Waterborne polyurethane coating for coated aluminum sheets and preparation method of waterborne polyurethane coating

A water-based polyurethane, polyurethane acrylic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to meet the drilling accuracy, poor environmental adaptability, intolerant of preservation, etc., to increase the number of drilling stacks, The effect of good environmental resistance and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

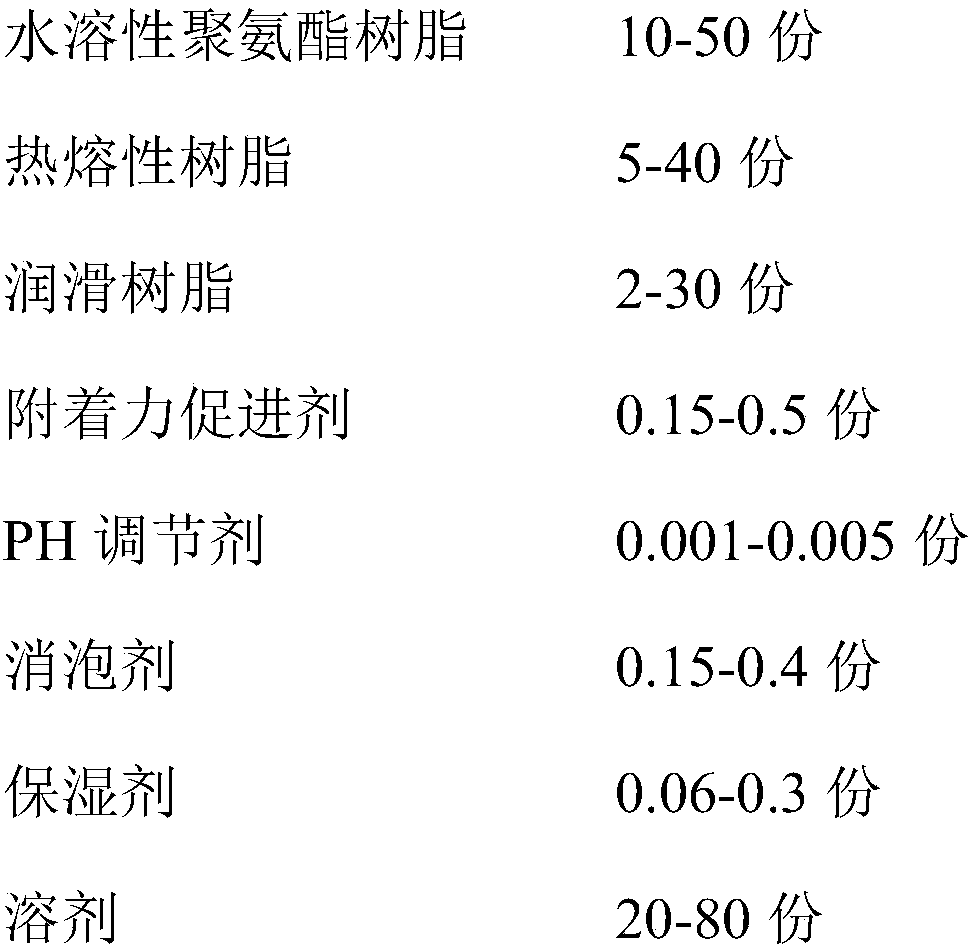

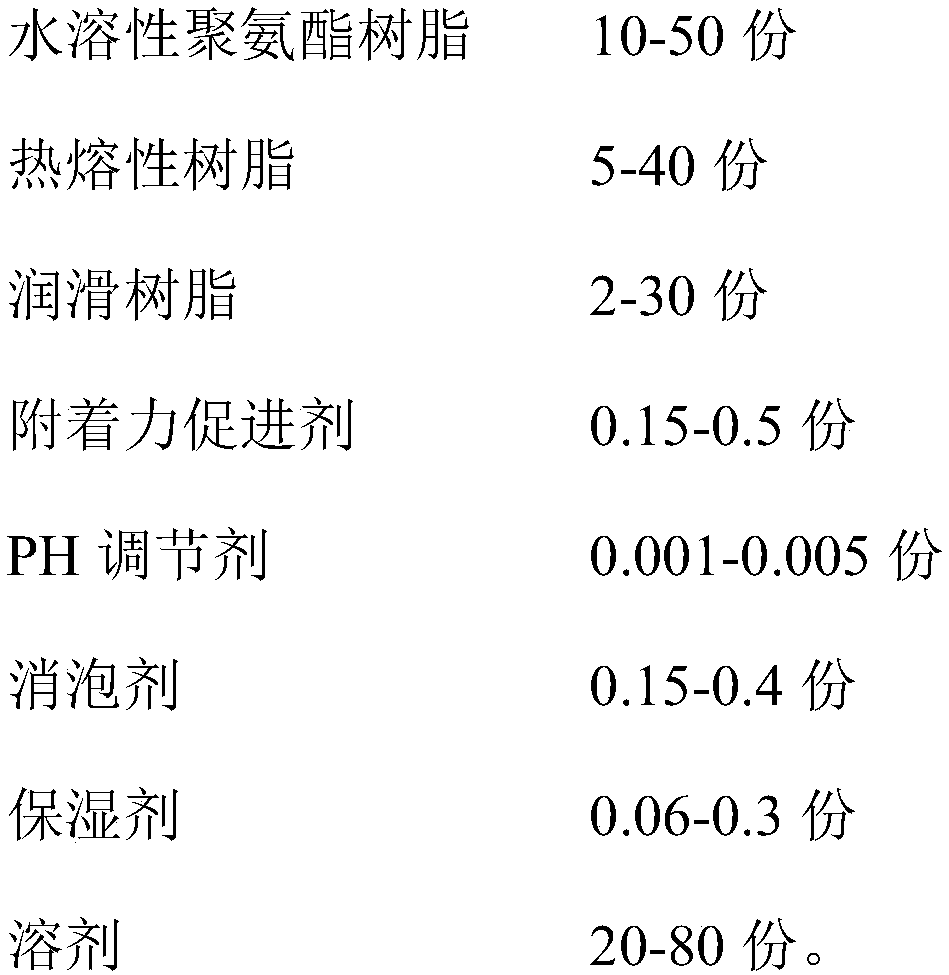

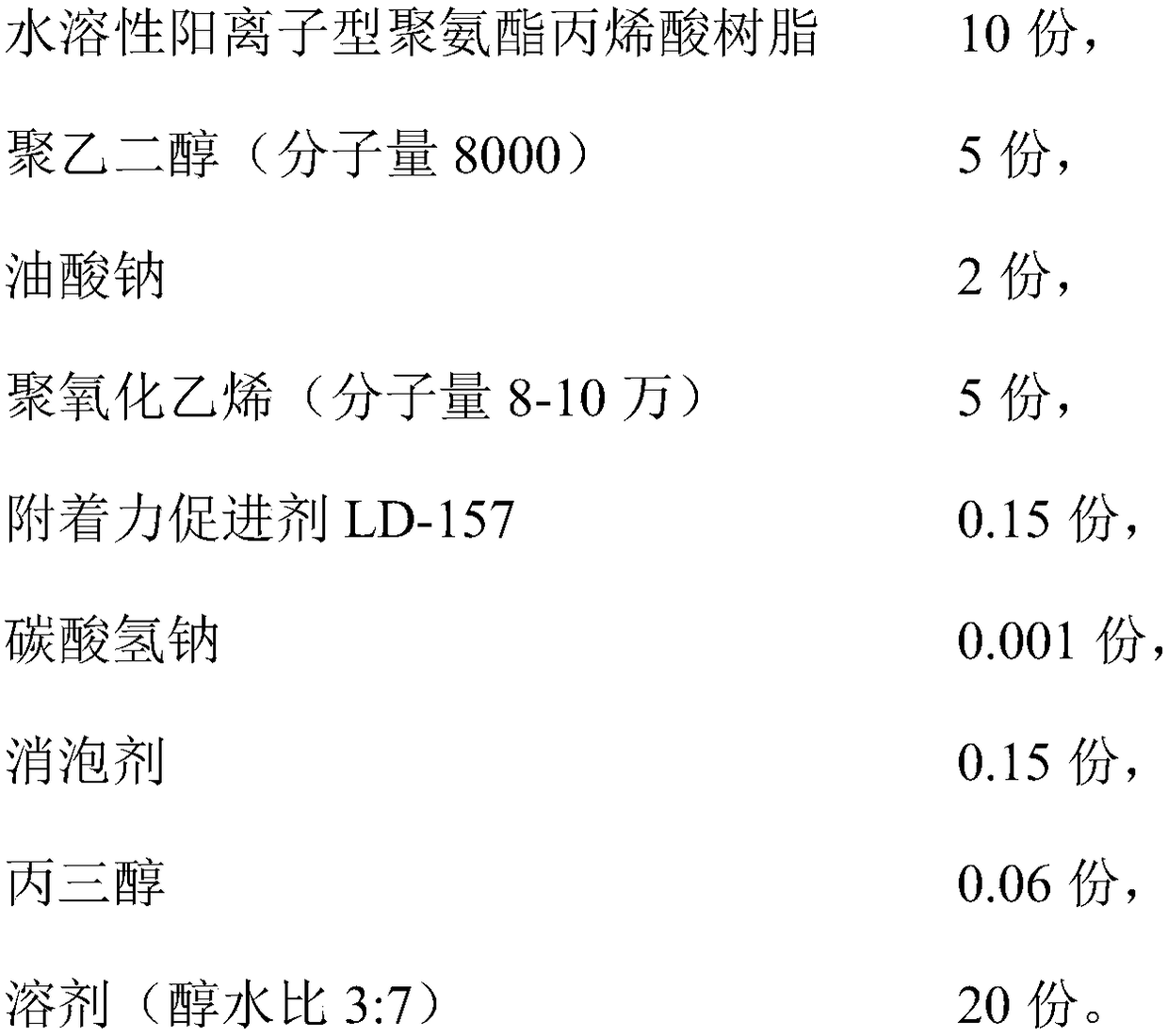

[0022] Weigh each component by mass percentage:

[0023]

[0024] Preparation:

[0025] 1. In the stirred tank, prepare the solvent according to the alcohol-water ratio of 3:7;

[0026] 2. Add proportioning solvent, water-soluble cationic polyurethane acrylic resin, polyethylene glycol (molecular weight 8000), sodium oleate, polyethylene oxide (molecular weight 80,000-100,000), adhesion promoter LD-157, Sodium bicarbonate, glycerin, stir for 20min evenly;

[0027] 3. Add defoamer and stir for more than 30 minutes to make the coating evenly mixed, which is water-based polyurethane coating.

Embodiment 2

[0029] Weigh each component by mass percentage:

[0030]

[0031]

[0032] Preparation:

[0033] 1. In the stirred tank, prepare the solvent according to the alcohol-water ratio of 3:7;

[0034] 2. Add proportioning solvent, water-soluble cationic polyurethane acrylic resin, polyethylene glycol (molecular weight 3000), sodium oleate, polyethylene oxide (molecular weight 80,000-100,000), adhesion promoter LD-157, Potassium hydroxide, glycerol, stirred for 20min evenly;

[0035] 3. Add defoamer and stir for more than 30 minutes to make the coating evenly mixed, which is water-based polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com