Miniaturized flexible micro clamp based on piezoelectric driving

A technology driven by piezoelectric ceramics and piezoelectric ceramics, applied in the direction of collets, micro manipulators, manipulators, etc., can solve problems such as optical fiber sliding, clamping failure, gas leakage of vacuum suction equipment, etc., to avoid gaps and large displacement output , Guarantee the effect of end grabbing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings.

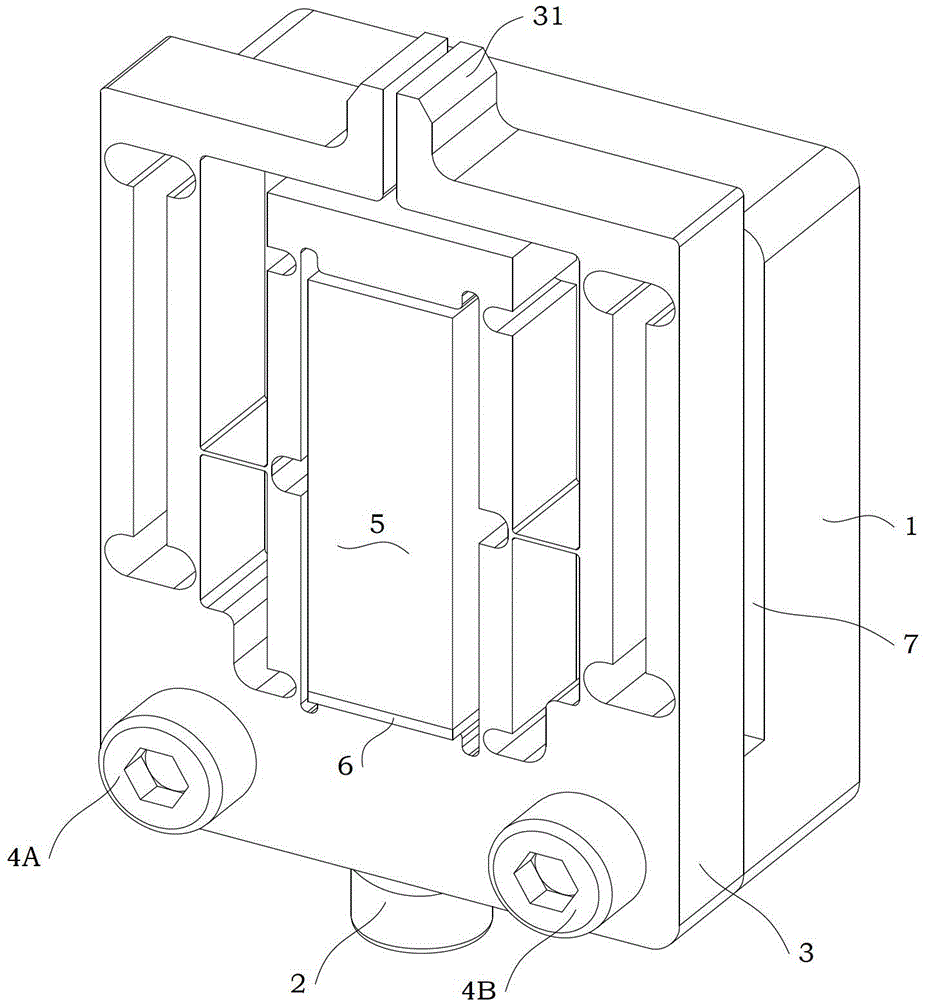

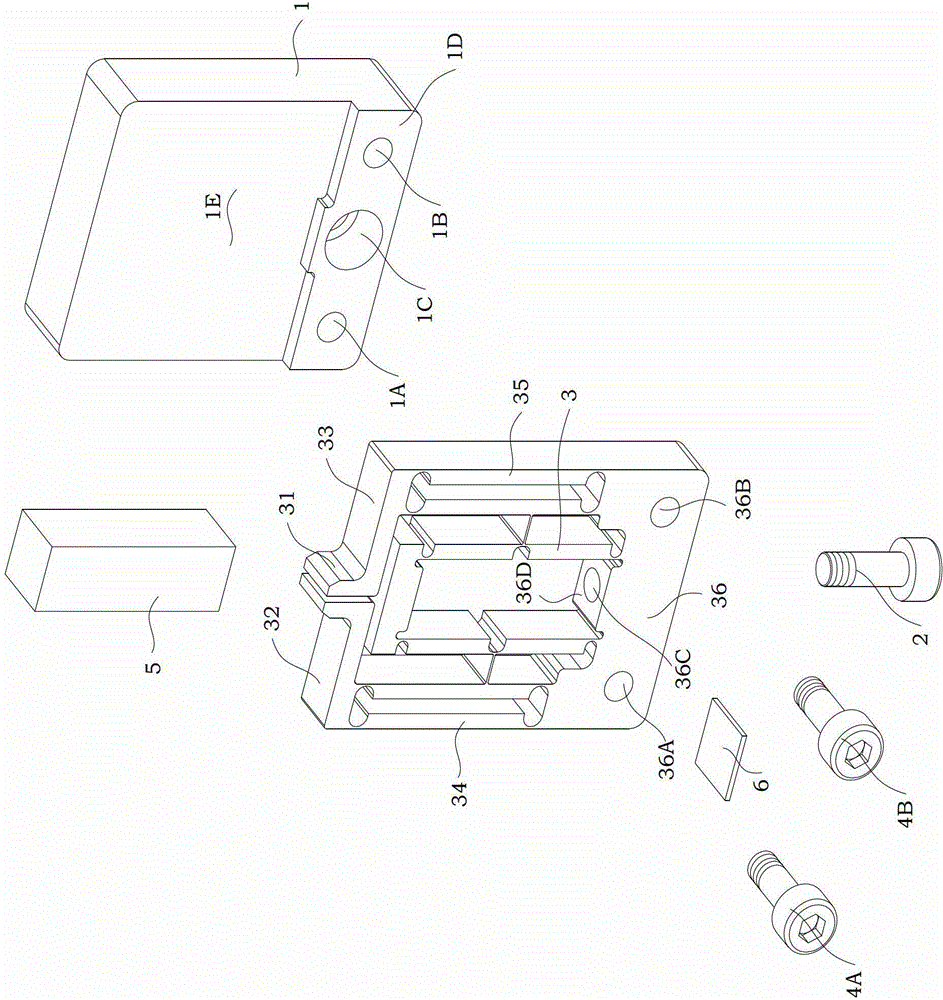

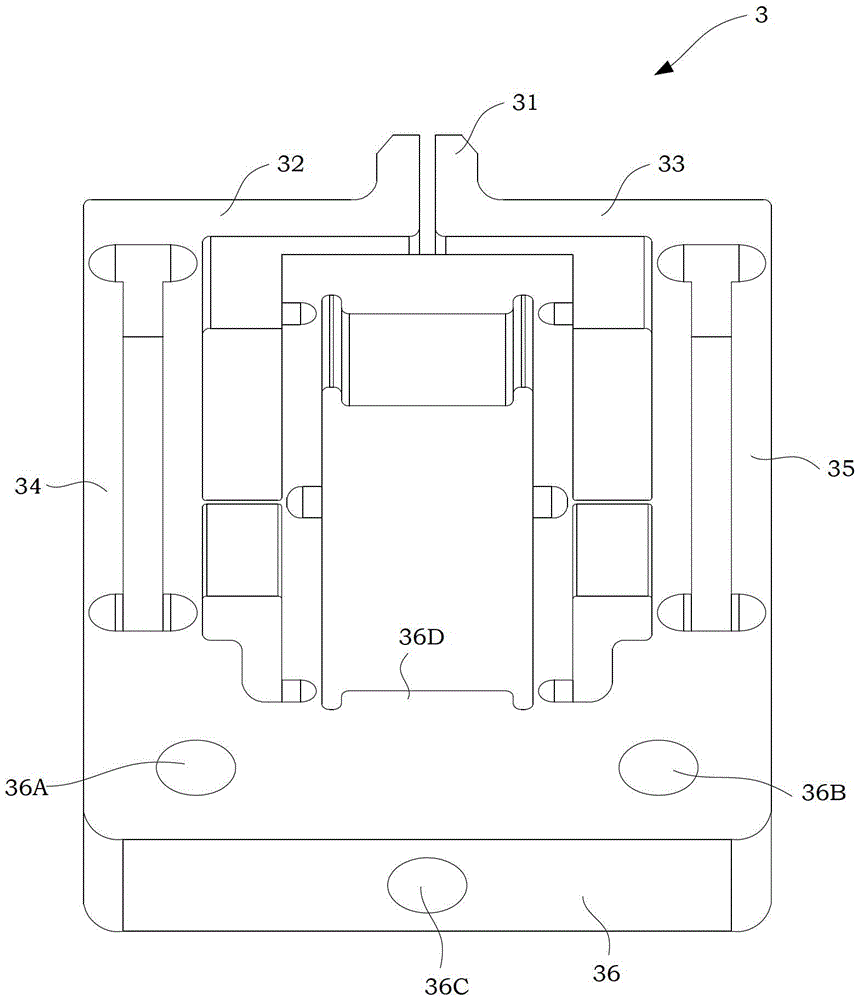

[0036] see figure 1 , Figure 1A As shown, the miniaturized flexible micro-clamp driven by piezoelectric ceramics of the present invention includes a base 1, a pre-tightening screw 2, a motion transmission mechanism 3, a first fixing screw 4A, and a second fixing screw 4B , a piezoelectric ceramic driver 5 and a gasket 6; the base 1 and the motion transmission mechanism 3 are fixedly installed through the first fixing screw 4A and the second fixing screw 4B, and the pre-tightening screw 2 is installed at the rear end of the motion transmission mechanism 3, and the piezoelectric The ceramic driver 5 and the washer 6 are installed in the first slit 351 of the motion transmission mechanism 3 .

[0037] The micro-gripper designed in the present invention can achieve parallel grasping of the closed micro-gripper through the two-stage amplification in the motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com