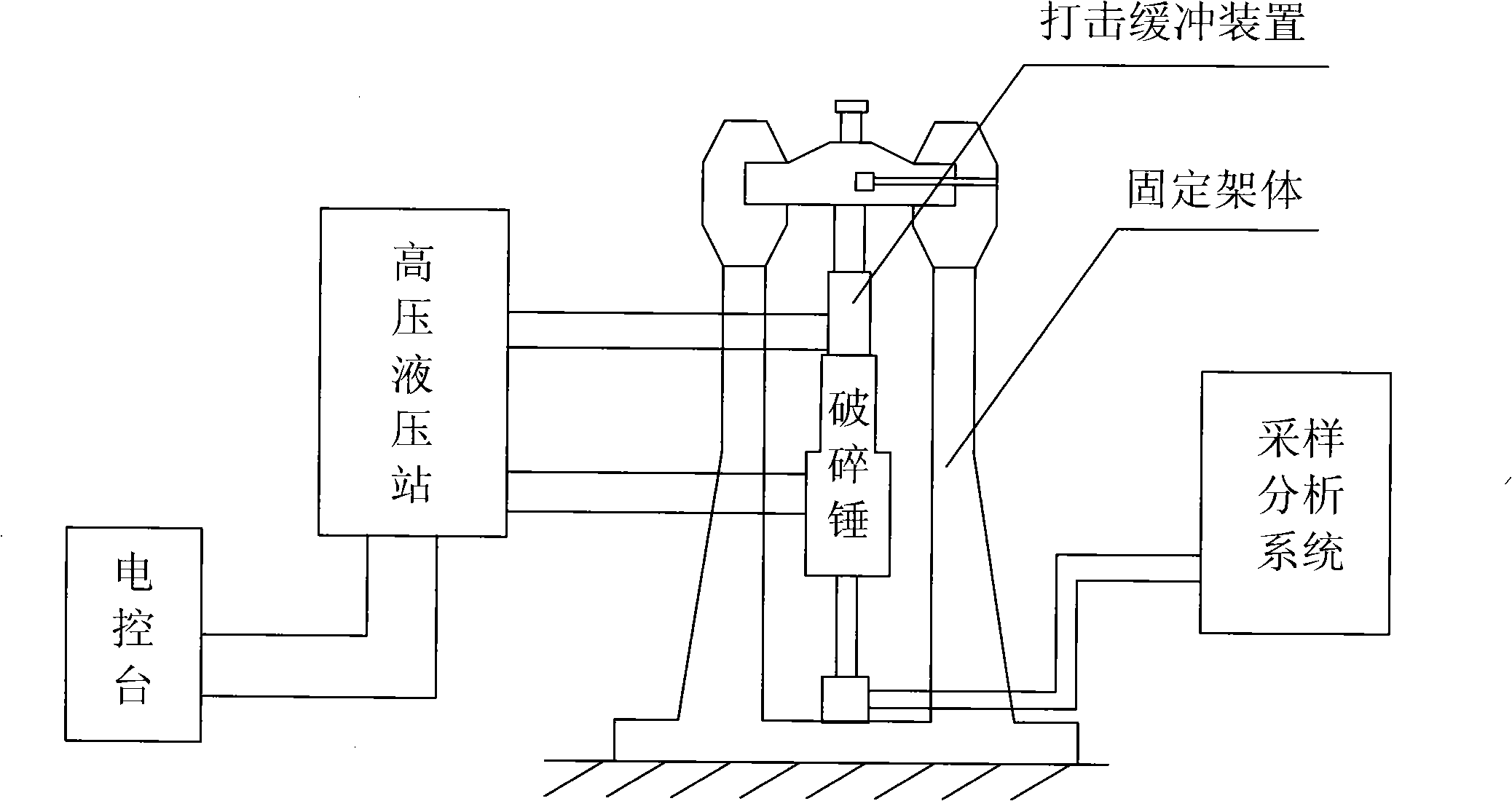

Hydraulic breaking hammer performance measurement system

A hydraulic breaker and testing system technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve problems such as poor accuracy, increase the difficulty of work, increase costs, etc., to avoid poor lubrication and accurate detection results. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] As a second embodiment of the present invention, a flow transmitter FC and another pressure transmitter PC are arranged in parallel between the inlet pipe of the pressure sensor in the sampling and analysis system and the data acquisition card 1 . After the pressure sensor of the hitting piston is hit by the breaker, the hitting piston turns the hydraulic oil in the cylinder into high-pressure oil, and the pressure sensor converts the pressure into a pressure sensing signal, which is transmitted through the pressure transmitter PC 2 The pressure sensing signal is converted into a pressure data signal and transmitted to the data acquisition card. After the data acquisition card collects the pressure data signal, it is transmitted to the industrial computer, and the industrial computer displays and calculates the data signal. The flow transmitter FC converts the hydraulic oil flow of the pressure sensor inlet pipe into a flow data signal and transmits it to the data acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com