Plane coil

A planar coil, coil technology, applied in the direction of transformer/inductor coil/winding/connection, preventing/reducing unwanted electrical/magnetic influence, transformer, etc., can solve problems such as hindering thinning and large outer diameter of stranded wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

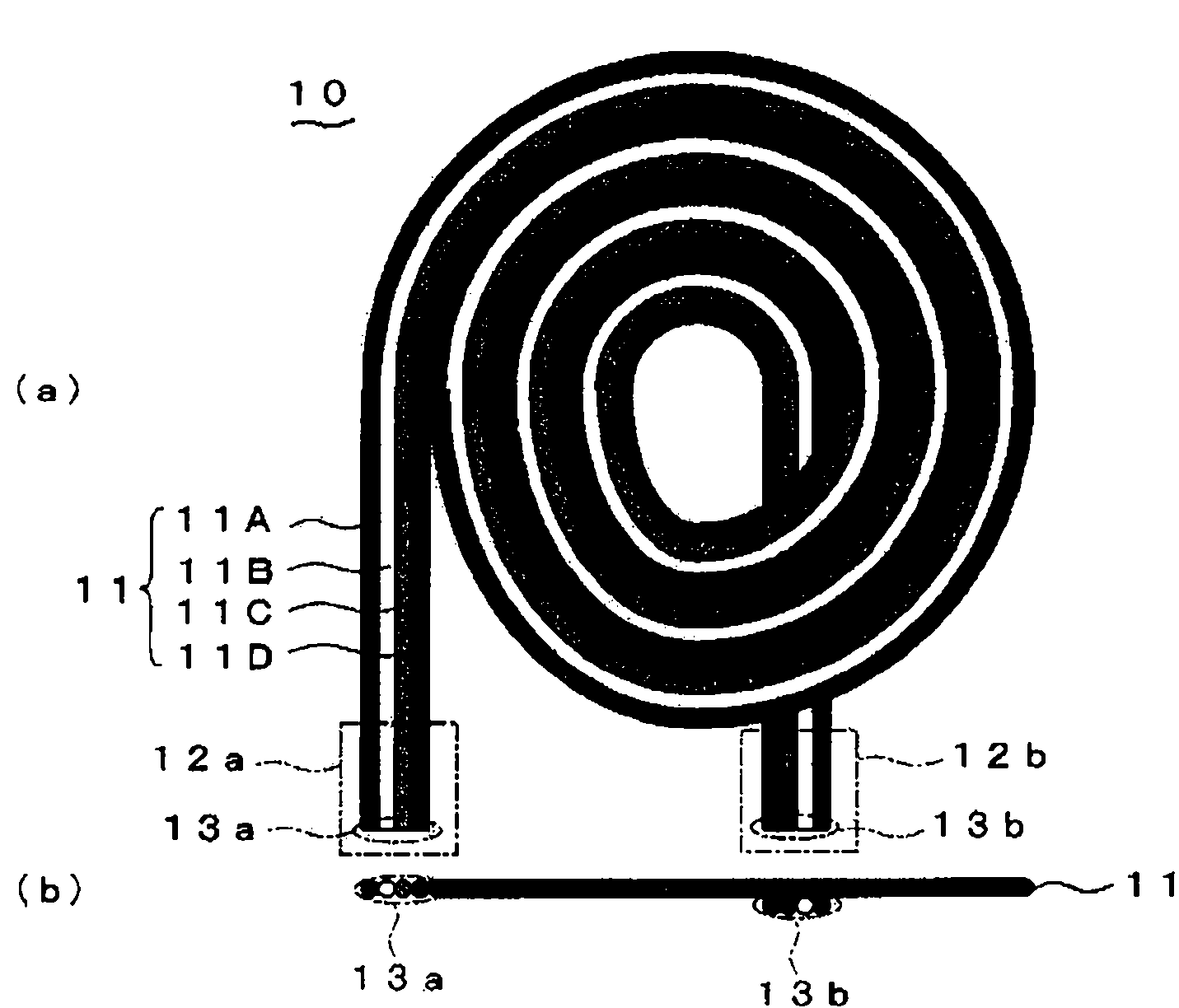

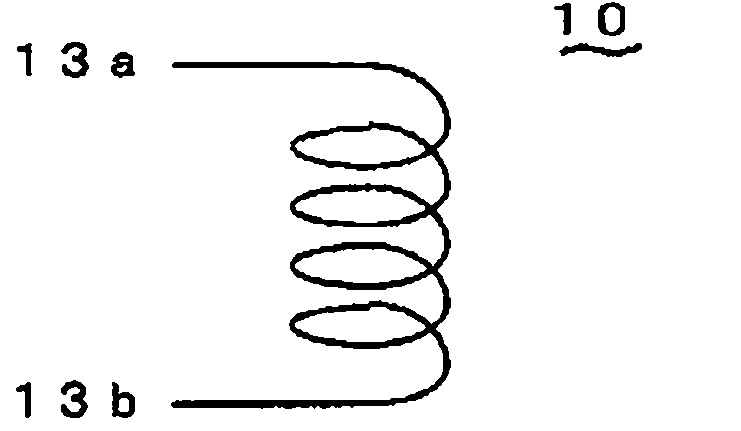

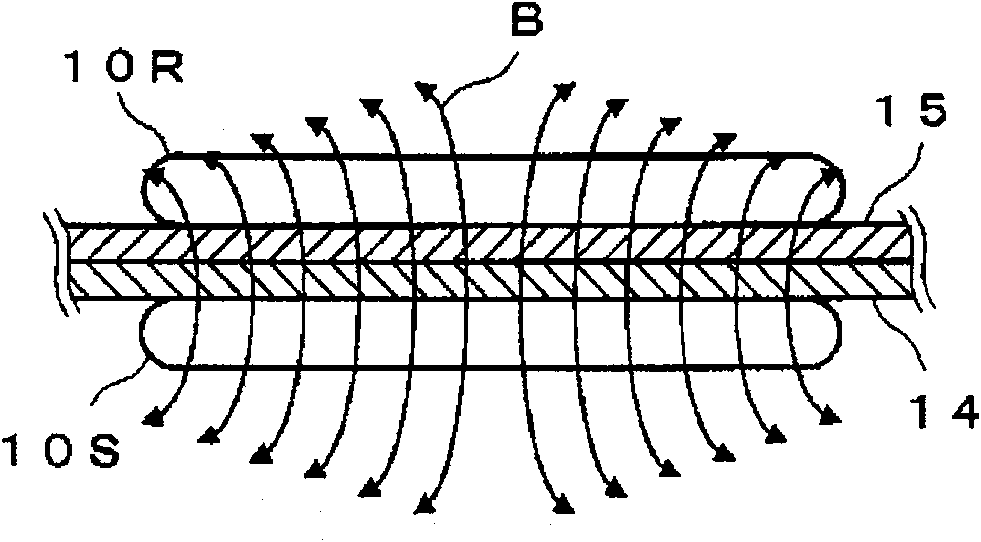

[0052] figure 1 (a) and figure 1(b) shows the structure of the planar coil 10 which concerns on 1st Embodiment which actualized this invention. This planar coil 10 is formed by arranging a plurality of conductive wires 11A, 11B, 11C, and 11D (hereinafter collectively referred to as conductive wires 11 ) parallel to each other in a substantially planar shape and wound in a spiral shape. Ends 13 a , 13 b of conductive wire 11 are located on coil lead-outs 12 a , 12 b of planar coil 10 . The ends 13a of the parallel conductive wires 11 are electrically connected at the coil lead-out part 12a, and the respective ends 13b of the other ends are electrically connected at the other coil lead-out part 12b, so that the conductive wires 11 are connected in parallel. The conductive wires 11 are insulated from each other between the end portion 13a and the end portion 13b. The number of conductive wires 11 is not limited to four, but can be more than two, and the diameter and length c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com