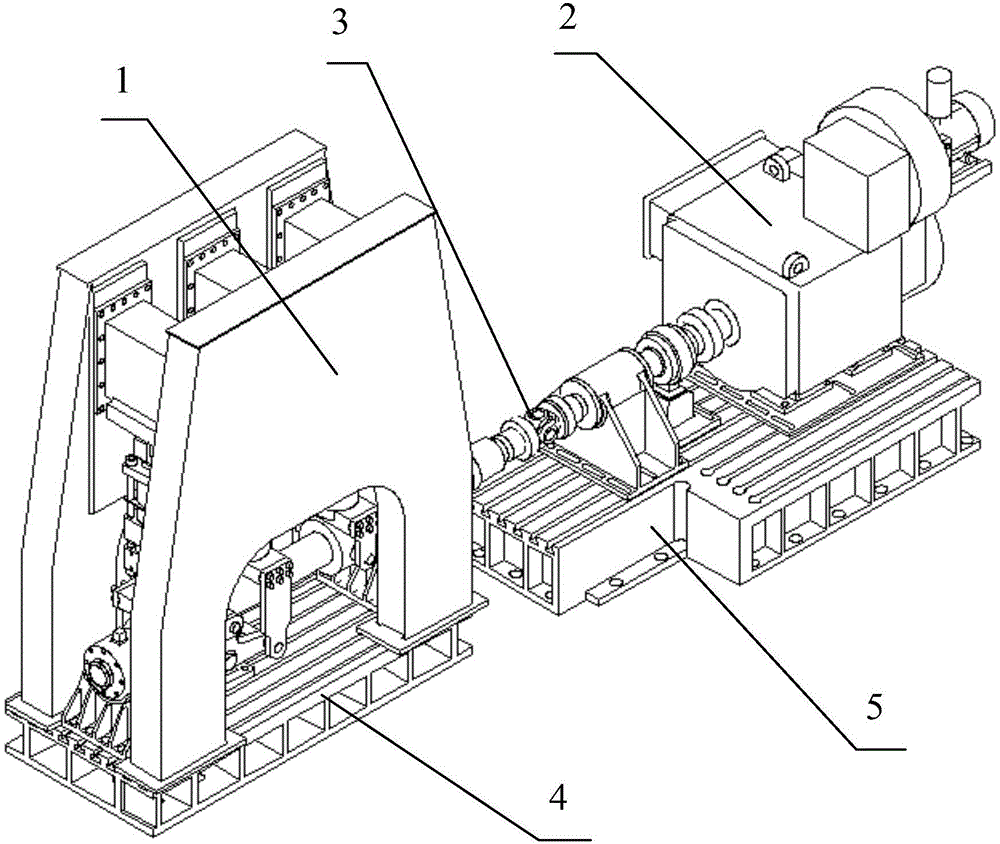

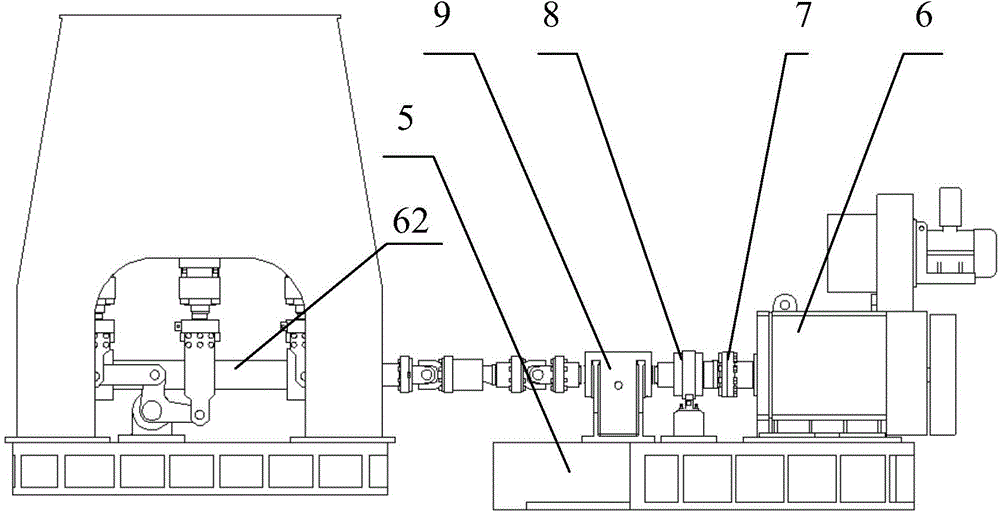

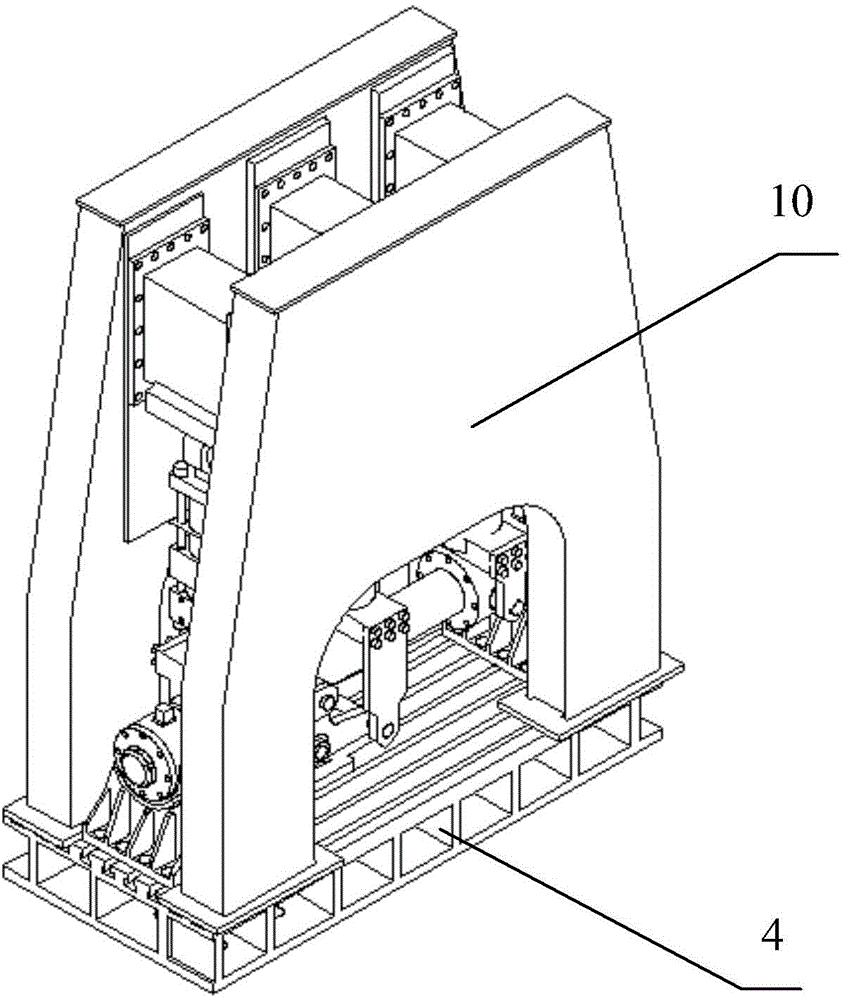

High-speed EMU axle box bearing gantry-type reaction frame two-dimensional excitation loading test bench

A technology for high-speed EMUs and axlebox bearings, which is applied in the field of rail vehicle drive train parameter detection and test platforms, and can solve problems such as failure of axlebox bearing reliability tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention is described in detail below in conjunction with accompanying drawing:

[0072] The purpose of the present invention is to provide a high-speed EMU axle box bearing gantry type reaction force frame two-dimensional excitation loading test bench, to solve the problem that it is difficult to carry out the reliability test of the axle box bearing in the actual operation of the existing train, so as to meet the requirements of the rail vehicle axle. The need for reliability parameter detection of box bearings under various operating conditions. The vertical and transverse excitation devices of the axle box bearing included in the test bench can accurately simulate the radial and axial loads on the axle box bearing in actual working conditions and the vibration of the high-speed EMU when it is running on the actual line. It truly reproduces the vibrations suffered by the drive train of rail vehicles during operation, thereby ensuring the correctness and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com