Motor train unit shaft end grounding apparatus wear test bench

A grounding device and wear test technology, applied in railway vehicle testing and other directions, can solve problems such as the wear test of ungrounded devices, achieve good social and economic benefits, ensure accuracy, and improve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the technical solutions of the present invention, the present invention is described in detail below in conjunction with the accompanying drawings:

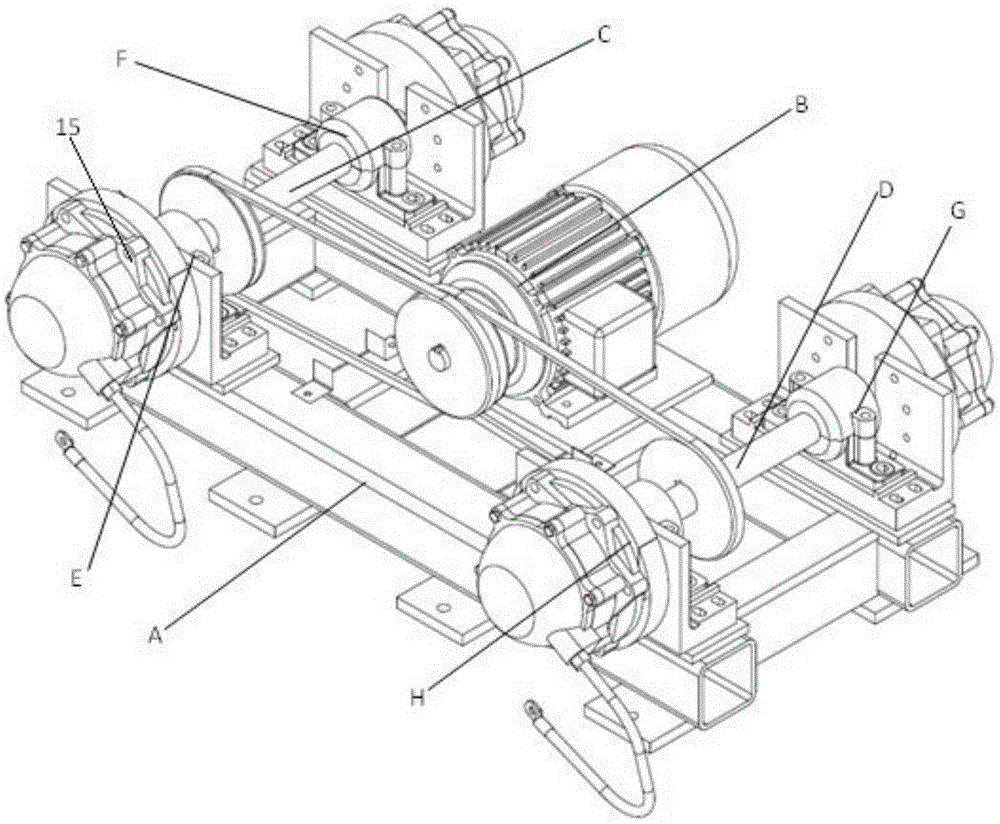

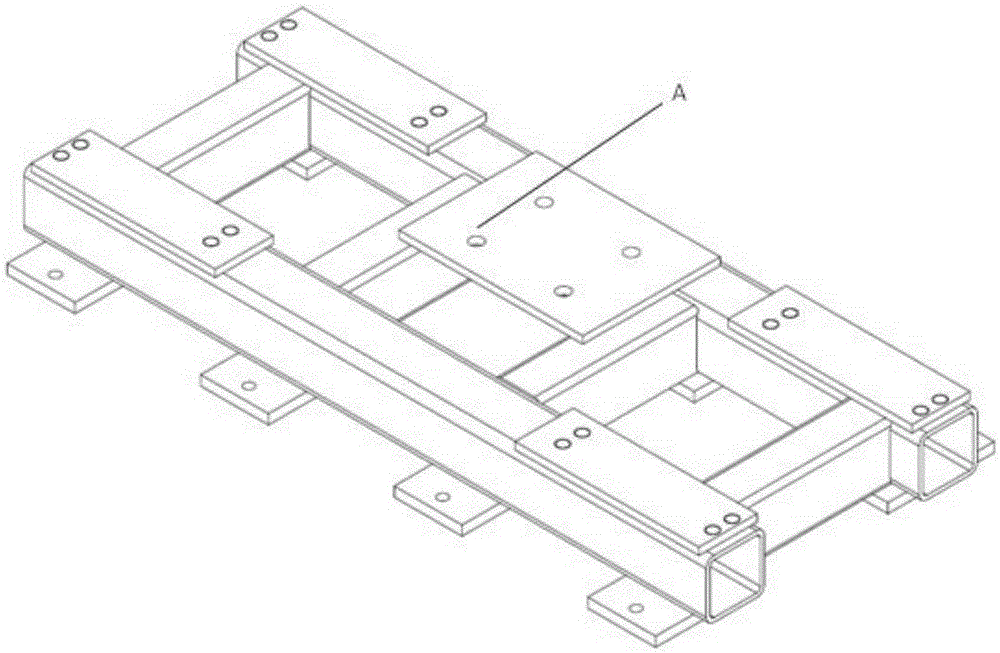

[0046] see figure 1 , EMU shaft end grounding device wear test bench includes basic frame A, drive motor assembly B, first test shaft assembly C, second test shaft assembly D, one shaft left mounting ring assembly E, one shaft right Side mounting ring assembly F, two-axis left mounting ring assembly G and two-axis right mounting ring assembly H.

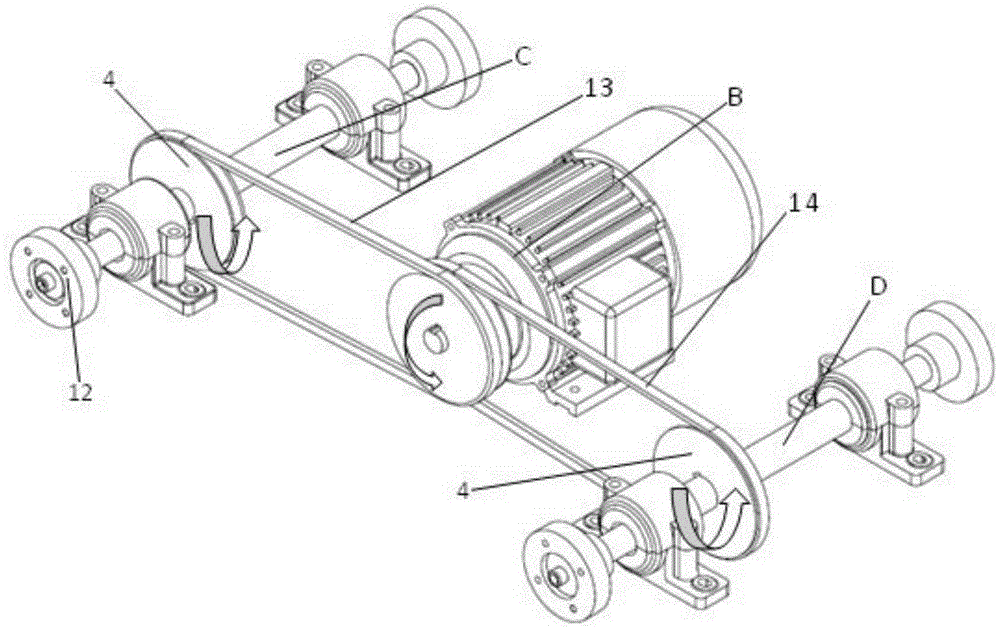

[0047] see figure 2 , The power train components in the EMU shaft end grounding device wear test bench include drive motor assembly B, first test shaft assembly C, one-shaft drive belt 13, second test shaft assembly D and two-shaft drive belt 14. When power is supplied to the motor, the motor normally operates to generate rotational torque; as shown by the arrow in the figure, the rotational torque shown by the arrow is generated. The power passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com