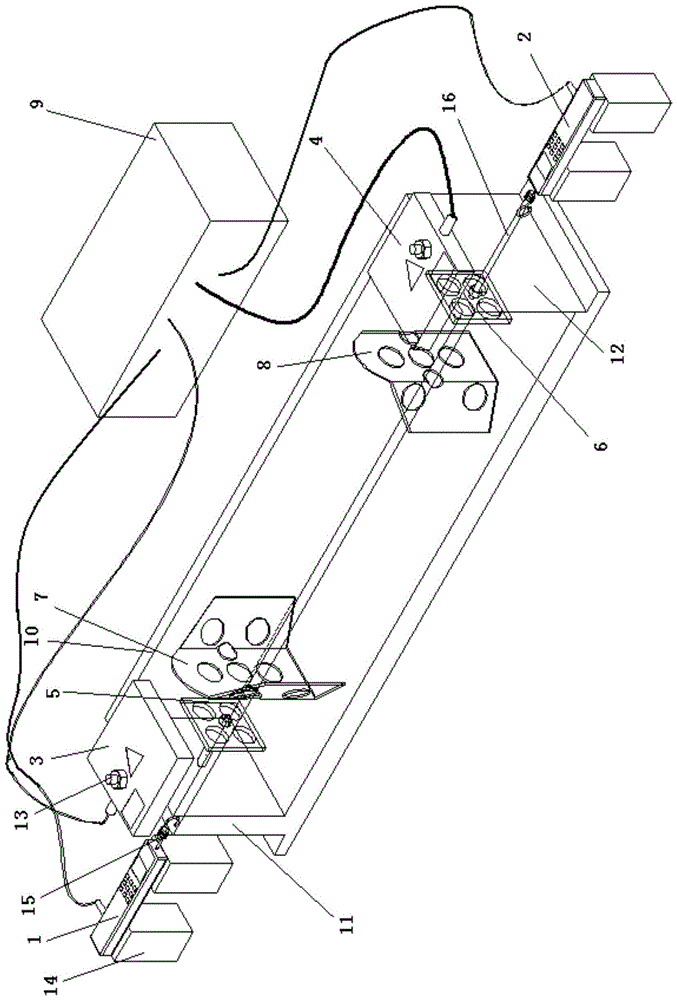

ActiveCN104280290AExcellent R&D performanceGood test foundationUsing optical meansApparatus for force/torque/work measurementLaser targetClassical mechanics

The invention relates to a device for testing stress-strain of plastic concrete / mortar. The device comprises a forcemeter a, a forcemeter b, a laser displacement sensor c, a laser displacement sensor d, a force transmission unit, a laser target unit, a data acquirer and a die, wherein the forcemeter a and the forcemeter b are respectively arranged on the left side and the right side of the die; the laser target unit and the force transmission unit are arranged in an inner cavity of the die; the laser displacement sensor c and the laser displacement sensor d are respectively arranged at the left end and the right end of the top of the die; the data acquirer is connected with the laser displacement sensor c and the laser displacement sensor d respectively through circuits. Compared with the prior art, the device disclosed by the invention is simple in structure, convenient to operate and high in test precision, can automatically and continuously test the stress and the strain in the concrete / mortar in any stage from the moment of pouring, and the practicability is high.

Owner:TONGJI UNIV

High-speed train swing-type transmission system assembly reliability testbed

InactiveCN103616178ATruly reflect the status of fatigue damageGood test foundationMachine gearing/transmission testingRailway vehicle testingLeft halfMechanical engineering

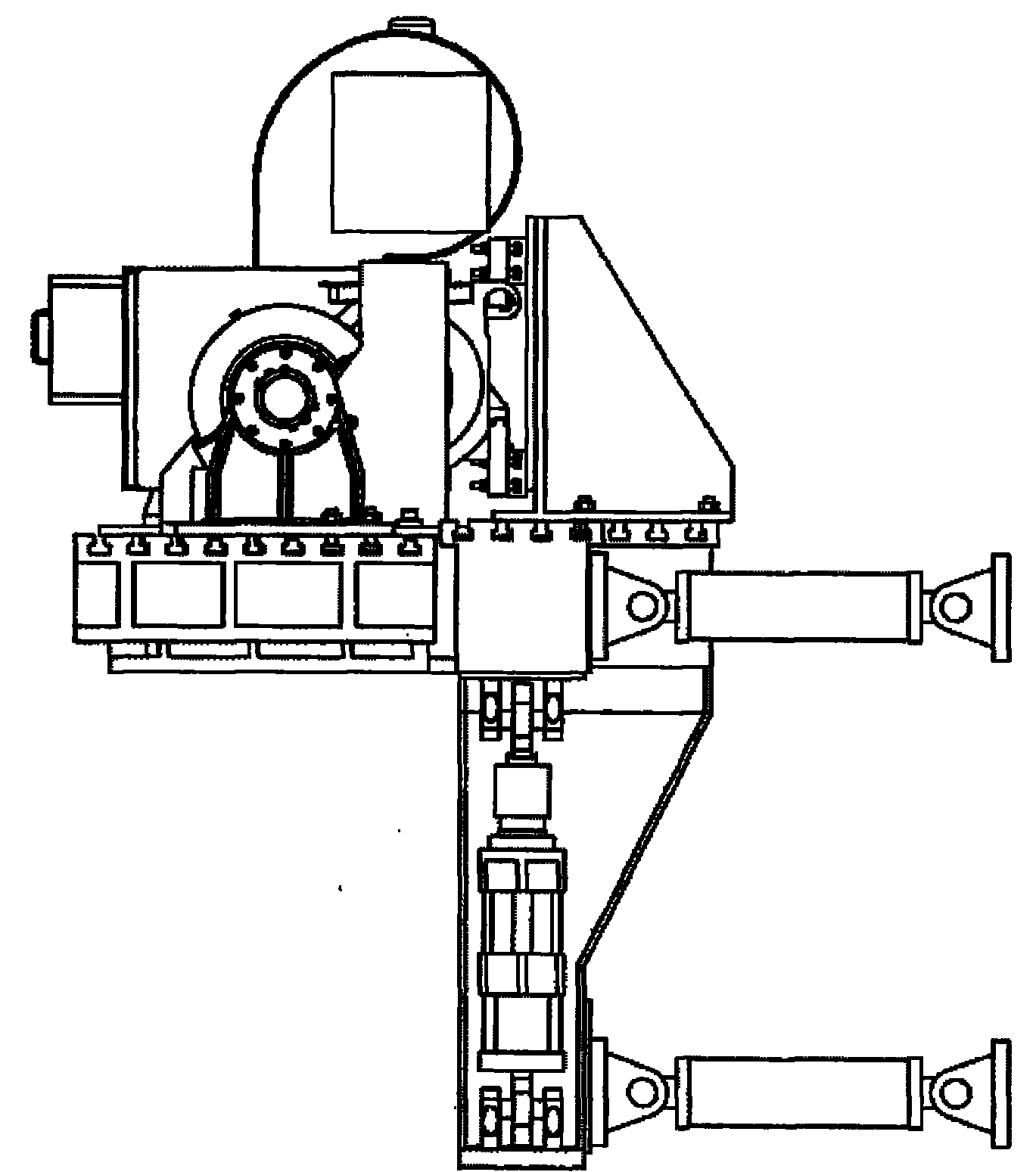

The invention discloses a high-speed train swing-type transmission system assembly reliability testbed which solves the problem that in the prior art, a transmission system is placed in a static environment, and a gear box assembly or a dragging motor is respectively researched. The high-speed train swing-type transmission system assembly reliability testbed comprises a torque detecting test device and a transmission system assembly test device. A dragging motor and gear box assembly fixing device in the transmission system assembly test device comprises a high-speed train gear box fixing supporting assembling body which comprises a gear box fixing supporting base, a gear box C-shaped clamp bearing shaft assembly and a gear box C-shaped hanging frame assembling body. The left half part of the gear box C-shaped clamp bearing shaft assembly is horizontally placed at the upper end of a vertical stand column in the gear box fixing supporting base and is fixed on the two sides of the vertical stand column through T-shaped bolts, and the right half part of the gear box C-shaped clamp bearing shaft assembly is in rotating connection with the gear box C-shaped hanging frame assembling body through a gear box C-shaped clamp bearing shaft hinge pin shaft.

Owner:JILIN UNIV

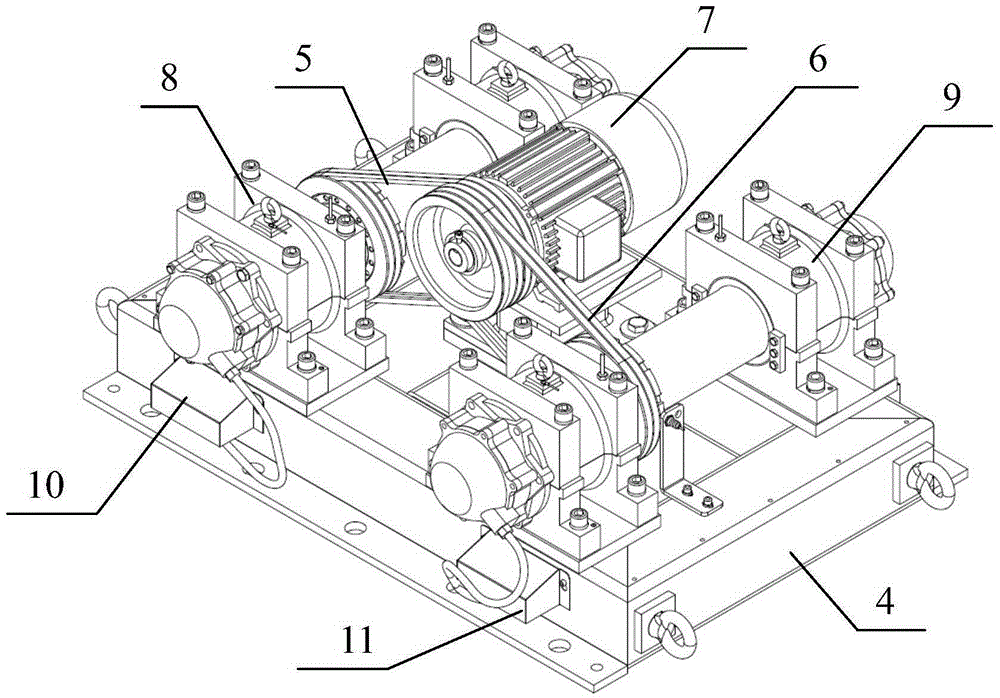

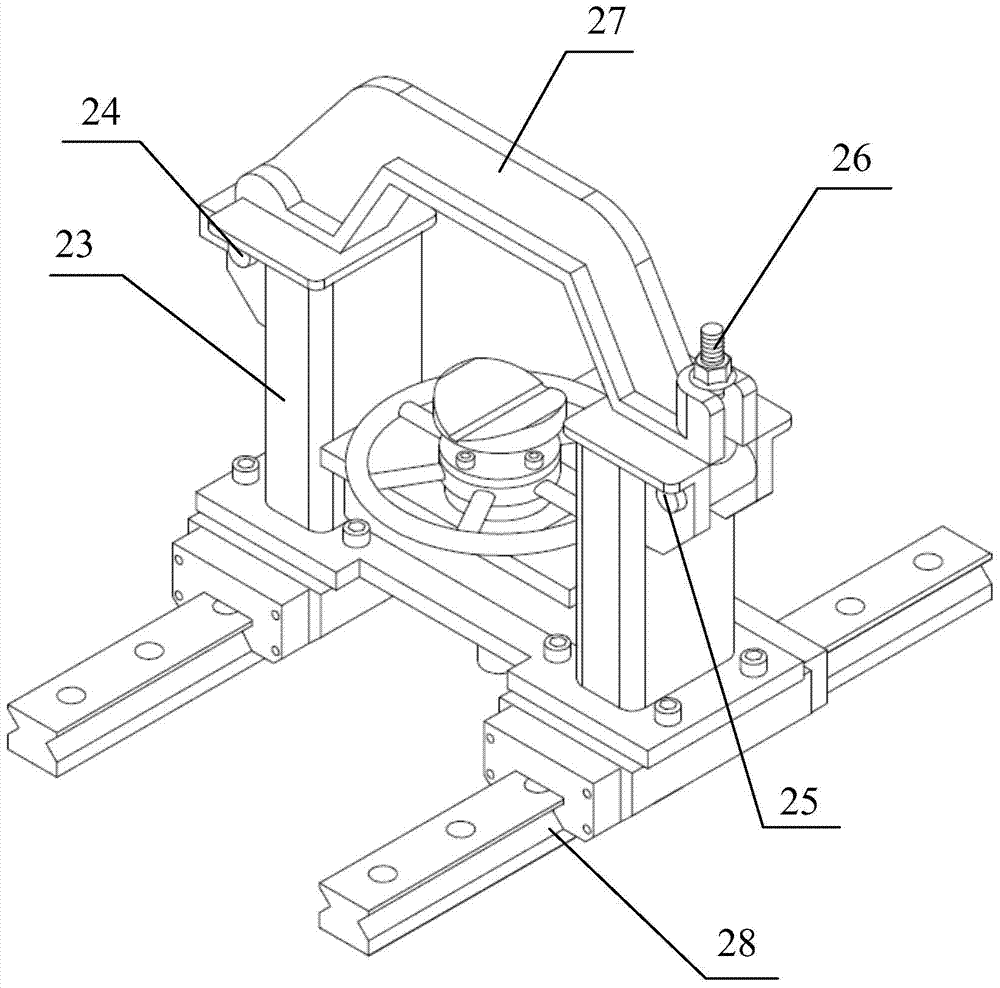

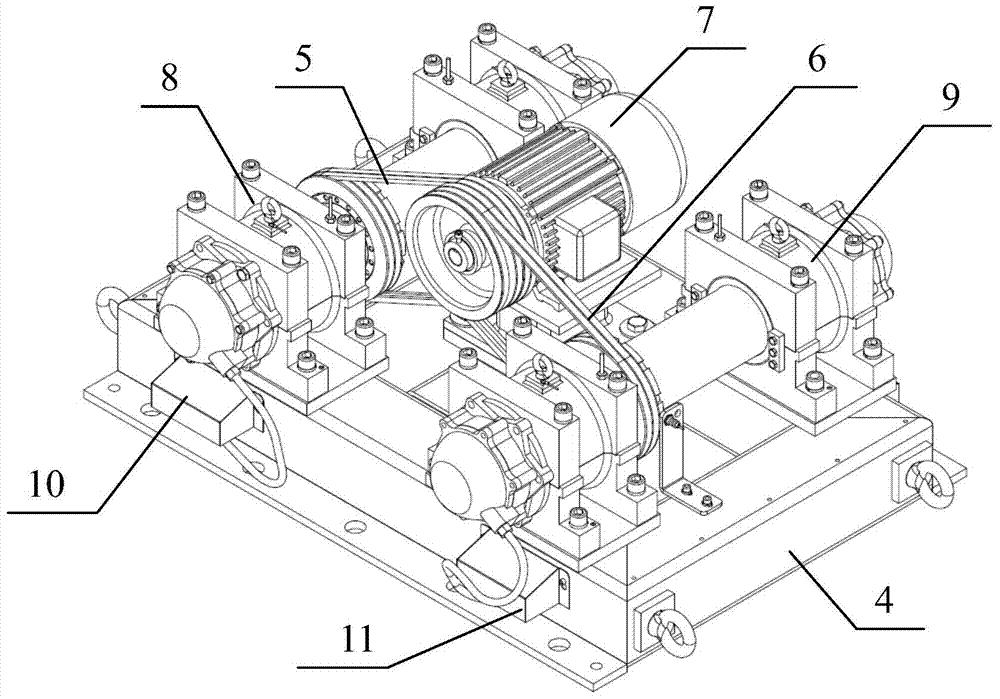

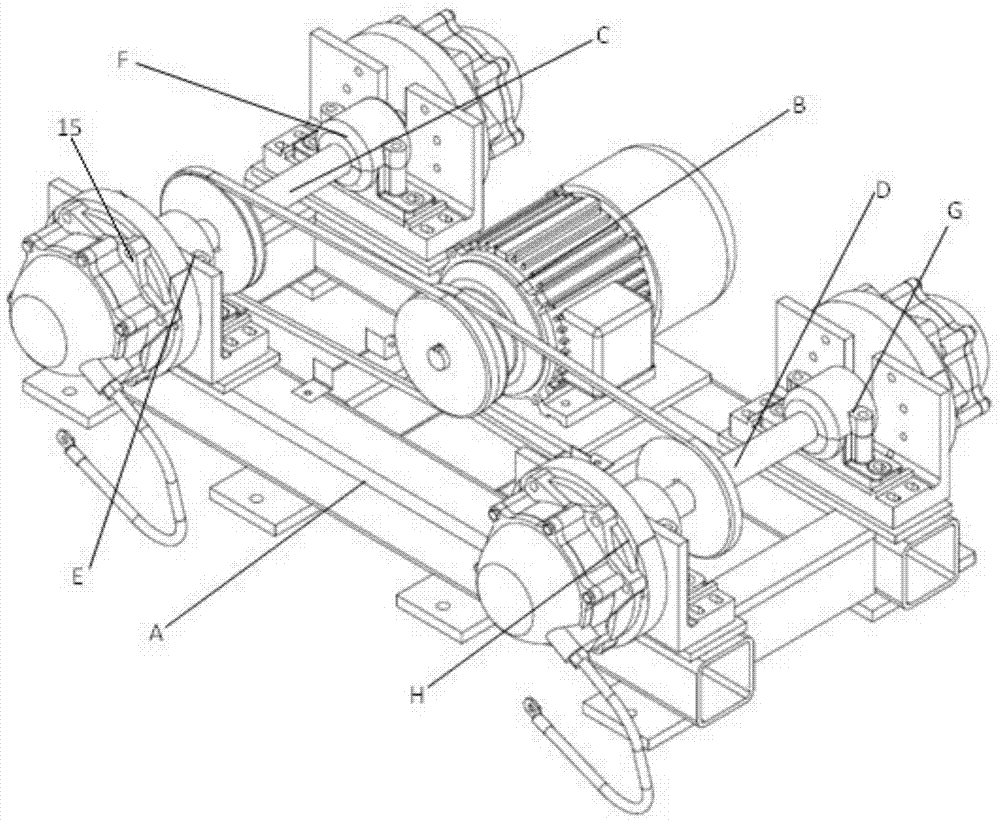

Motor train unit shaft end grounding apparatus wear test bench

The invention discloses a motor train unit shaft end grounding apparatus wear test bench. The test bench comprises a driving motor assembly fixed on a base framework and test shaft assemblies which are symmetrically arranged at the two sides of the driving motor assembly and have the same structure; each test shaft assembly is fixed on the base framework through mounting ring assemblies which are symmetrically arranged at the two ends and have the same structure; the driving motor assembly is in transmission connection with the test shaft assemblies at the two ends through a conveyor belt to form a power transmission system part of the test bench; and each test shaft assembly is composed of a test shaft, a test shaft belt pulley fixed on the test shaft and a grounding connection flange fixed at the shaft end of the test shaft. According to the invention, wear of a motor train unit in an actual working condition can be simulated, major causes of wear of a motor train unit grounding apparatus are analyzed through comparison data in case of currents and in case of no currents, and the test bench employs a reasonable mechanical structure rotating speed adjusting system and guarantees the accuracy of loss test data of the motor train unit shaft end grounding apparatus.

Owner:JILIN UNIV

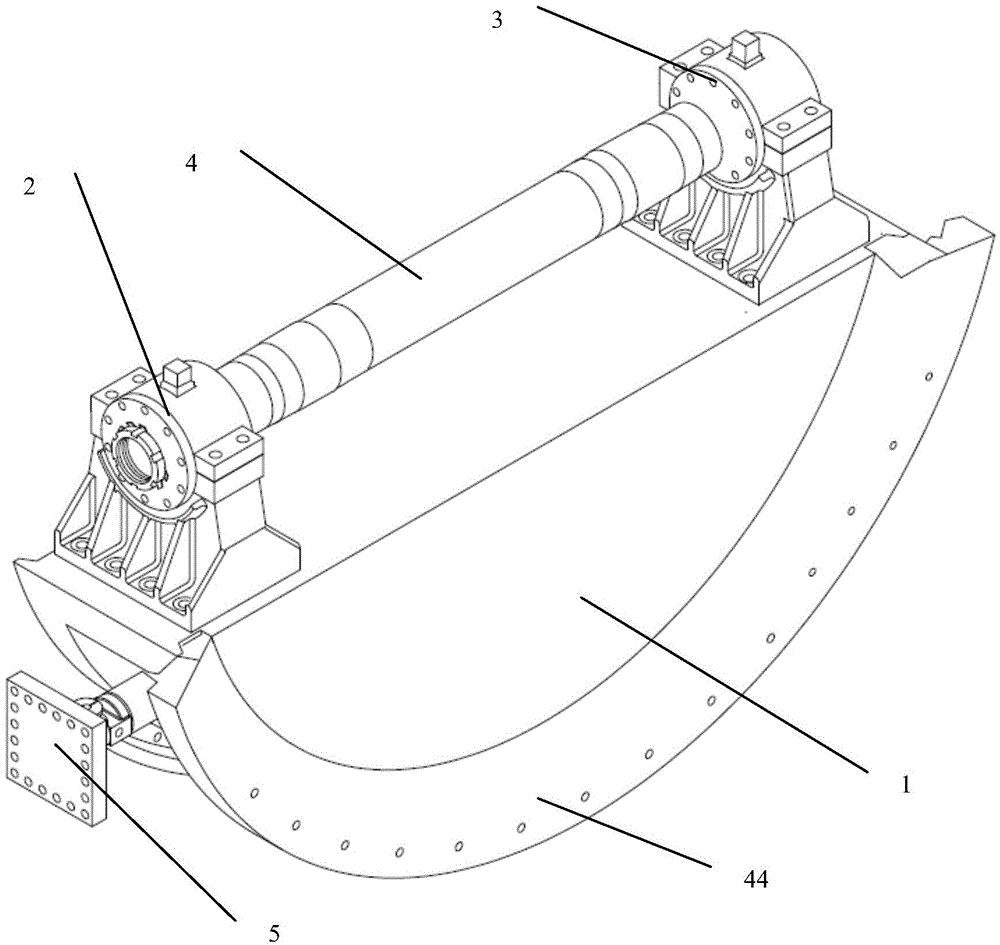

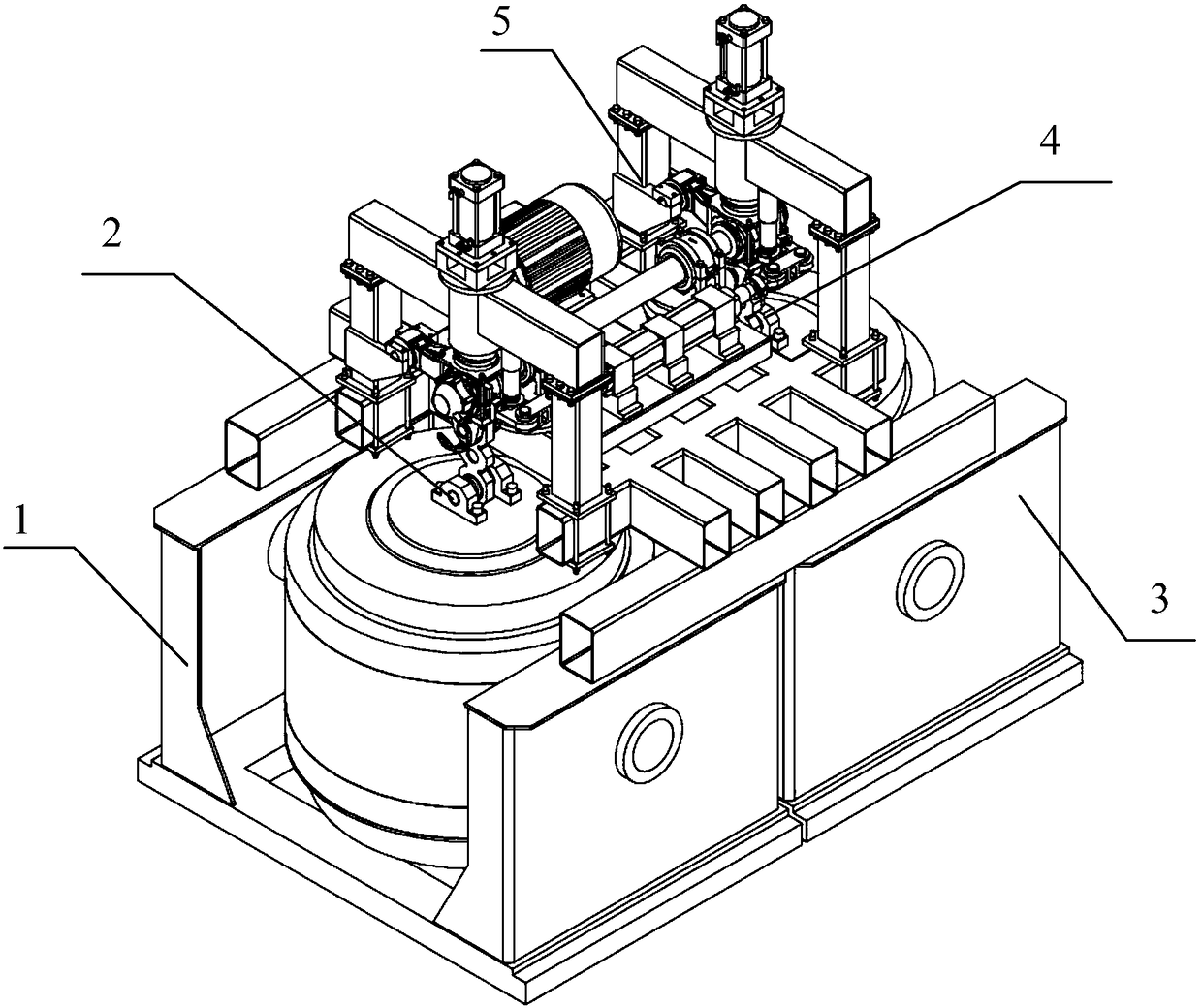

Test bench for reliability of U-shaped desk-type transmission system of gear box of motor train unit

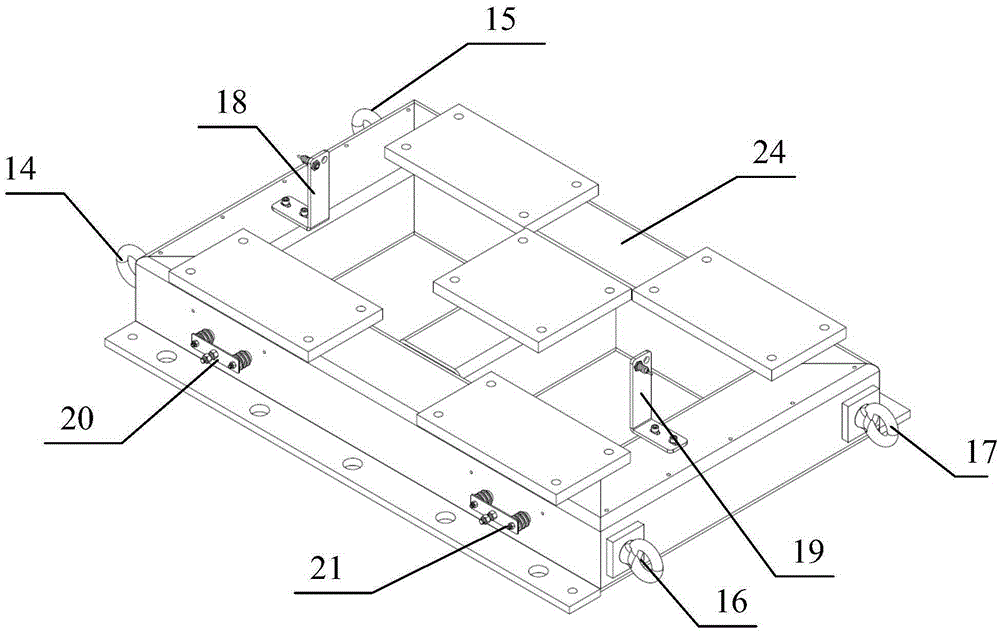

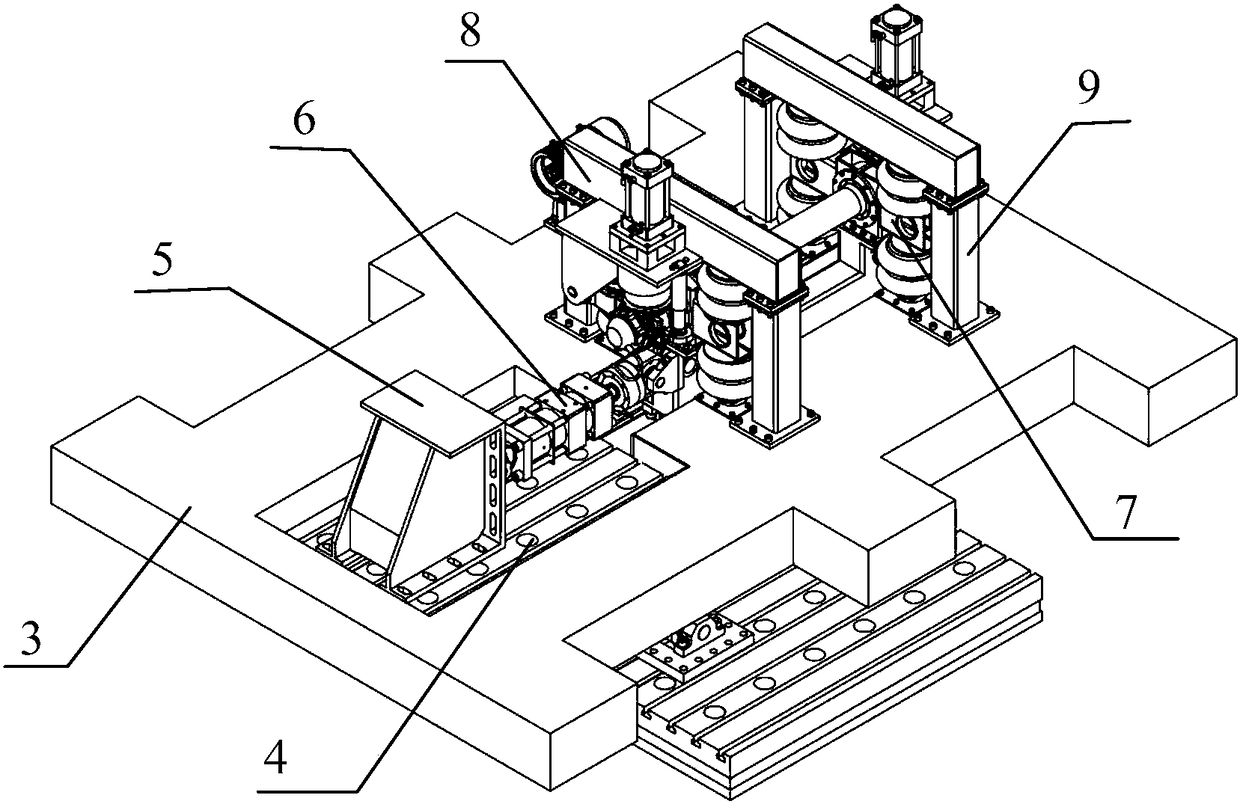

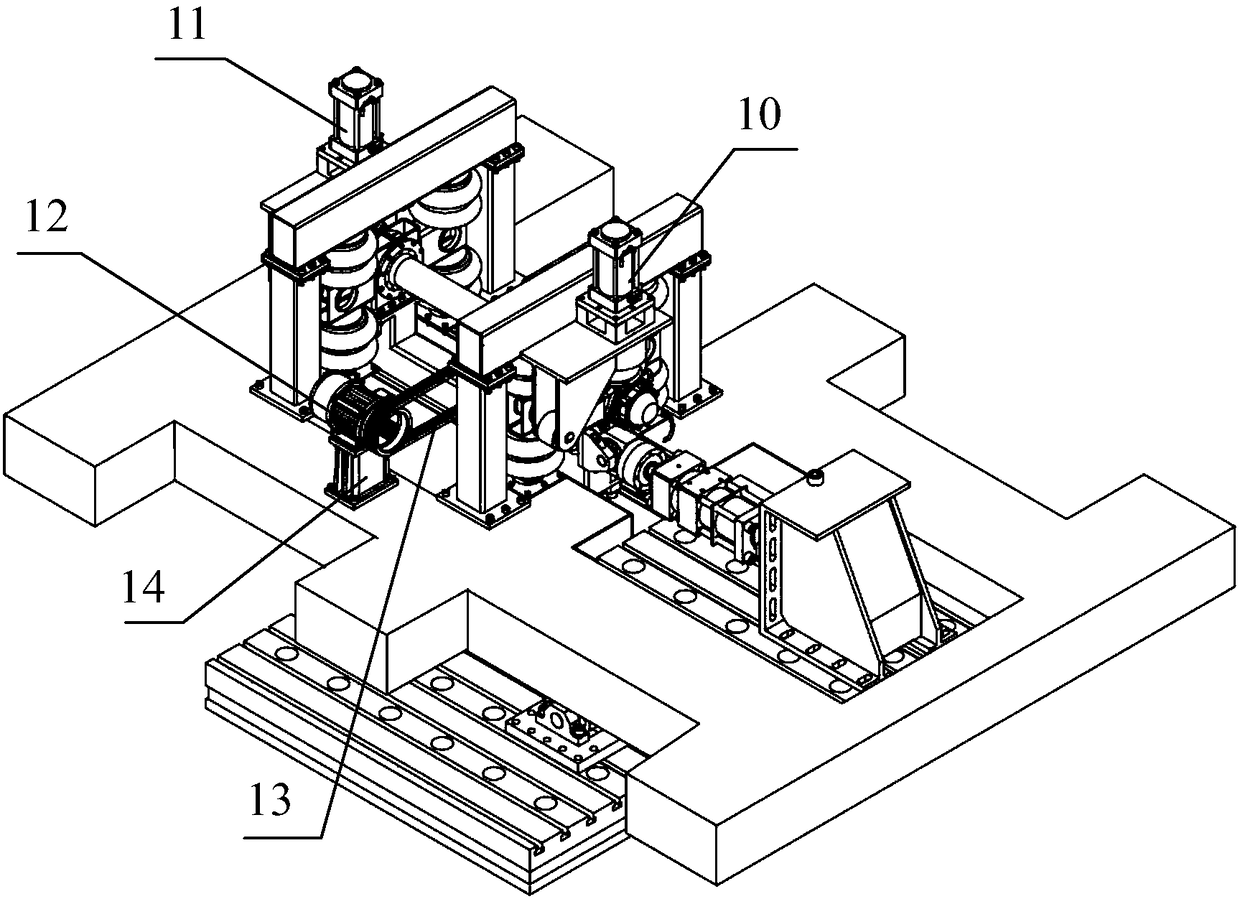

InactiveCN104865070ASolve infeasible problemsSimulate Vibration SituationsMachine gearing/transmission testingMachine bearings testingElectric machineTest bench

The invention discloses a test bench for the reliability of a U-shaped desk-type transmission system of a gear box of a motor train unit, and aims at solving a problem that a reliability test of a bearing of an axle box of a transmission system of the motor train unit cannot be carried out. The test bench comprises a gear box test vibration shaft assembly, a narrow U-shaped platform assembly, an arc-shaped seat assembly, a front cross-shaped guide rail supporting seat, and a rear cross-shaped guide rail supporting seat. The narrow U-shaped platform assembly is disposed on a foundation. A left arc-shaped seat assembly and a right arc-shaped seat assembly of the arc-shaped seat assembly are disposed on the foundation at two sides of the narrow U-shaped platform assembly. A U-shaped upper angle platform of the gear box test vibration shaft assembly is disposed on a narrow U-shaped platform of the narrow U-shaped platform assembly and locked. A left motor assembly and a right motor assembly of the gear box test vibration shaft assembly are sequentially connected with an inner side of the arc-shaped seat assembly. One end of the front cross-shaped guide rail supporting seat and one end of the rear cross-shaped guide rail supporting seat are disposed at the front and rear ends of a right platform. The other end of the front cross-shaped guide rail supporting seat and the other end of the rear cross-shaped guide rail supporting seat are disposed at the front and rear ends of the narrow U-shaped platform.

Owner:JILIN UNIV

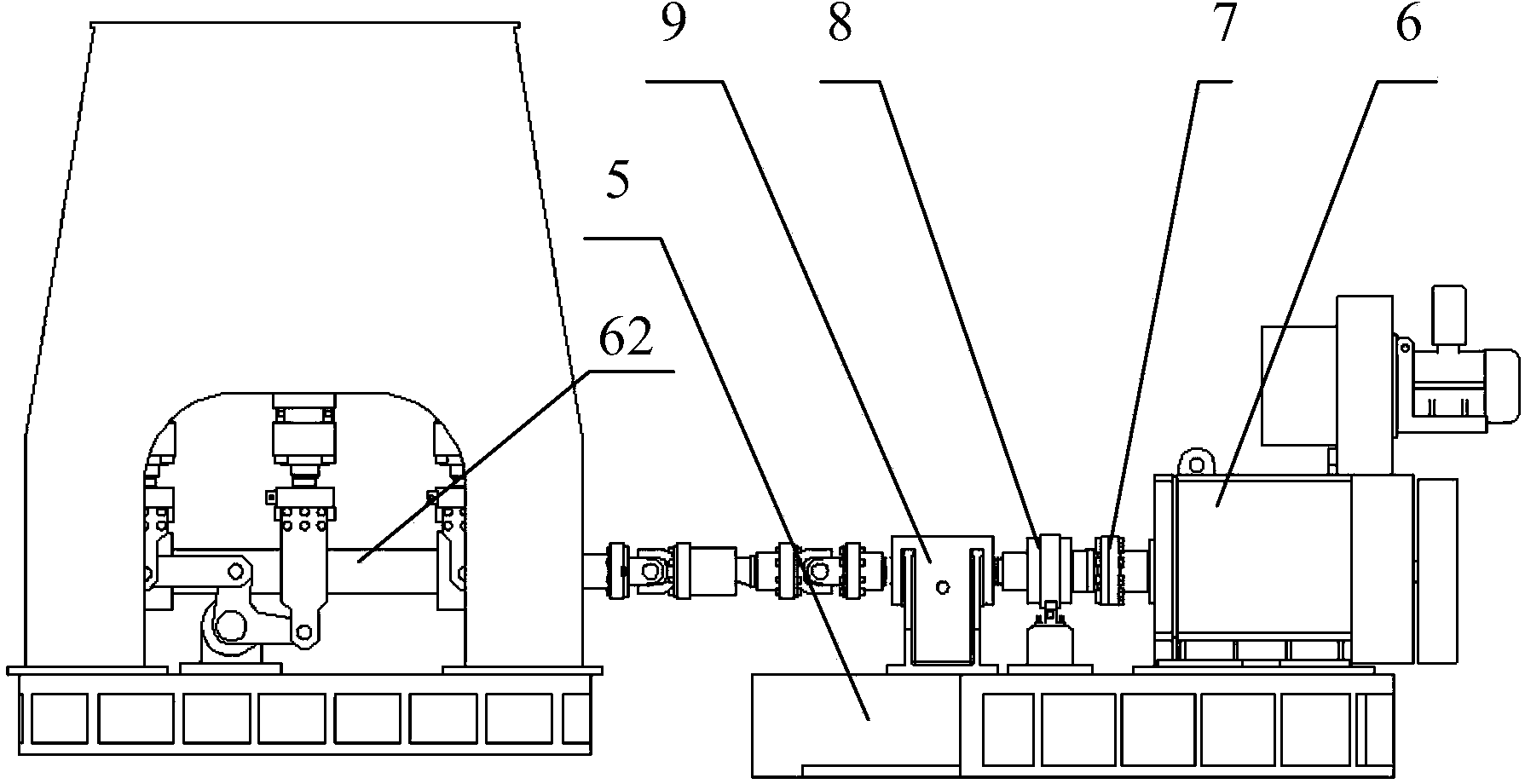

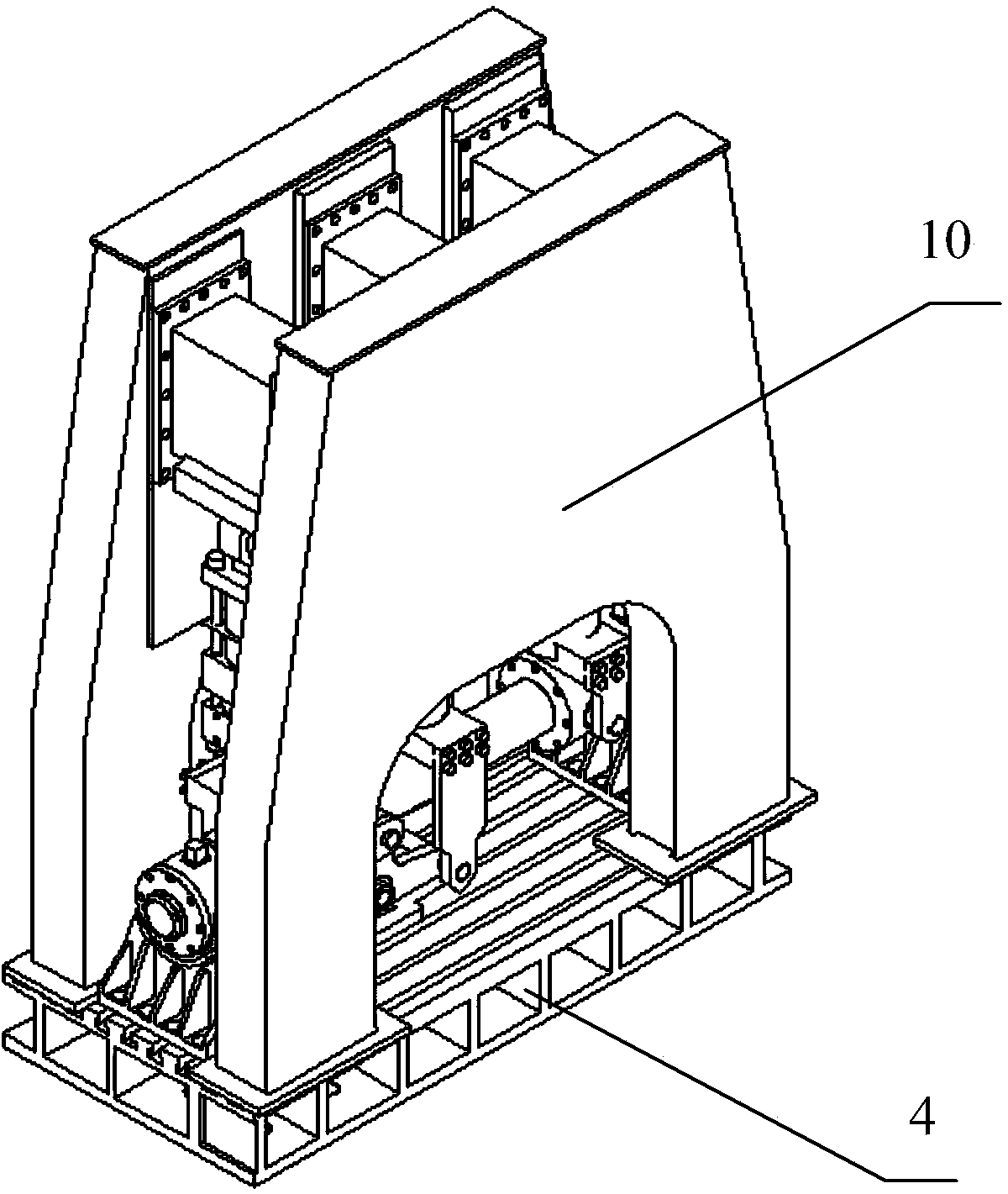

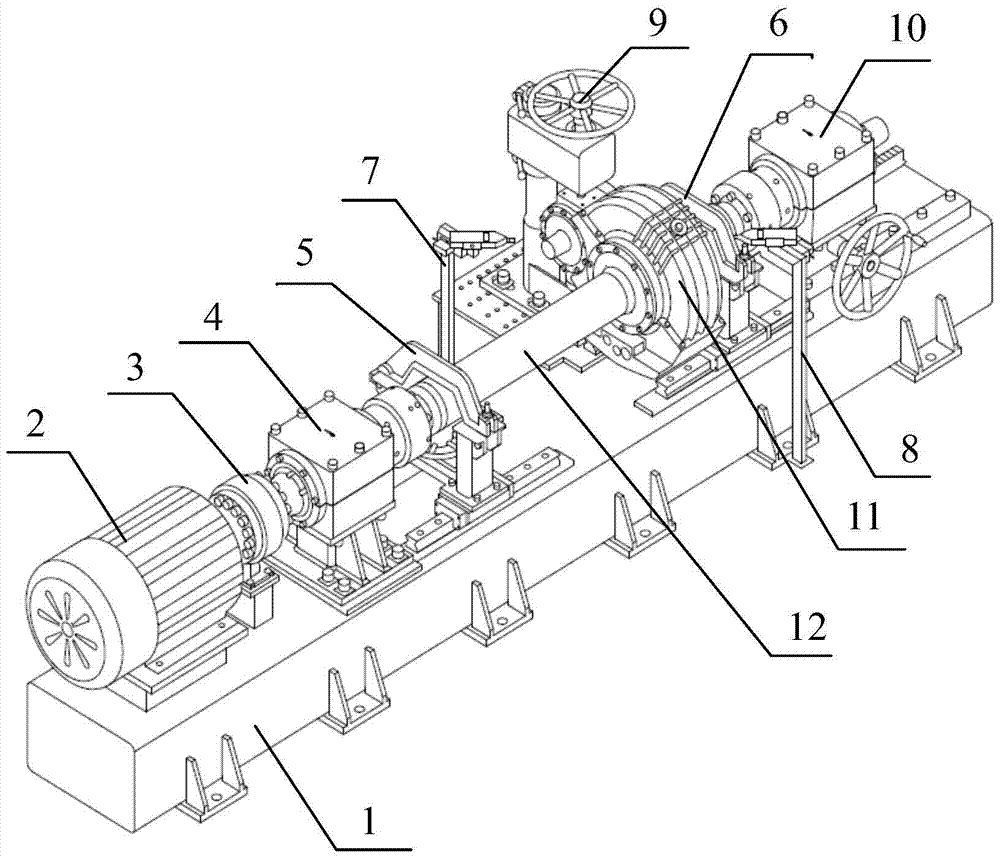

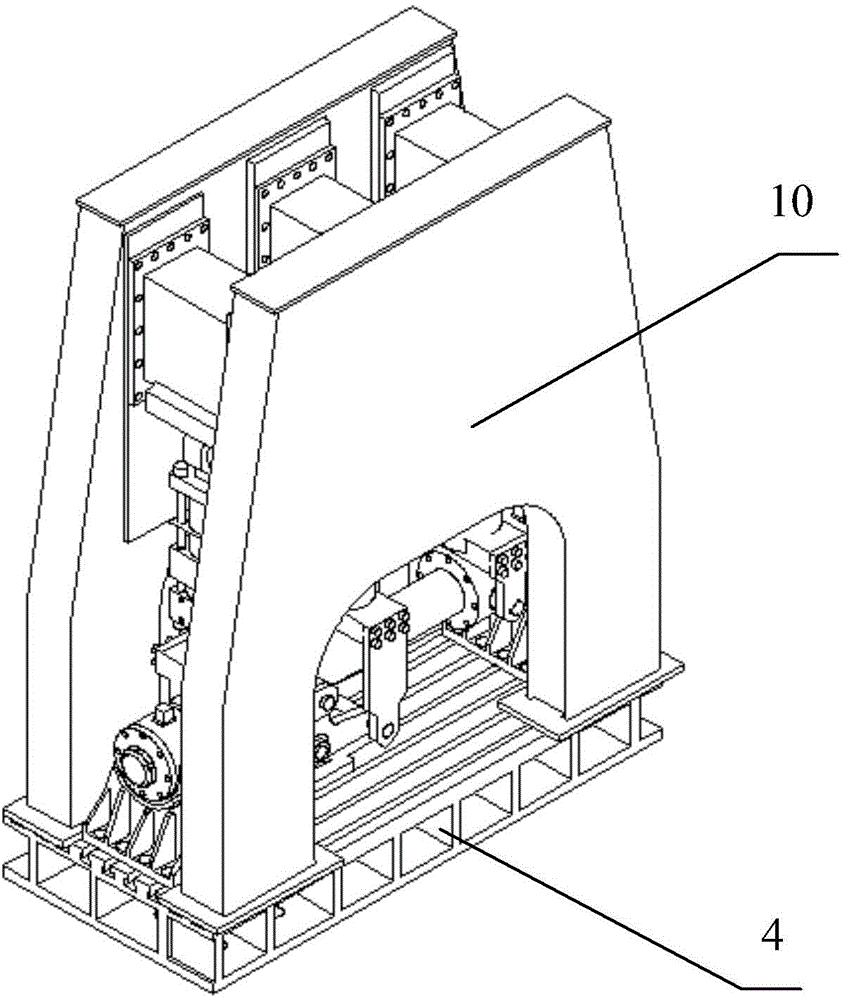

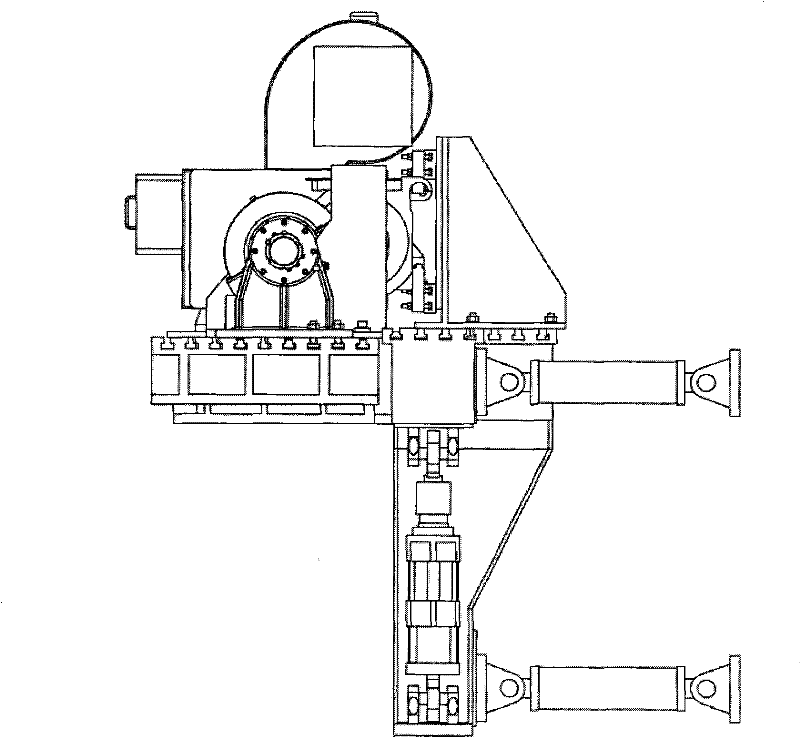

High-speed train axle box bearing gantry type counter-force frame two-dimensional excitation loading test bed

InactiveCN103630360AReduce volumeSmall footprintMachine bearings testingTransverse forceControl system

The invention discloses a high-speed train axle box bearing gantry type counter-force frame two-dimensional excitation loading test bed and aims to solve the problem that axle box bearing reliability tests cannot be performed under the actual operation working condition of trains in the prior art. The test bed comprises a axle box bearing vertical-transverse excitation device, a torque detecting and testing device and a hydraulic control system. The axle box bearing vertical-transverse excitation device comprises a rectangular bearing platform, an actuator counter-force frame, a first axle box bearing vertical force applying device, a second axle box bearing vertical force applying device, an axle box bearing transverse force applying device and an axle box bearing testing device. The axle box bearing testing device is fixed on the upper surface of the rectangular bearing platform. The first axle box bearing vertical force applying device, the second axle box bearing vertical force applying device and the axle box bearing transverse force applying device are sleeved on the axle box bearing testing device. In addition, the axle box bearing transverse force applying device is fixed on the upper surface of the rectangular bearing platform at the same time.

Owner:JILIN UNIV

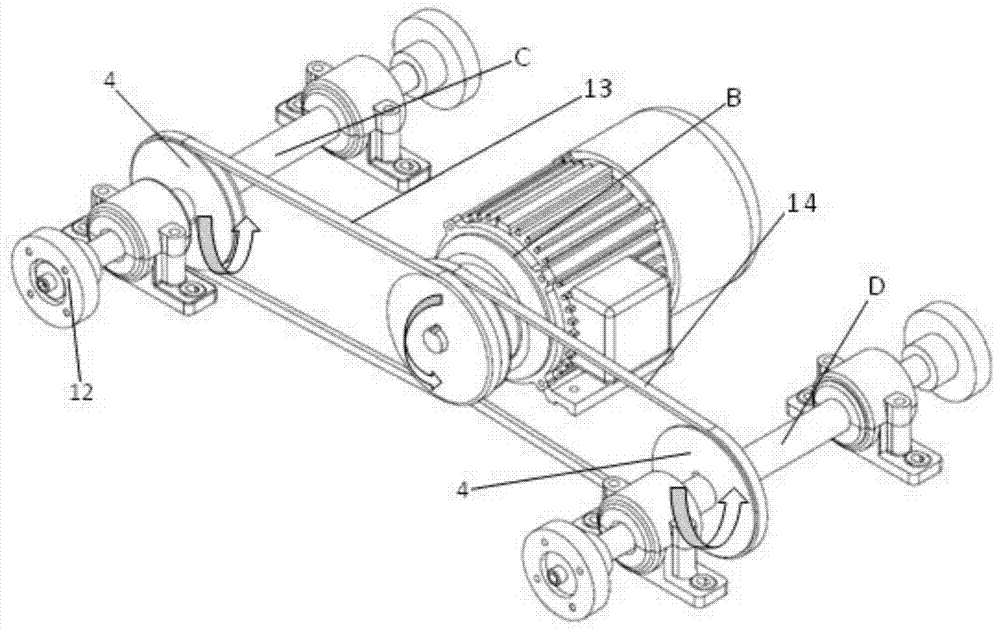

Rail vehicle axle box bearing and earthing device reliability testing stand

The invention relates to the rail vehicle axle box bearing and an earthing device reliability testing stand; the testing stand mainly comprises a transverse and vertical exciting apparatus, an exciting beam and support seat assembling body, a testing bearing assembling body, a motor and motor support pole assembling body; the exciting beam and support seat assembling body comprises an exciting beam support seat, a vertical exciting beam, and a testing vibration crossbeam; the motor and motor support pole assembling body is fixed on the exciting beam support seat; the testing bearing assembling body is fixed on the testing vibration crossbeam; the testing bearing assembling body and the motor and motor support pole assembling body are rotatably connected through a conveyer belt. The testing stand is simple in structure, can simulate the running speed and vibration conditions of the rail vehicle axle box bearing and earthing device on a real route, can provide a true and reliable testing environment for a stand test, thus solving the problems that the rail vehicle cannot have the rail motor coach axle box bearing and earthing device reliability test in real operation.

Owner:JILIN UNIV

Electric power open loop hanging type transmission system reliability test stand

InactiveCN105043757AReduce volumeSmall footprintMachine gearing/transmission testingElectric machineryDrive motor

The invention discloses an electric power open loop hanging type transmission system reliability test stand in order to overcome a problem that a motor train unit cannot conduct a motor train unit transmission system reliability test in the actual running process. The electric power open loop hanging type transmission system reliability test stand comprises a transmission system vertical vibration excitation device, a transmission system transverse vibration excitation device, a hanging support device, a gear box power open loop hanging vibration excitation assembly, a torque detection test device and an installation platform, and is characterized in that the transmission system vertical vibration excitation device is located at the right side of the installation platform; the hanging support device is installed on the transmission system vertical vibration excitation device, a simulated high-speed motor train transmission system assembly in the gear box power open loop hanging vibration excitation assembly is installed on a hanging basket in the hanging support device, two U-shaped bases are installed at the left side and the right side of the simulated high-speed motor train transmission system assembly respectively, a driving motor and the transmission system transverse vibration excitation device are located at the left side of the installation platform, and an electric eddy current dynamometer is installed on the ground; and the torque detection test device is installed on the installation platform at the front side and the rear side of the simulated high-speed motor train transmission system assembly.

Owner:JILIN UNIV

No-load running-in test bench for high-speed train gearbox

InactiveCN105466683BSafe and secure clampingEfficient deliveryMachine gearing/transmission testingRailway vehicle testingMobile endSound level meter

The invention relates to a high-speed train gearbox no-load running-in test bench, which is composed of a driving device, axle end transition bearing positioning clamping devices, a large-span mobile wheel set axle positioning supporting device, a gearbox input end pressing vertical column device and a noise testing device, wherein the driving device is arranged at the left end of a test bench base (1); a fixing-end and a mobile-end transition bearing positioning clamping devices are arranged at the left side and the right side of the test bench base (1) respectively; the large-span mobile wheel set axle positioning supporting device is composed of two sets of large-span mobile wheel set axle positioning supporting devices with the same structure; the gearbox input end pressing vertical column device is arranged on the test bench base (1); and the noise testing device comprises noise testing sound level meters and supporting tube assemblies arranged at the input end and the output end of the gearbox respectively. A series of technical problems that the existing gearbox no-load running-in test bench is complicated to assemble and disassemble, an axle journal is damaged, a high rotation speed can not be met and the like can be solved.

Owner:JILIN UNIV

High-speed EMU axle box bearing gantry-type reaction frame two-dimensional excitation loading test bench

InactiveCN103630360BReduce volumeSmall footprintMachine bearings testingTransverse forceControl system

The invention discloses a high-speed train axle box bearing gantry type counter-force frame two-dimensional excitation loading test bed and aims to solve the problem that axle box bearing reliability tests cannot be performed under the actual operation working condition of trains in the prior art. The test bed comprises a axle box bearing vertical-transverse excitation device, a torque detecting and testing device and a hydraulic control system. The axle box bearing vertical-transverse excitation device comprises a rectangular bearing platform, an actuator counter-force frame, a first axle box bearing vertical force applying device, a second axle box bearing vertical force applying device, an axle box bearing transverse force applying device and an axle box bearing testing device. The axle box bearing testing device is fixed on the upper surface of the rectangular bearing platform. The first axle box bearing vertical force applying device, the second axle box bearing vertical force applying device and the axle box bearing transverse force applying device are sleeved on the axle box bearing testing device. In addition, the axle box bearing transverse force applying device is fixed on the upper surface of the rectangular bearing platform at the same time.

Owner:JILIN UNIV

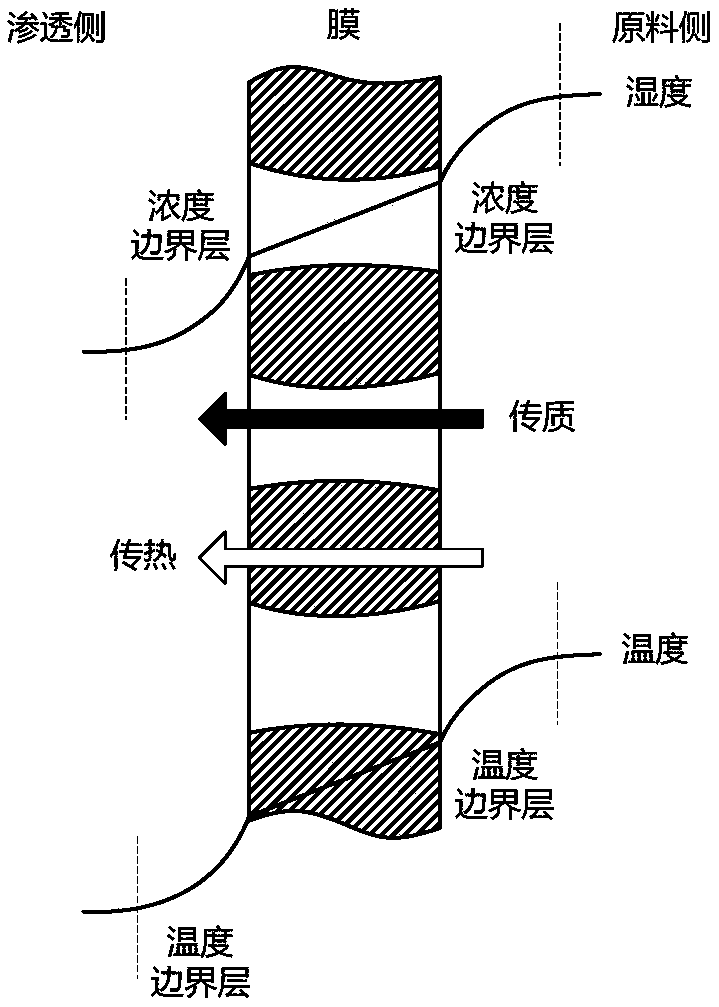

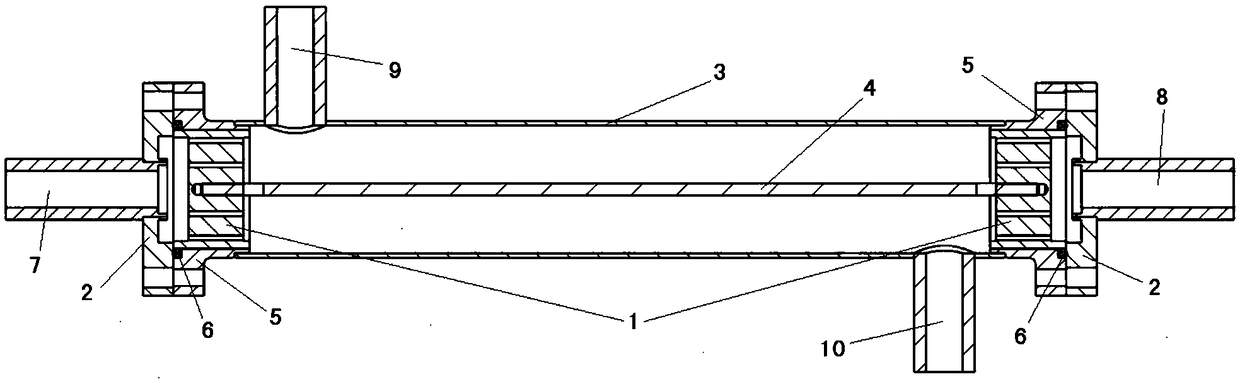

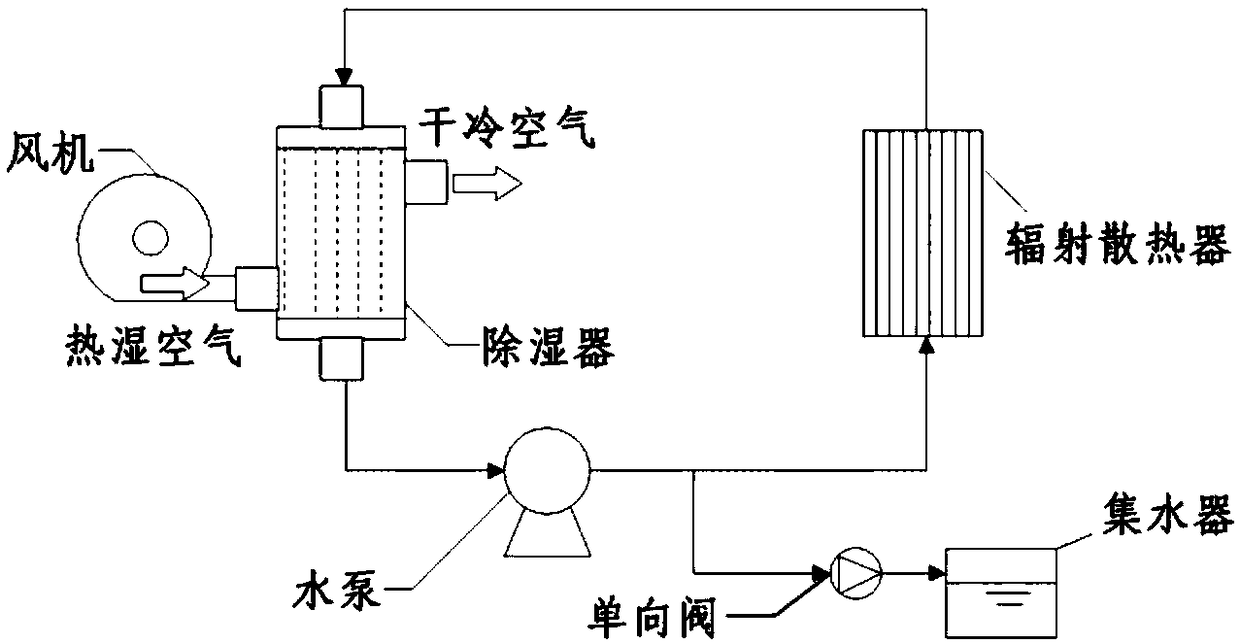

Air dehumidifier based on composite microporous membranes and dehumidifying equipment

InactiveCN108619868AAvoid enteringReduce the temperatureCosmonautic environmental control arrangementSemi-permeable membranesFiberHollow fibre

The invention discloses an air dehumidifier based on composite microporous membranes. The air dehumidifier comprises end sockets, flanges, a longitudinally long middle tube shell structure, a pillar,connectors, cold water inlet and outlet flow passages, and air inlet and outlet flow passages. The two end sockets are used for fixing two ends of each membrane filament, and are respectively connected to the cold water inlet and outlet flow passages through the connectors and the flanges so that low-temperature cold water flows into the membrane filaments. The tube shell structure contains a plurality of clustered hollow fiber composite microporous membrane filaments, and is hermetically connected to the end sockets at two sides. The pillar disposed in the center axis of the tube shell structure is a supporting structure, ensuring that the membrane filaments have sufficient mechanical strength, and that the low-temperature cold water flows into the membrane filaments, exchanges heat withhigh-temperature high-humidity air fed and discharged from the air inlet and outlet flow passages arranged on the side surface of the tube shell structure, and then is conveyed into a sealing bin foruse. According to the air dehumidifier, temperature and humidity of wet air are reduced, and under combined functions of capillary force in micropores of the membranes and the water vapor partial pressure difference, transmission of water vapor to the cold water is achieved, and the water vapor valuable in a spacecraft cabin can be directly completely recovered.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

High-speed train transmission system assembly reliability test bed

InactiveCN102095578BTruly reflect the status of fatigue damageSimulate Vibration SituationsMachine gearing/transmission testingRailway vehicle testingThree degrees of freedomCoupling

The invention discloses a high-speed train transmission system assembly reliability test bed. The test bed comprises a power transmission flexibility test device, a three-degree-of-freedom vibration simulation test device, and a high-speed train transmission system assembly reliability test device. The three-degree-of-freedom vibration simulation test device and the high-speed train transmission system assembly reliability test device are mounted on the foundation in parallel; a crossbeam of the three-degree-of-freedom vibration simulation test device and a high-speed train transmission system assembly support platform of the high-speed train transmission system assembly reliability test device have a parallel distance of 20 to 40 mm; and the upper work surface of the crossbeam and the upper work surface of the high-speed train transmission system assembly support platform are on the same horizontal plane. The three-degree-of-freedom vibration simulation test device is connected with the power transmission flexibility test device mounted on the foundation through a transverse actuator; and the power transmission flexibility test device is connected with the high-speed train transmission system assembly reliability test device through a cross-shaft type universal coupling.

Owner:JILIN UNIV

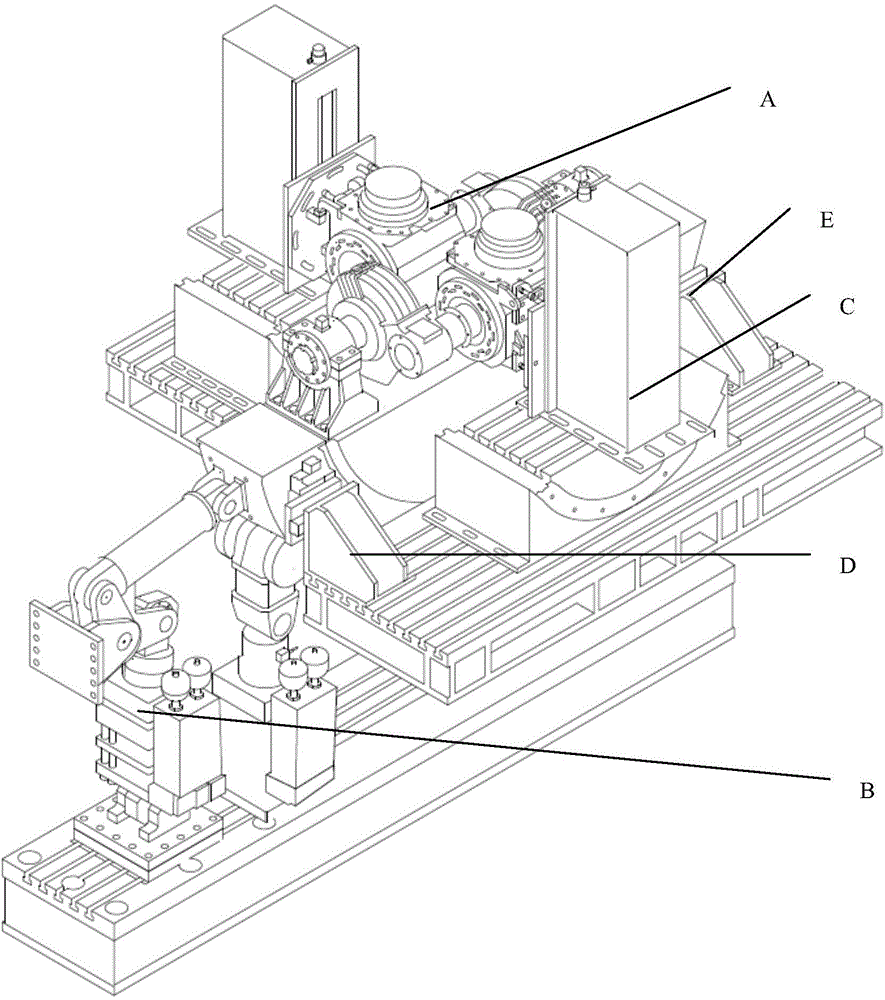

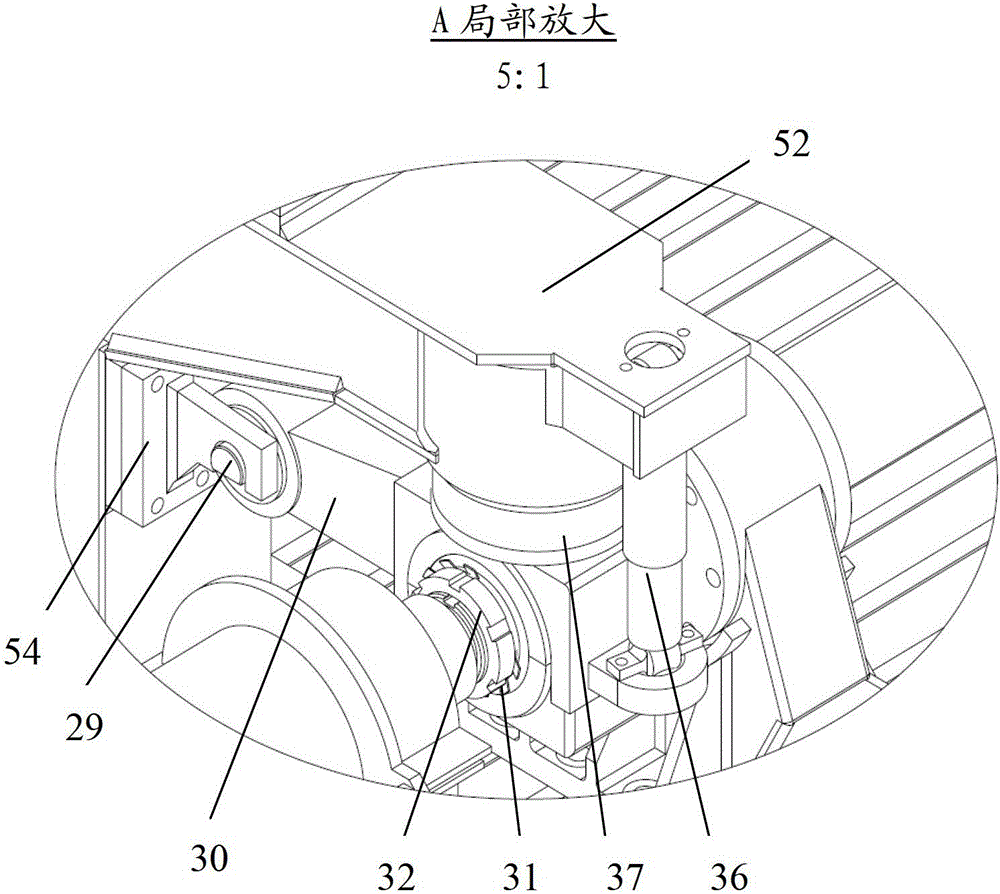

Axle box bearing comprehensive performance test bench

ActiveCN107300470BSolve the test infeasibility problemImprove safe operationMachine bearings testingEngineeringForce sensor

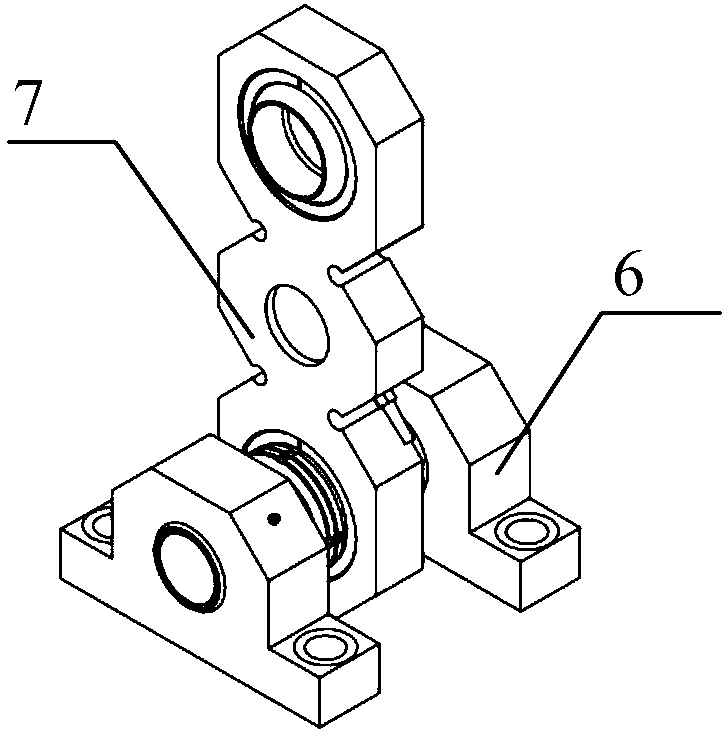

The invention relates to a shaft box bearing comprehensive property testing platform which consists of two electromagnetic vibration exciters, two vibration excitation force measuring sensor assemblies and a testing equipment assembly, wherein the two electromagnetic vibration exciters and the two vibration excitation force measuring sensor assemblies are of the same structures; the vibration excitation force measuring sensor assemblies comprise sensor hinge pin shafts and vibration excitation sensors; the sensor hinge pin shafts and the vibration excitation sensors are connected through hinge pin globe joints; the testing equipment assembly is fixed on the first and second electromagnetic vibration exciters through bolts; the lower ends of the first and second vibration excitation force measuring sensor assemblies are respectively fixed on the first and second electromagnetic vibration exciters through bolts; the upper ends of the first and second vibration excitation force measuring sensor assemblies are respectively connected with first and second shaft box excitation clamps in the testing equipment assembly through hinge pin globe joints. The shaft box bearing comprehensive property testing platform is simple in structure, speed and vibration situations of track vehicle shaft box bearings on actual routes can be simulated, testing environments are real and reliable, and the problem that the reliability of a high-speed train shaft box bearings of track vehicles cannot be tested in actual operation is solved.

Owner:JILIN UNIV

Rail vehicle axle end grounding device wear test bench

InactiveCN105403417BSolving the Infeasibility of Loss TestingGuaranteed accuracyRailway vehicle testingDoubling testPower flow

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

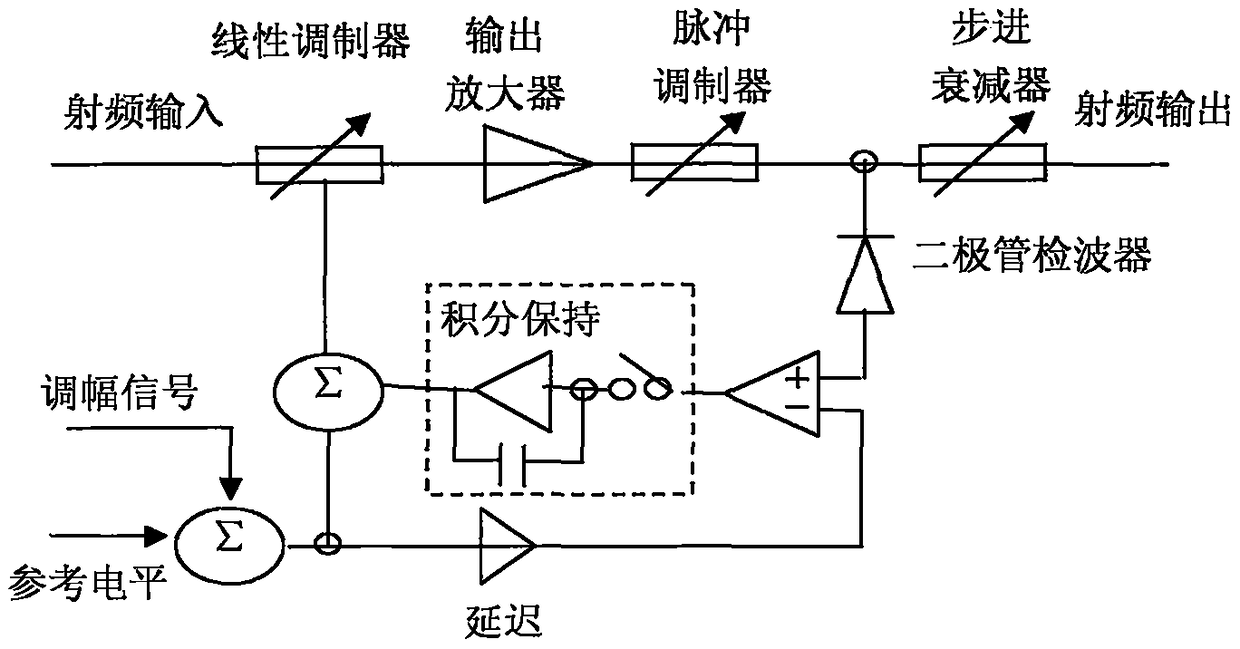

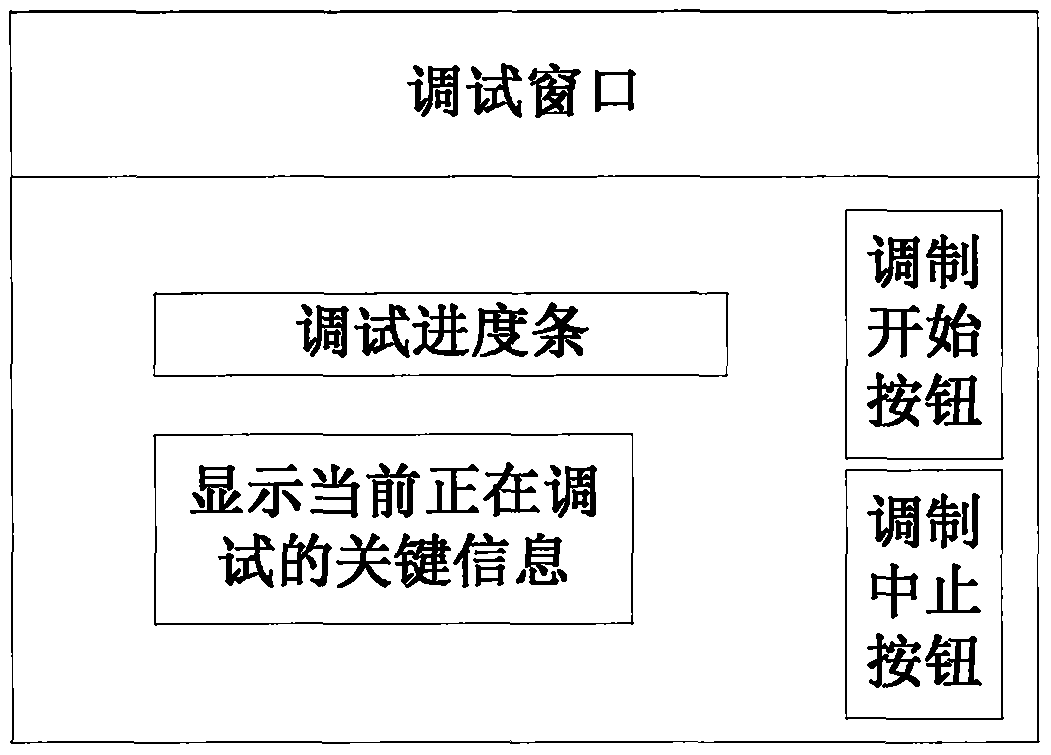

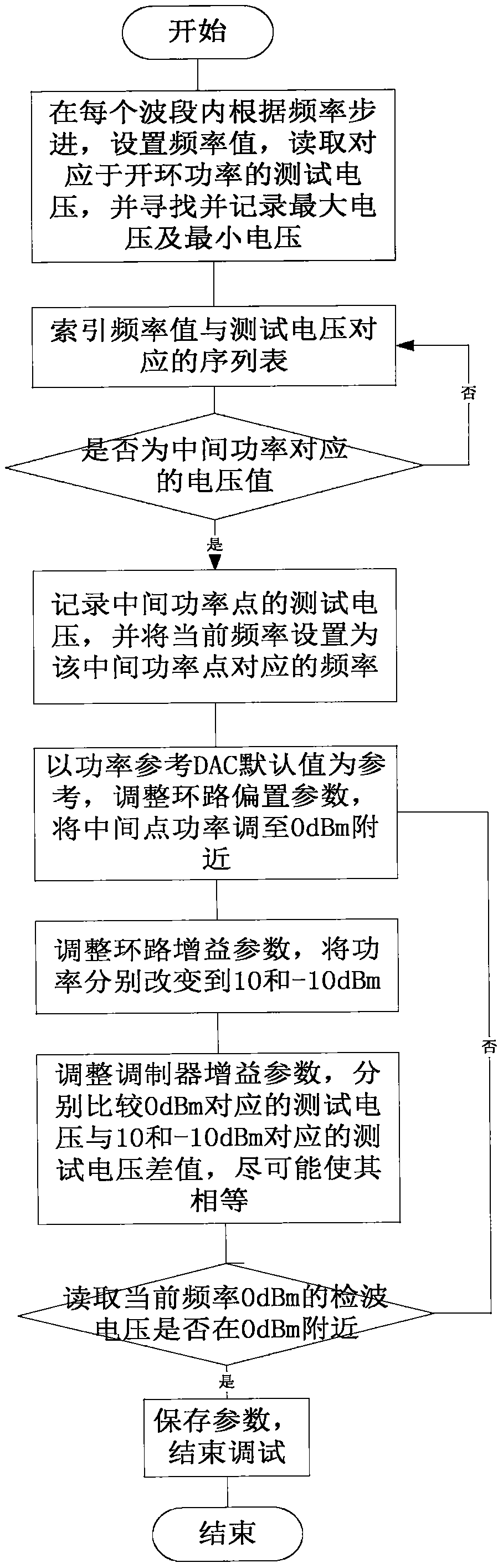

An automatic debugging method for open-loop power linearity applied to signal generators

ActiveCN105471520BGood test foundationGuaranteed linearityTransmission monitoringOperabilitySignal generator

In order to improve the accuracy of the open-loop power linearity index and improve the ease of debugging and meet the requirements of instrument productivity, the present invention proposes an automatic debugging method for the open-loop power linearity, which can make the ALC open-loop power in Under the control of the internal debugging software, by reading the internal test voltage and the corresponding algorithm, the automatic open-loop power linearity debugging can be realized, which improves the open-loop power linearity index and debugging efficiency, and effectively reduces the production cost.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

High-speed EMU oscillating drive train assembly reliability test bench

InactiveCN103616178BTruly reflect the status of fatigue damageGood test foundationMachine gearing/transmission testingRailway vehicle testingLeft halfTest bench

The invention discloses a high-speed train swing-type transmission system assembly reliability testbed which solves the problem that in the prior art, a transmission system is placed in a static environment, and a gear box assembly or a dragging motor is respectively researched. The high-speed train swing-type transmission system assembly reliability testbed comprises a torque detecting test device and a transmission system assembly test device. A dragging motor and gear box assembly fixing device in the transmission system assembly test device comprises a high-speed train gear box fixing supporting assembling body which comprises a gear box fixing supporting base, a gear box C-shaped clamp bearing shaft assembly and a gear box C-shaped hanging frame assembling body. The left half part of the gear box C-shaped clamp bearing shaft assembly is horizontally placed at the upper end of a vertical stand column in the gear box fixing supporting base and is fixed on the two sides of the vertical stand column through T-shaped bolts, and the right half part of the gear box C-shaped clamp bearing shaft assembly is in rotating connection with the gear box C-shaped hanging frame assembling body through a gear box C-shaped clamp bearing shaft hinge pin shaft.

Owner:JILIN UNIV

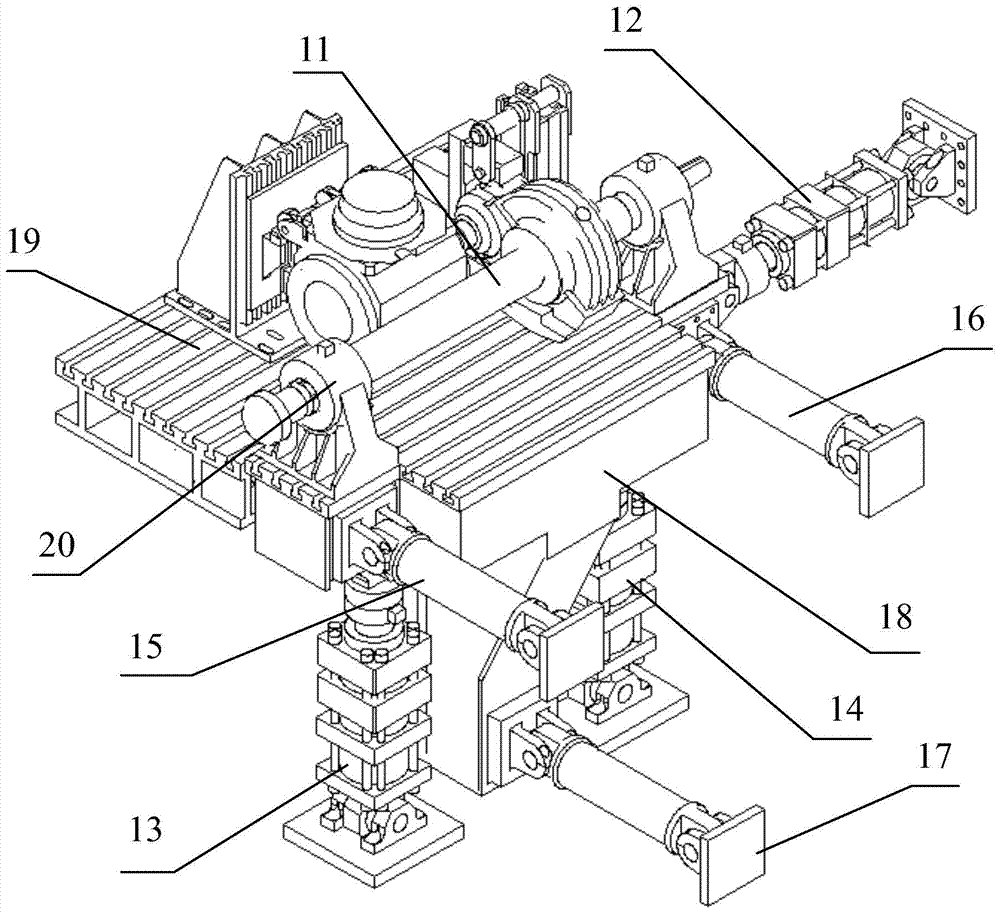

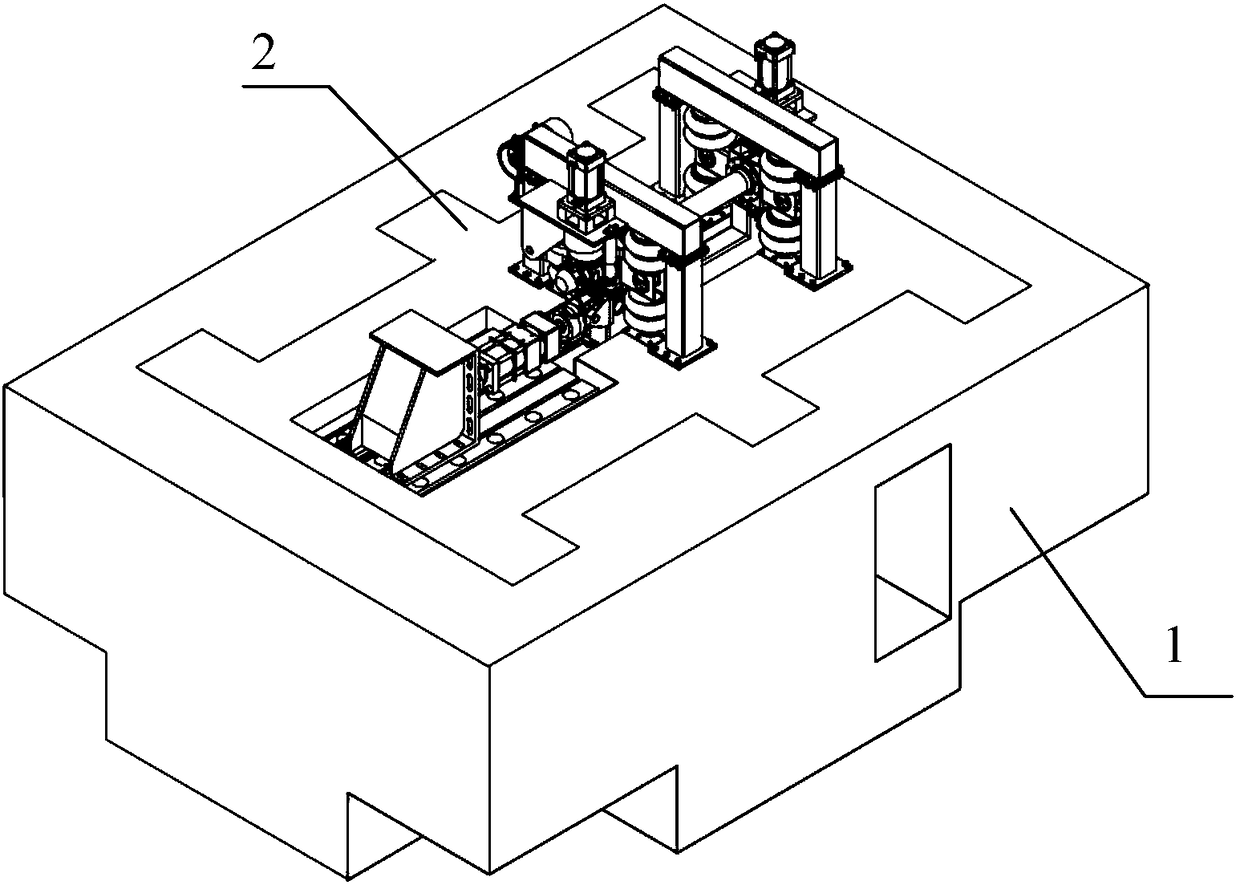

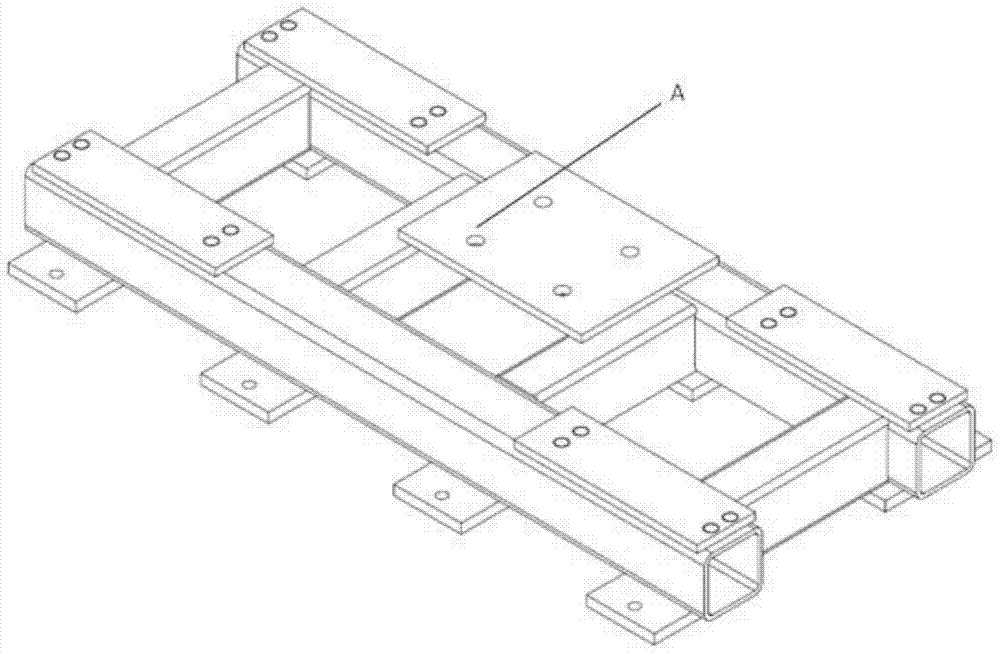

Axlebox bearing and grounding device comprehensive performance test bench

ActiveCN107328569BSolve the test infeasibility problemImprove safe operationMachine bearings testingThrust bearingBench test

The invention relates to an axle box bearing and earthing device comprehensive performance test-bed comprising a base foundation and a machinery device arranged in the base foundation; the machinery device mainly comprises an equipment mounting platform, a transverse counterforce bearer, a transverse actuator, a tested bearing and exciting beam device, no.1 and no.2 support gantry frameworks, no.1 and no.2 framework simulators, a power motor, and no.1 and no.2 vertical exciting actuators; the test-bed can simulate the speed and vibration conditions of the rail vehicle axle box bearing and shaft end earthing device running on a real line, can provide truly and reliable testing environments for the rail vehicle axle box bearing and shaft end earthing device bench tests, thus solving the problems that the rail vehicle cannot carry out motor unit axle box bearing reliability test in real operation and the shaft end earthing device life examination test. The test-bed is simple in structure, and can perform the axle box bearing and earthing device comprehensive performance test.

Owner:JILIN UNIV

High-speed wheel-rail relationship reliability test bench

The present invention relates to a high-speed wheel-rail relation reliability test bed. The high-speed wheel-rail relation reliability test bed comprises a rail wheel motion device and a power truck simulation loading framework, wherein two unilateral shafts of the rail wheel are respectively connected with number 1 roller linkage transmission shaft assembly body and a number 3 roller linkage transmission shaft assembly body; the power truck simulation loading framework includes a counter-force square tube beam frame vibration excitation device, a bearing frame-type support assembly body, a number 1 counter-force base fixed device and a number 2 counter-force base fixed device; the counter-force square tube beam frame vibration excitation device, the number 1 counter-force base fixed device and the number 2 counter-force base fixed device are respectively fixedly connected with globe joint bearing block assembly bodies of the numbers 1-3, the loading framework side beams of the side beam clamping plate assembly bodies of the numbers 1-2; and the outer sides of a number 5 spherical guide strip and a number 6 spherical guide strip are fixedly connected at the inner side of the number 1 bearding frame-type support. According to the invention, the problem is solved that a train is difficult to perform the wheel rail relation reliability test in the process of actual operation in the prior art, and the requirement of the reliability parameter detection of a rail vehicle wheel in a plurality of operation conditions is satisfied.

Owner:JILIN UNIV

Six-degree-of-freedom dynamic simulation loading test bench for drive train axle box bearings of EMUs

InactiveCN103323246BSolving the Infeasibility Problem of Reliability TestGood test foundationMachine bearings testingDrive shaftDegrees of freedom

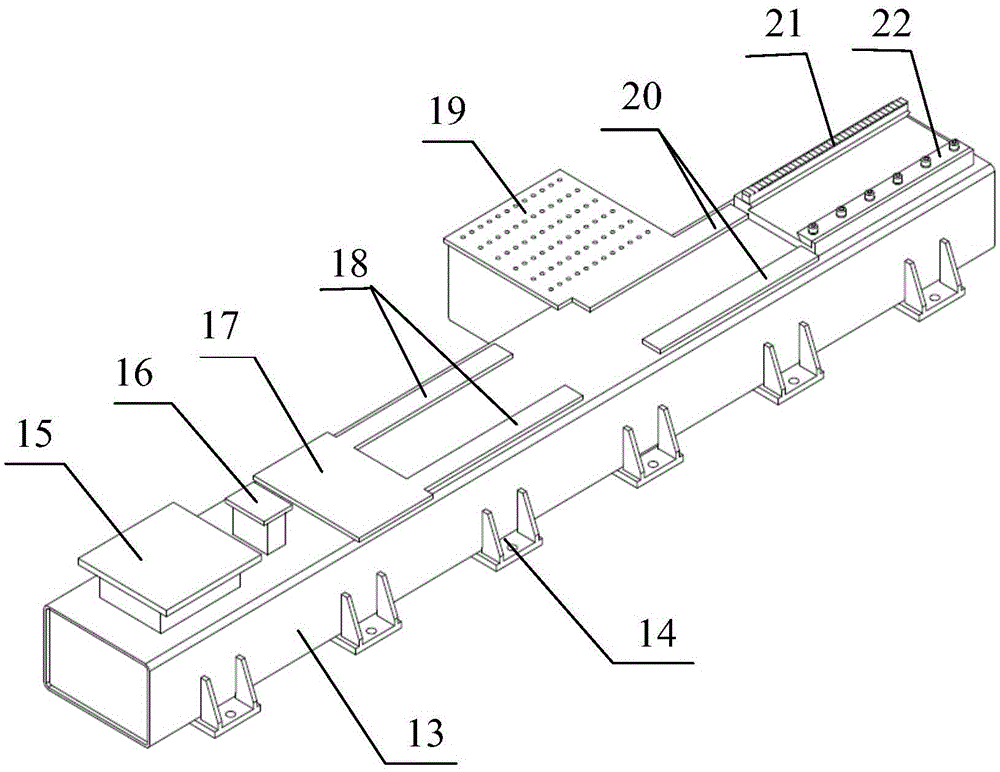

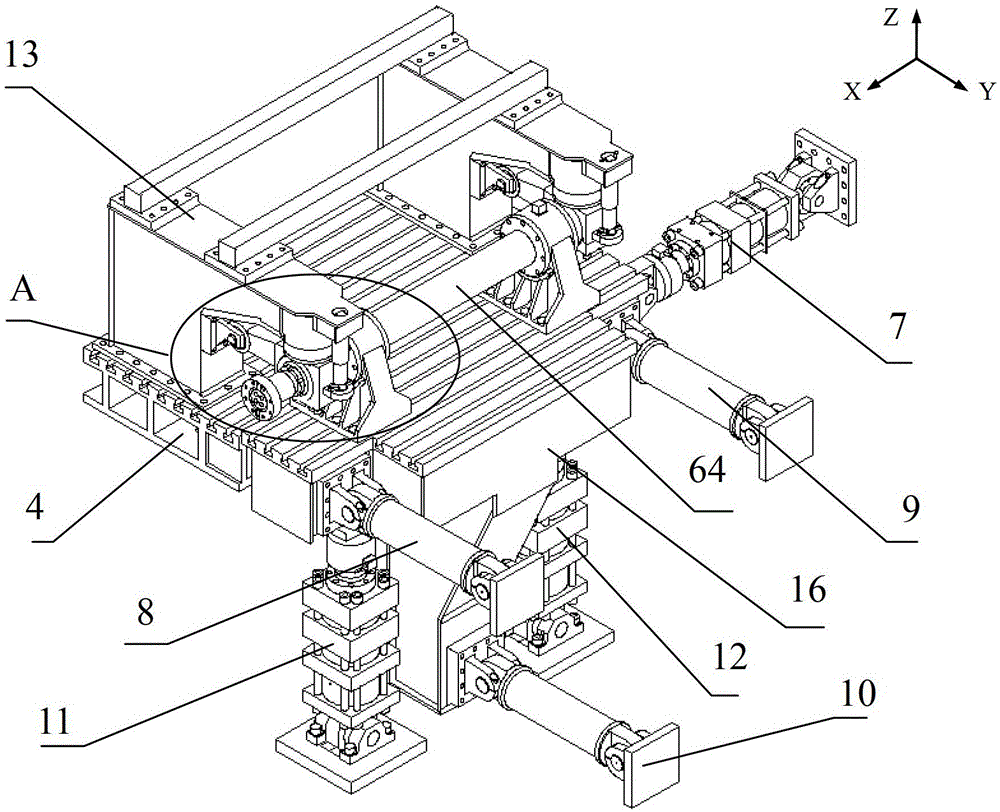

The invention discloses an electric multiple unit transmission system axle box bearing six-degree-of-freedom dynamic simulation load test platform and aims to overcome a problem that an electric multiple unit transmission system axle box bearing reliability test can be not carried out in a practical operation. The test platform comprises a power transmission torque detection testing device, a T type beam assembly body and a test piece assembly body. The T type beam assembly body is installed in the middle of a ground base. The power transmission torque detection testing device is installed at the left side of the T type beam assembly body, and the power transmission torque detection testing device is connected with the T type beam assembly body through a cross shaft type universal shaft coupler. The test piece assembly body is installed at the ground base above the T type beam assembly body. A simulated frame side beam supporting platform in the test piece assembly body and an upper surface of a rectangle bearing platform in the power transmission torque detection testing device are on the same horizontal plane, the simulated frame side beam supporting platform in the test piece assembly body is lower than an upper surface of a vibration T type beam for 50 mm, and the upper end of the vibration T type beam is parallel with the simulated frame side beam supporting platform.

Owner:JILIN UNIV

High-speed EMU axle box bearing three-degree-of-freedom dynamic loading reliability test bench

InactiveCN103323247BSimulate Vibration SituationsGood test foundationMachine bearings testingThree degrees of freedomDependability

The invention discloses a high-speed electric multiple unit axle box bearing three-degree-of-freedom dynamic load reliability test platform and aims to overcome a problem that an axle box bearing reliability test can be not carried out in a practical operation. The test platform comprises a torque detection testing device and an axle box bearing reliability test device. The torque detection testing device is connected with the axle box bearing reliability test device through a cross shaft type universal shaft coupler. The axle box bearing reliability test device comprises a simulated frame side beam test device, a three-degree-of-freedom vibration simulation test device and a shaft assembly for an axle box bearing test. The three-degree-of-freedom vibration simulation test device comprises a vibration T type beam and a lateral actuator. The shaft assembly for the axle box bearing test is fixed on the vibration T type beam through bolts. The simulated frame side beam test device and the three-degree-of-freedom vibration simulation test device are placed in a parallel way. The parallel distance of the vibration T type beam in the three-degree-of-freedom vibration simulation test device and a simulated frame side beam supporting platform in the simulated frame side beam test device is 20 mm to 40 mm.

Owner:JILIN UNIV

Membrane-based cell-derived xenograft (M-CDX) tumor model-based tissue slice making method

PendingCN109100200AEasy to storeReduce alcohol dehydration timePreparing sample for investigationWilms' tumorUrine

The invention relates to a tissue slice making method, in particular to a membrane-based cell-derived xenograft (M-CDX) tumor model-based tissue slice making method. The M-CDX tumor model-based tissueslice making method comprises the steps of incubating an embryonated egg in an incubator with temperature being 36-38 DEG C and humidity being 60-80% for 5-7 days, and cutting a window being 1 centimeter by 1 centimeter in a top end of the embryonated egg; and doping tumor cells in quantity being (0.5-8)*10<6> to an extracellular matrix to prepare a cell suspension liquid, dropwise adding the cell suspension liquid to a silica gel ring placed at a chorioallantoic membrane in advance, incubating the cells for 3 days at 37 DEG C and humidity being 60%, cutting tissue and the chorioallantoic membrane around the tissue by operating scissors, performing paraffin embedment and slicing, and performing HE dying and microscopic examination. The slice tissue prepared by the method comprises a complete cell structure type, each layer of tissue and cell position are relatively fixed, the morphological position relation of each layer of tissue and the cells is conveniently observed, the tissue iseasy to store, the M-CDX tumor model-based tissue slice making method is suitable for rapid and mass preparation of tissue slice, and a good test foundation is provided for researching effects of immunology and oncology during the formation process.

Owner:广州星燎生物科技有限公司

A device for testing the stress and strain of plastic concrete/mortar and its application method

ActiveCN104280290BExcellent R&D performanceGood test foundationUsing optical meansApparatus for force/torque/work measurementLaser targetData acquisition

The invention relates to a device for testing stress-strain of plastic concrete / mortar. The device comprises a forcemeter a, a forcemeter b, a laser displacement sensor c, a laser displacement sensor d, a force transmission unit, a laser target unit, a data acquirer and a die, wherein the forcemeter a and the forcemeter b are respectively arranged on the left side and the right side of the die; the laser target unit and the force transmission unit are arranged in an inner cavity of the die; the laser displacement sensor c and the laser displacement sensor d are respectively arranged at the left end and the right end of the top of the die; the data acquirer is connected with the laser displacement sensor c and the laser displacement sensor d respectively through circuits. Compared with the prior art, the device disclosed by the invention is simple in structure, convenient to operate and high in test precision, can automatically and continuously test the stress and the strain in the concrete / mortar in any stage from the moment of pouring, and the practicability is high.

Owner:TONGJI UNIV

Electric open-loop suspended transmission system reliability test bench

InactiveCN105043757BReduce volumeSmall footprintMachine gearing/transmission testingElectric power transmissionEngineering

The invention discloses an electric open-loop hanging transmission system reliability test bench. In order to overcome the problem that the EMU transmission system reliability test cannot be performed during the actual operation of the EMU, it includes a transmission system vertical vibration device, Transverse vibration excitation device for transmission system, suspension support device, gearbox power open-loop suspension vibration excitation assembly, torque detection test device and installation platform. The vertical vibration excitation device of the transmission system is located on the right side of the installation platform; the suspension support device is installed on the vertical vibration excitation device of the transmission system. On the hanging basket in the hanging support device, two U-shaped seats are installed on the left and right sides of the simulated high-speed train transmission system assembly, and the drive motor and drive train transverse vibration device are located on the left side of the installation platform. The dynamometer is installed on the foundation; the torque detection test device is installed on the installation platforms at the front and rear sides of the simulated high-speed train transmission system assembly.

Owner:JILIN UNIV

EMU axle end grounding device wear test bench

InactiveCN105403418BSolving the Infeasibility of Loss TestingGuaranteed accuracyRailway vehicle testingPower flowElectric machinery

Owner:JILIN UNIV

High-speed EMU dual-body six-dimensional vibration transmission train assembly reliability test bench

InactiveCN103630358BTruly reflect the status of fatigue damageGood test foundationMachine gearing/transmission testingRailway vehicle testingShaped beamThree degrees of freedom

The invention discloses a reliability test bench of a two-body six-dimensional vibration drive train assembly for a high-speed motor train unit, and solves the problem that a drive train is put into a static environment to respectively research a reducer or a drive motor in the prior art. The reliability test bench comprises a three-degree-of-freedom vibration table of a vibration shaft assembly and a three-degree-of-freedom vibration table of a traction motor assembly, wherein the three-degree-of-freedom vibration table of the vibration shaft assembly and the three-degree-of-freedom vibration table of the traction motor assembly are arranged on a foundation back to back in parallel; the three-degree-of-freedom vibration table of the traction motor assembly comprises a second three-degree-of-freedom vibrating simulation test device, a traction motor, a fixing clamp assembly body and a drive train gear box fixed bracket assembly body; the second three-degree-of-freedom vibrating simulation test device comprises a second vibrating T-shaped beam, a second transverse actuator, a third vertical actuator and a fourth vertical actuator; the traction motor, the fixing clamp assembly body and the drive train gear box fixed bracket assembly body are fixedly connected to the upper surface of the second vibrating T-shaped beam.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com