Reliability test bench of two-body six-dimensional vibration drive train assembly for high-speed motor train unit

A technology for high-speed EMUs and drive trains, used in machine gear/transmission testing, railway vehicle testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

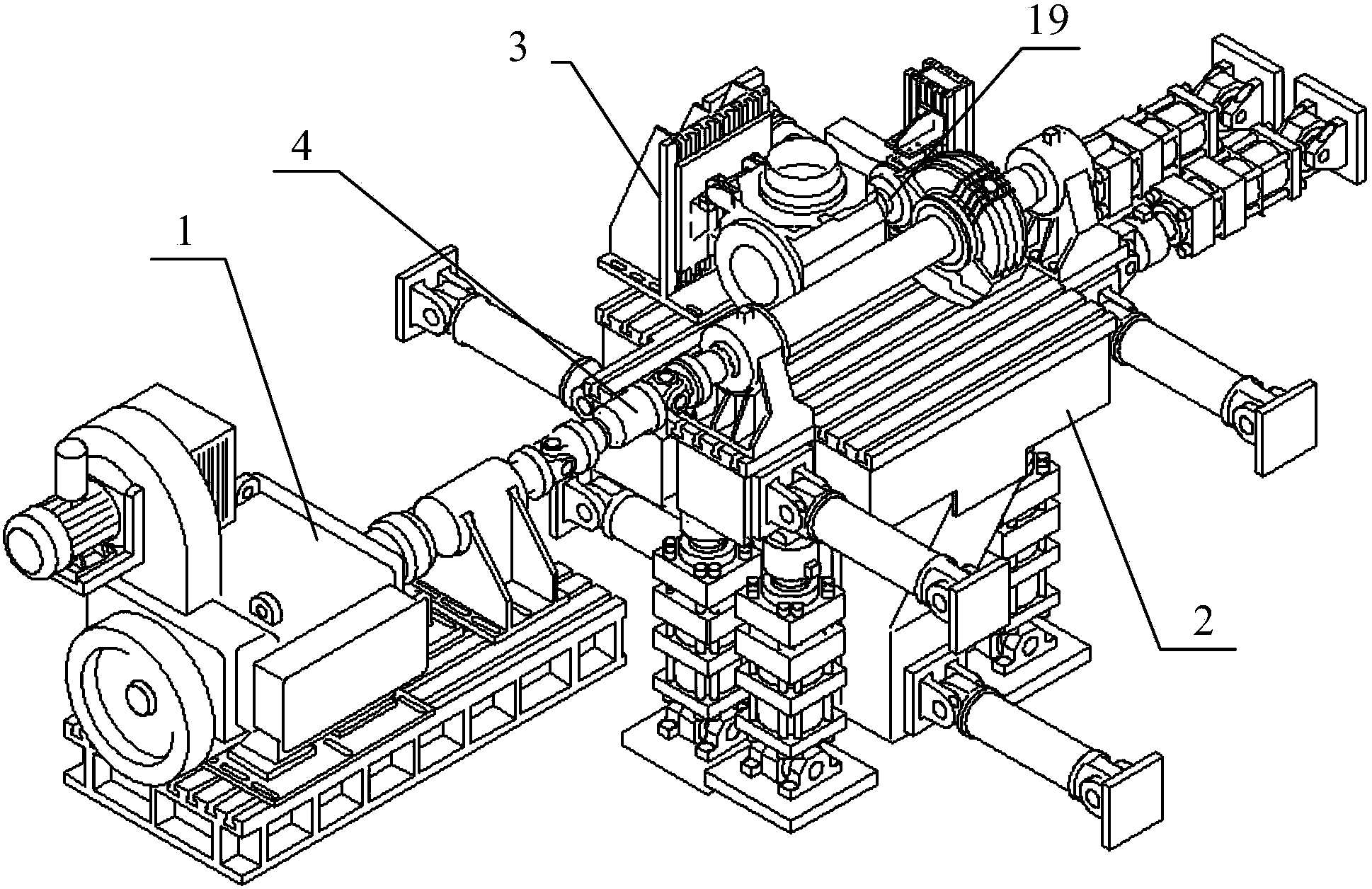

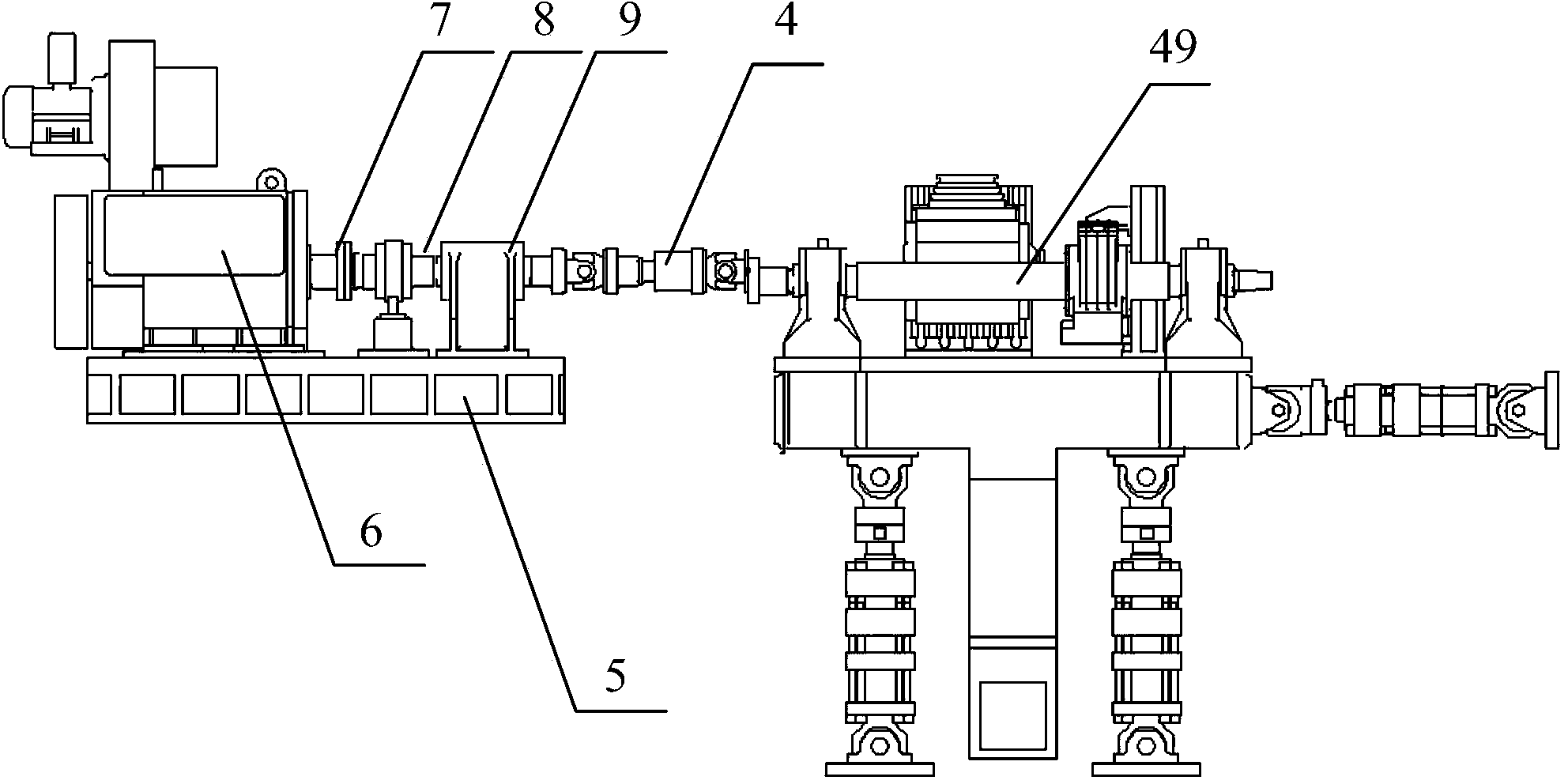

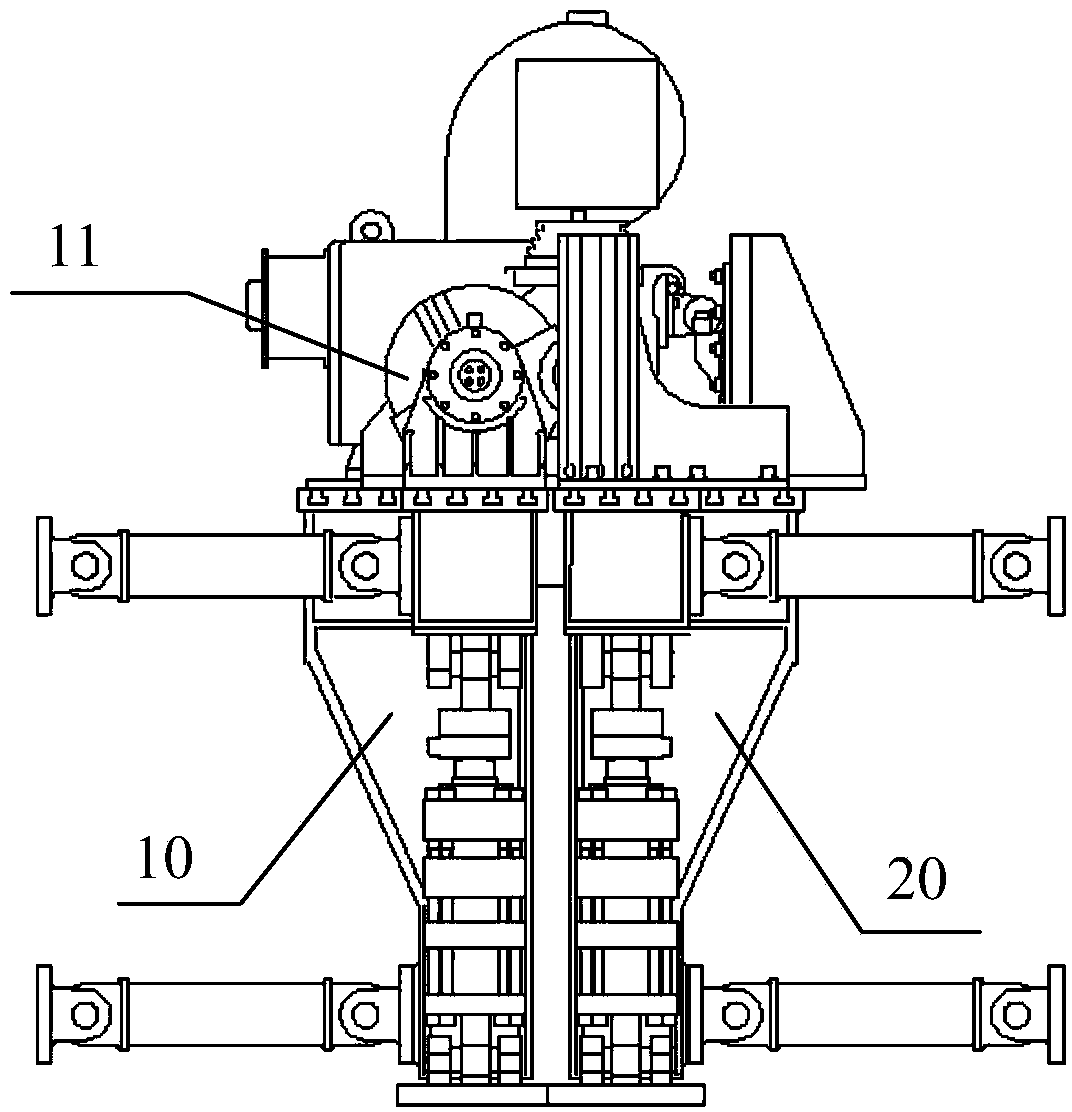

[0051] The present invention is described in detail below in conjunction with accompanying drawing:

[0052] The invention provides a reliability test bench for a two-body six-dimensional vibration drive train assembly of a high-speed EMU to meet the requirements for detecting reliability parameters of a rail vehicle drive train assembly under various operating conditions. The test bench adopts the structural design of a reasonable load simulation system, which avoids the danger and loss caused by the destructive test on the actual running vehicle. Two sets of three-degree-of-freedom vibration simulation test The external excitation is applied to the gear box assembly to simulate the vibration of the high-speed EMU in the actual track, which provides a good test basis for the reliability test of the high-speed EMU drive train and ensures the accuracy and correctness of the test. The tests done are all destructive tests, so that the cause of the failure of the traction motor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com