Axlebox bearing and grounding device comprehensive performance test bench

A technology of comprehensive performance and grounding device, which is applied in the field of rail vehicle axle box bearing and grounding device test device, can solve the problem that cannot be tested in the reliability test of EMU axle box bearing, achieve a good test foundation, improve safe operation, and ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the drawings:

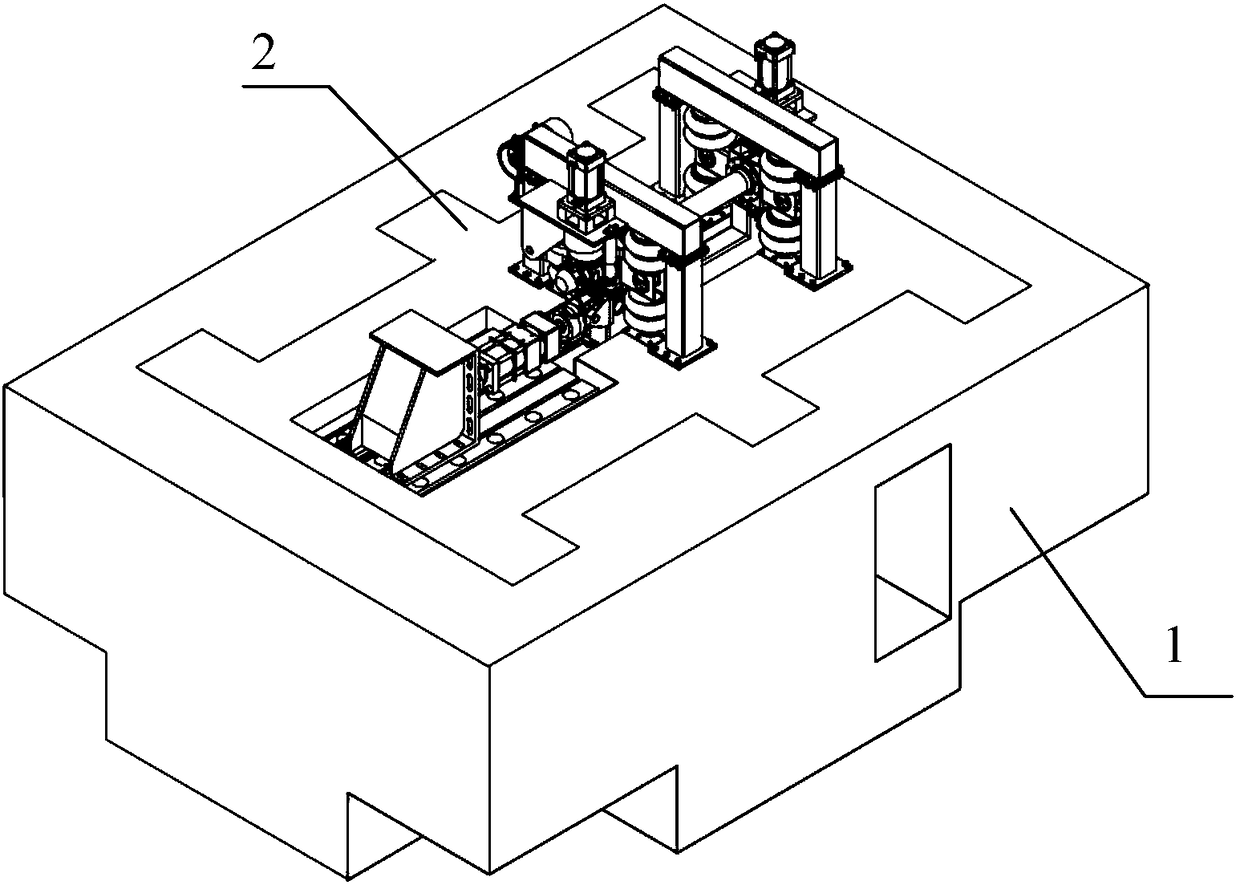

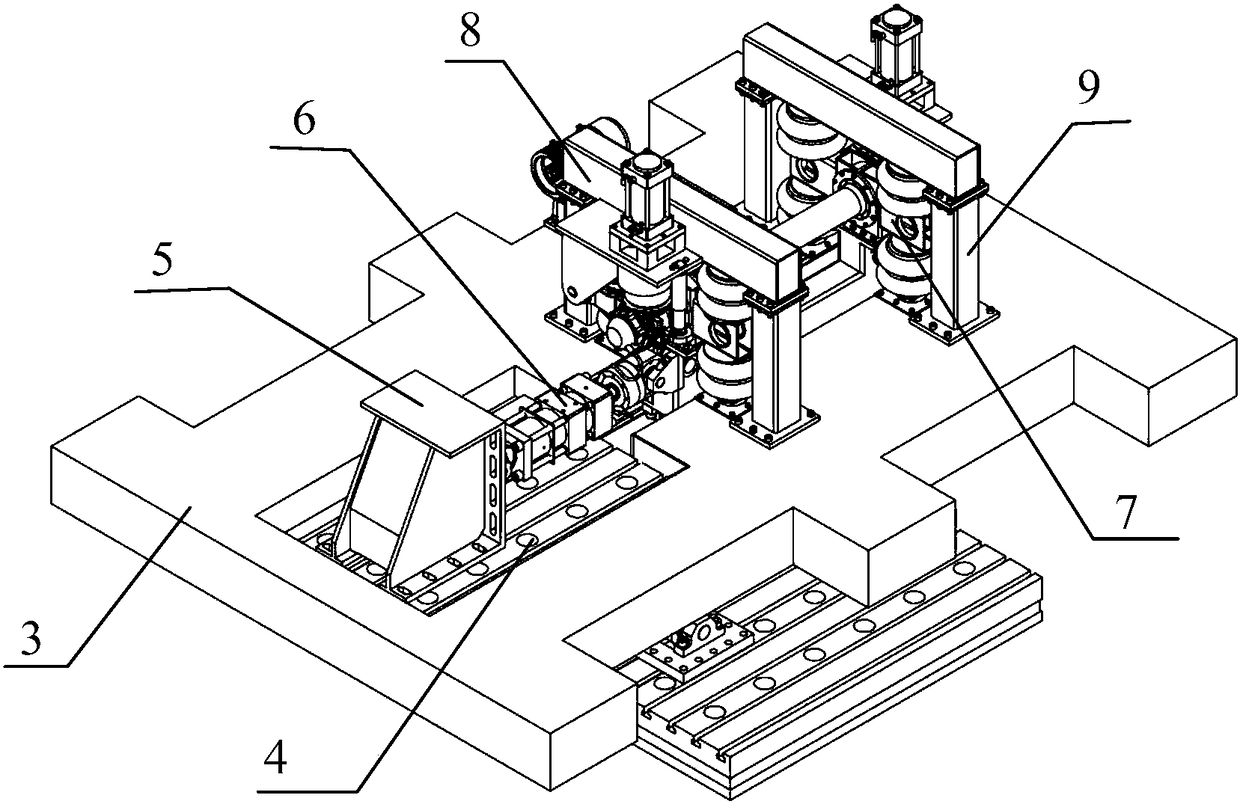

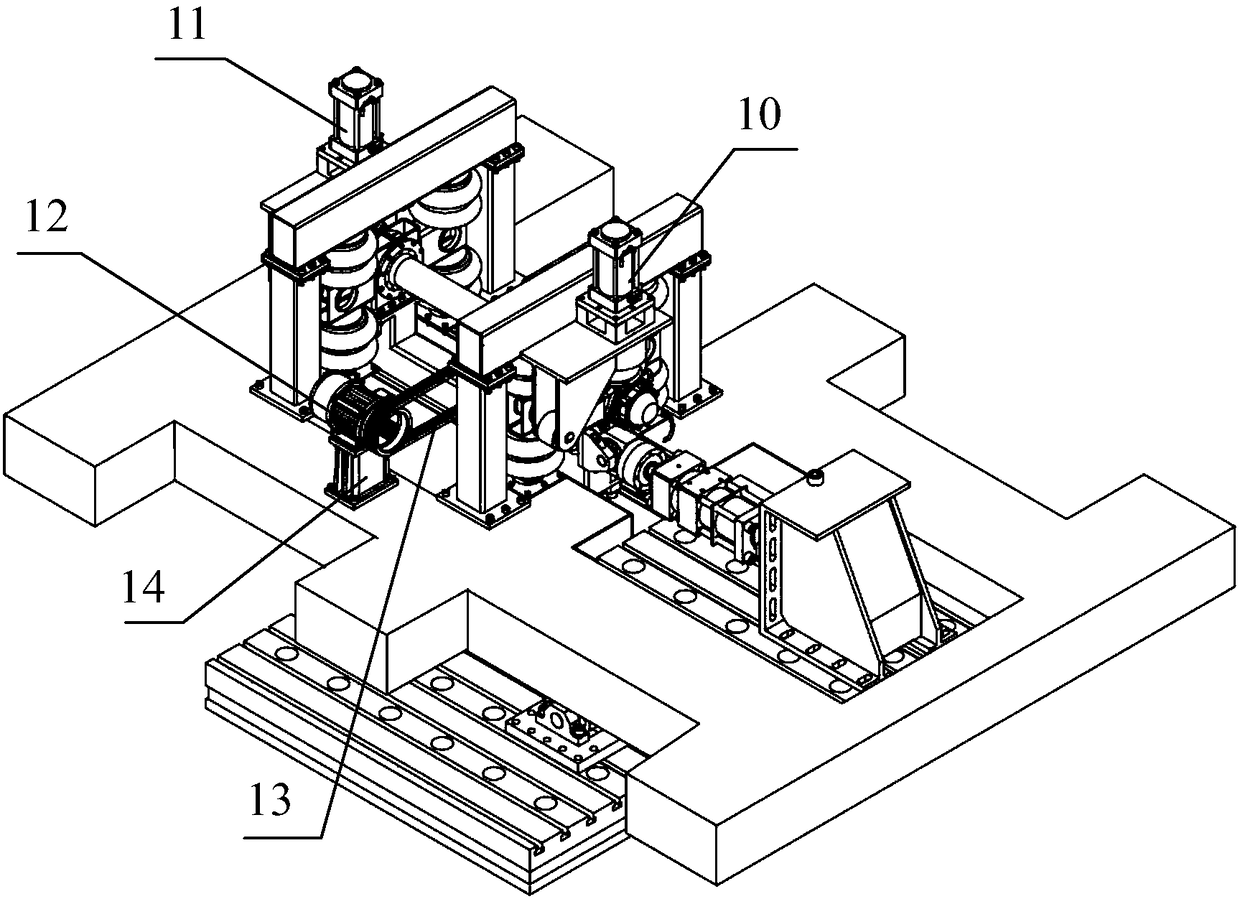

[0038] Refer to Figure 1 to Figure 4 The comprehensive performance test bench for axlebox bearings and grounding devices includes a foundation foundation 1 and a mechanical device 2. The mechanical device 2 is installed in the foundation foundation 1, and the mechanical device 2 is installed by the equipment installation platform 3 and the lateral reaction support. Platform 4, Transverse reaction support 5, Transverse actuator 6, Test bearing and excitation beam device 7, No. 1 supporting gantry frame 8, No. 2 supporting gantry frame 9, No. 1 frame simulation device 10, No. 2 frame simulation The device 11, the power motor 12, the transmission belt 13, the motor support 14, the vertical actuator installation platform 15, the No. 1 vertical excitation actuator 16 and the No. 2 vertical excitation actuator 17 are composed.

[0039] The equipment installation platform 3 is made of cast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com