Drilling method improving PCB plate counter-drilling precision

A technology of PCB board and drilling method, which is applied in the field of drilling using thick PCB boards, and can solve problems affecting product performance, affecting hole position accuracy, and offsetting of two-sided holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0021] A drilling method for improving the drilling accuracy of PCB board 1, comprising the steps of:

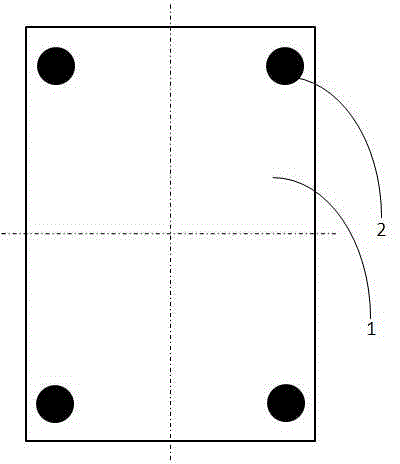

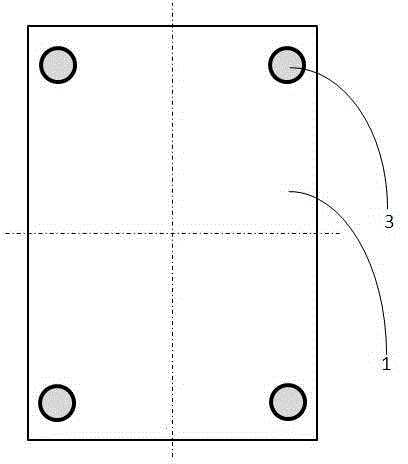

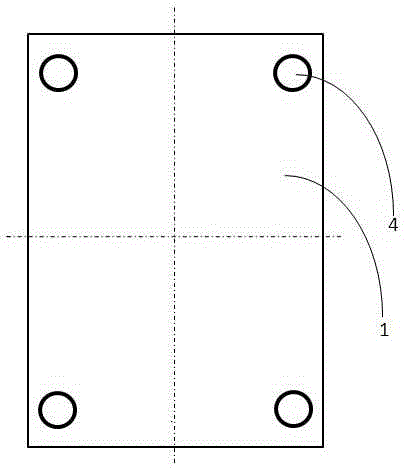

[0022] Step 1, the inner layer pads 2 are set on the four corners of the PCB board 1, and the PCB board 1 is pressed together; as a preference, the pads 2 are circular pads 2.

[0023] Step 2, use the punching equipment to grab the black ghost image of the inner layer pad 2, and use a drill to punch a pre-drilled hole from one side. The depth of the pre-drilled hole is less than the thickness of the PCB board 1; as a preferred method, the punching device is X- RAY, the depth of the pre-drilled holes is 55% to 60% of the thickness of the PCB board 1 . It should be noted that the diameter of the drill is smaller than the diameter of the pad 2; as a preference, the diameter of the drill is <0.7mm

[0024] Step 3, the PCB board 1 is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com