Stone polishing device with periodical ash removal function for building

A constructional and periodic technology, applied in grinding drives, grinding/polishing safety devices, grinding machines, etc., can solve problems such as reducing grinding efficiency, and achieve the effects of high processing efficiency, reduced effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

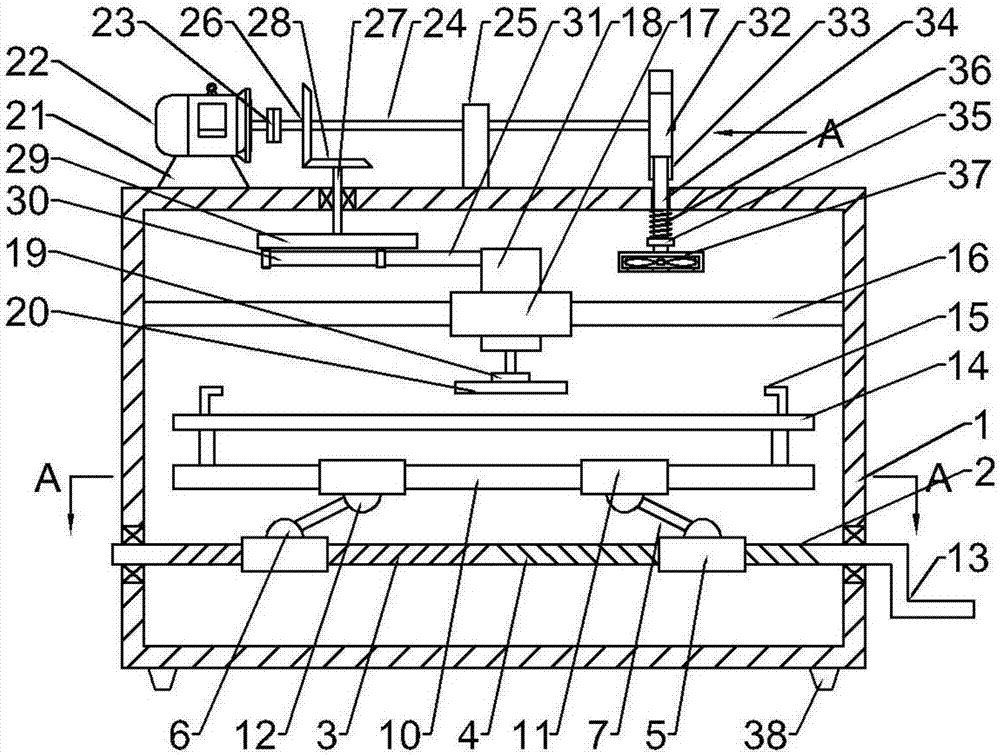

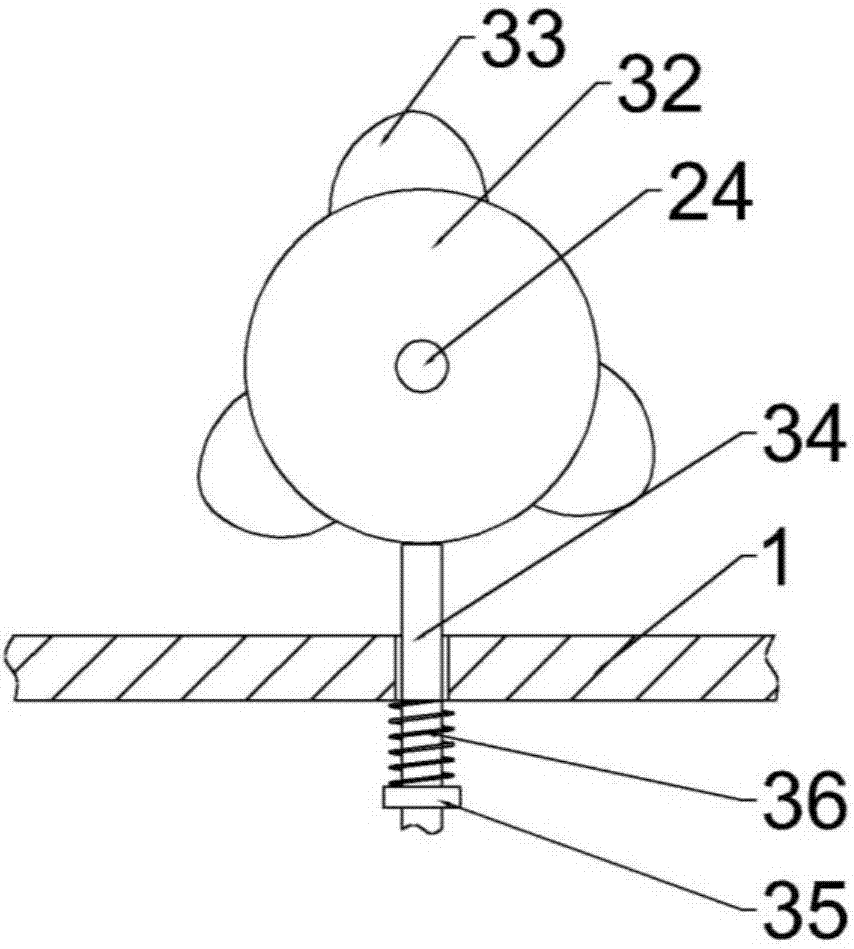

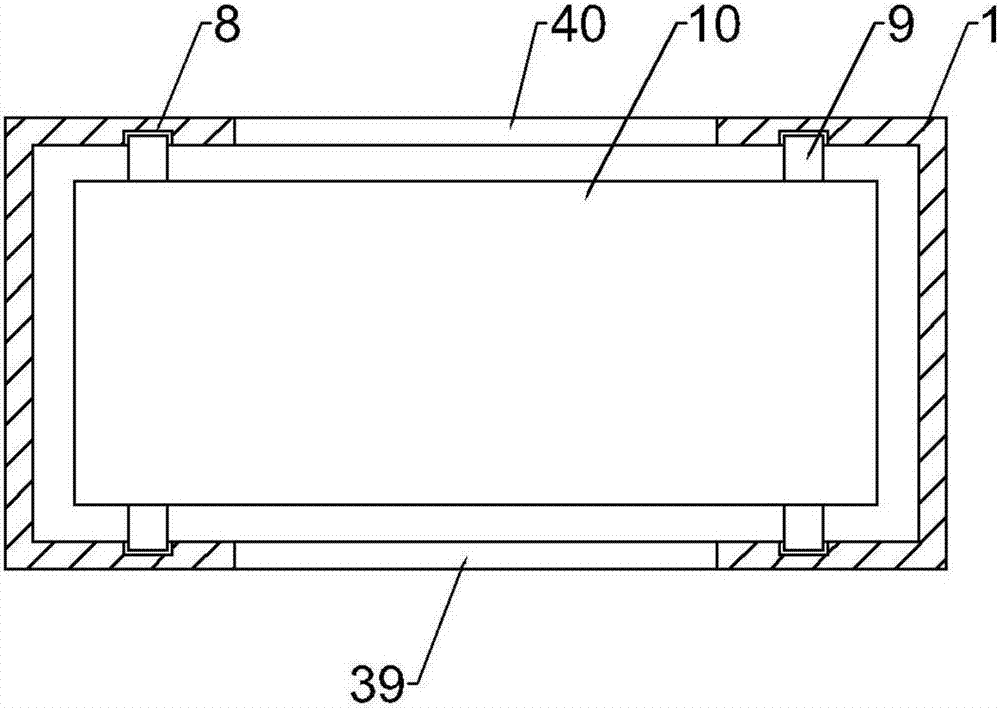

[0022] see Figure 1-3 , a stone grinding device for building with periodic dust removal function, comprising a frame 1, the bottom of the frame 1 is connected with an adjustment shaft 2 through bearing rotation, and the outer side of the left end of the adjustment shaft 2 is fixedly connected with a right thread 3, the The outer side of the right end of the adjustment shaft 2 is fixedly connected with a left thread 4, and the outside of the left thread 4 and the right thread 3 are all threaded with an adjustment sleeve 5, and the upper part of the adjustment sleeve 5 is fixedly connected with a lower rotating hinge 6, and the upper part of the lower rotating hinge 6 Both are fixedly connected with inclined connecting rods 7, and longitudinal chute 8 is arranged symmetrically on the left and right under the inner side wall of the frame 1, and a lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com