Method for judging bituminous mixture skeleton structure

A technology of asphalt mixture and skeleton structure, which is applied in the direction of analysis materials, preparation of test samples, measuring devices, etc., can solve the problems of not fully considering the resistance of skeleton structure to external loads, etc., and achieve easy operation, simple test steps, The effect of simple test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

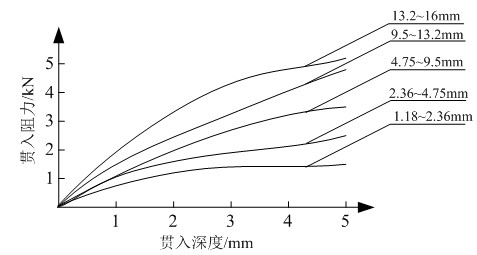

[0033] The gradation to be determined is shown in Table 1. According to the gradation in Table 1, 3000g of aggregate mixture is prepared, and the mass of each grade of aggregate is calculated according to Table 1. The results are shown in Table 2.

[0034] Table 1 Aggregate gradation to be determined

[0035] Particle size / mm Passing rate / % 16 100 13.2 94 9.5 63 4.75 26 2.36 20 1.18 18 0.6 15 0.3 13

[0036] Table 2 The quality of aggregates in each grade

[0037] particle size 13.2~16mm 9.5~13.2mm 4.75~9.5mm 2.36~4.75mm 1.18~2.36mm 0.6~1.18mm 0.3~0.6mm <0.3mm

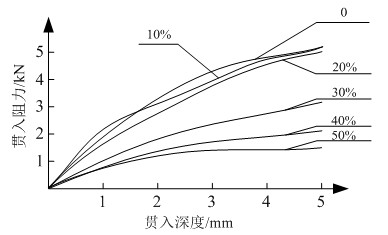

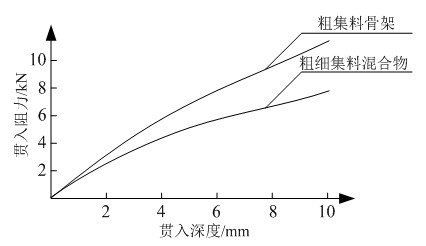

[0038] Put 3000g of coarse and fine aggregate mixture in three layers into a steel test mold with an inner diameter of 152mm and a height of 170mm, and put 1000g of aggregate in each layer. A compressive load of 10 kN is applied to the aggregate in the test mold. Apply a penetration load of 1 mm / min to the aggregate mixture on the penet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com