High-speed train transmission system assembly reliability test bed

A technology of high-speed EMUs and drive trains, applied in the direction of machine gear/transmission mechanism testing, vibration testing, transmission device parts, etc., to achieve good social and economic benefits, ensure accuracy and correctness, and achieve reasonable structural design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

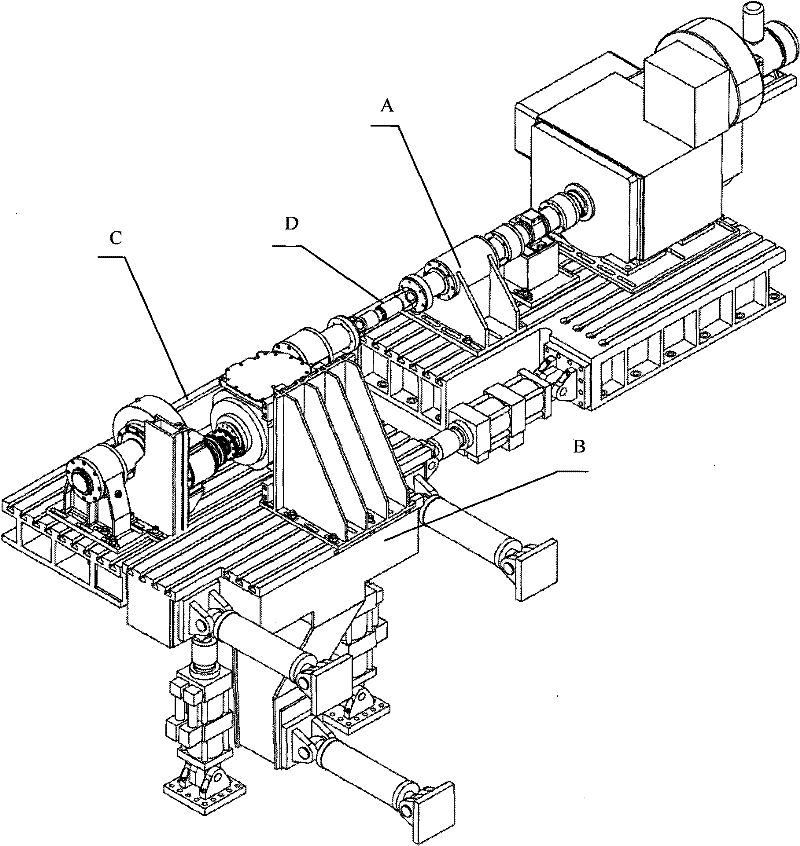

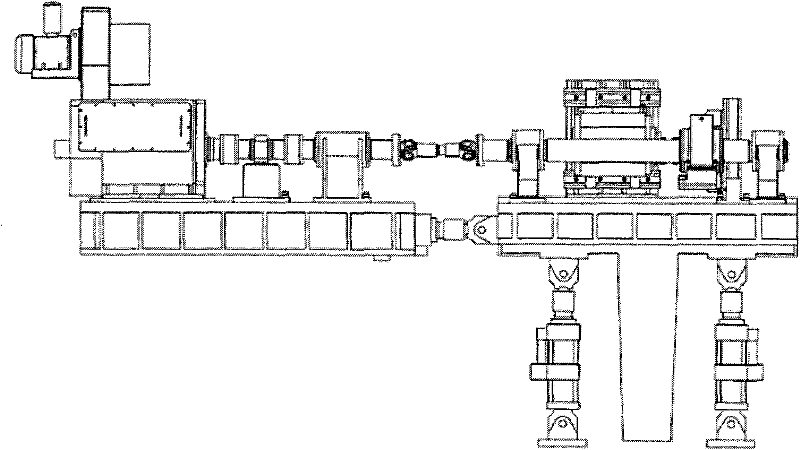

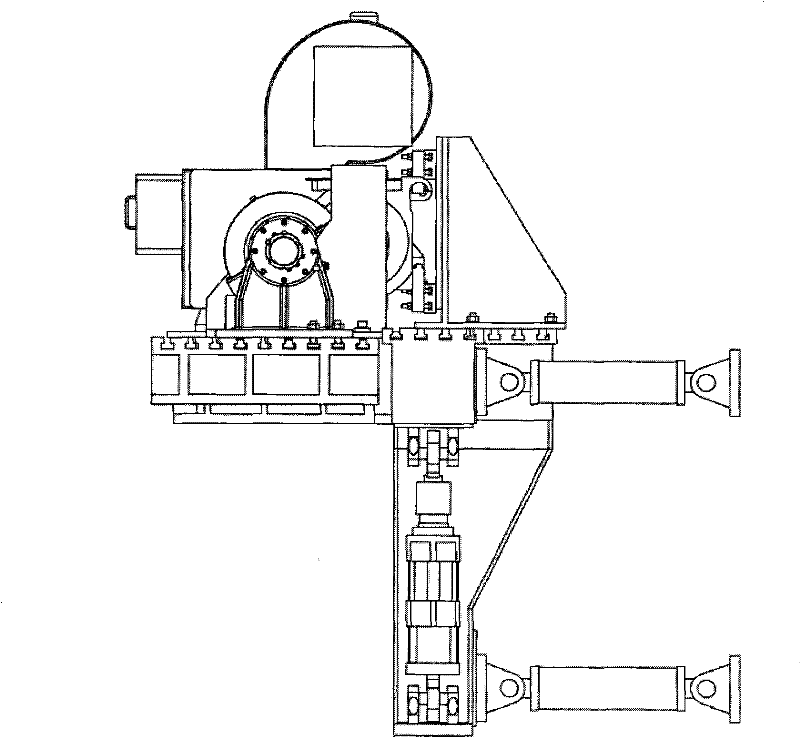

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

[0035] The purpose of the present invention is to provide a high-speed EMU drive train assembly reliability test bench to meet the needs of reliability parameter detection of rail vehicle drive systems under various operating conditions. The test bench adopts a reasonable structural design of the load simulation system, which can simulate the vibration conditions of three degrees of freedom and three degrees of freedom coupling, that is, accurately simulate the vibration state of rail vehicles running on the road, thus ensuring the transmission of high-speed EMUs. The correctness and authenticity of the test results of the system reliability parameters. All the tests are destructive tests, so that the reasons for the destruction of the tested drive train and the specific technical parameters can be accurately given. Researching the reliability of high-speed EMU drive train ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com