Air dehumidifier based on composite microporous membranes and dehumidifying equipment

A microporous membrane and dehumidifier technology, applied in the field of spacecraft environmental control, can solve the problems of multiple equipment and complex system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The composite microporous membrane dehumidification method and device of the present invention will be described in detail below with reference to the accompanying drawings, but the description is only exemplary and not intended to limit the protection scope of the present invention.

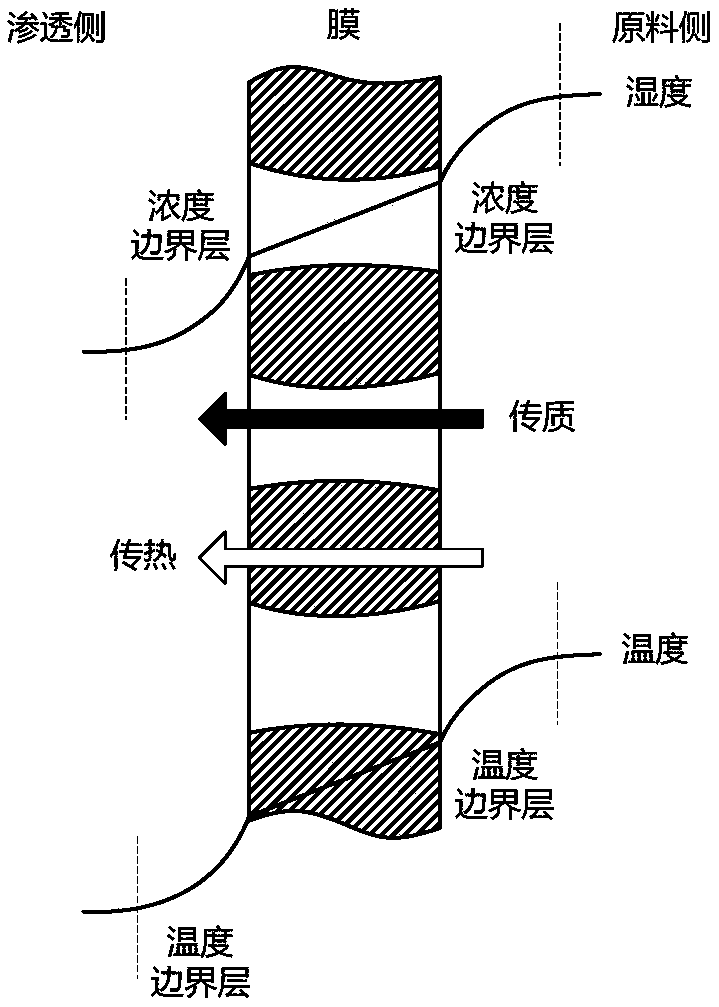

[0023] see figure 1 , figure 1 It shows a schematic diagram of water vapor passing through the hollow fiber membrane in the air dehumidification method of the composite microporous membrane of the present invention. The water vapor mass transfer process includes convective mass transfer on the wet air side, diffusion in the membrane, and convective mass transfer on the cold water side. Among them, the composite membrane separates the humid air from the low-temperature cold water, the low-temperature cold water flows through the permeation side of the composite membrane, the hot and humid air flows through the raw material side outside the membrane tube, and the water vapor condenses into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com